Fast setting cement and its preparation method and application

A pozzolanic and cement technology, applied in the field of fast-setting cement and its preparation, can solve the problems of high cost, cumbersome operation, complicated process, etc., and achieve the effects of low cost, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

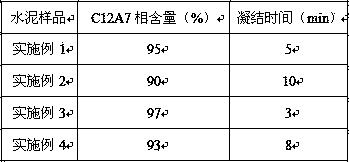

Embodiment 1

[0028] Embodiment 1: A kind of fast hardening cement

[0029] The fast-setting hard cement consists of the following raw materials in percentage terms: Al 2 o 3 56%, CaO 43%, SiO 2 0.5%, Fe 2 o 3 0.5%.

Embodiment 2

[0030] Embodiment 2: A kind of quick setting cement

[0031] The fast-setting hard cement consists of the following raw materials in percentage terms: Al 2 o 3 62%, CaO 37%, SiO 2 0.5%, Fe 2 o 3 0.5%.

Embodiment 3

[0032] Embodiment 3: a kind of fast hardening cement

[0033] The fast-setting hard cement consists of the following raw materials in percentage terms: Al 2 o 3 58%, CaO 41.49%, SiO 2 0.01%, Fe 2 o 3 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com