Preparation method of impermeable ceramic material capable of rapidly reacting with low-melting-point oxide

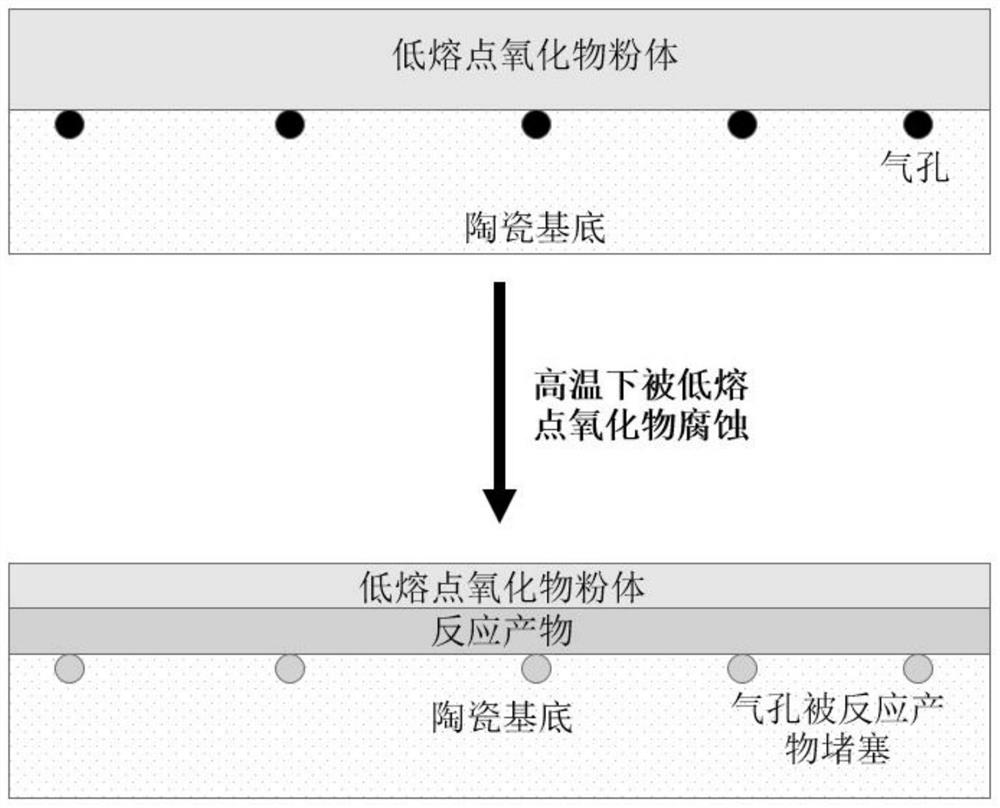

A fast-reacting, ceramic material technology, applied in the field of ceramic material preparation, can solve the problems of low melting point oxide corrosion, failure, etc., and achieve the effect of improving permeability and permeability resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

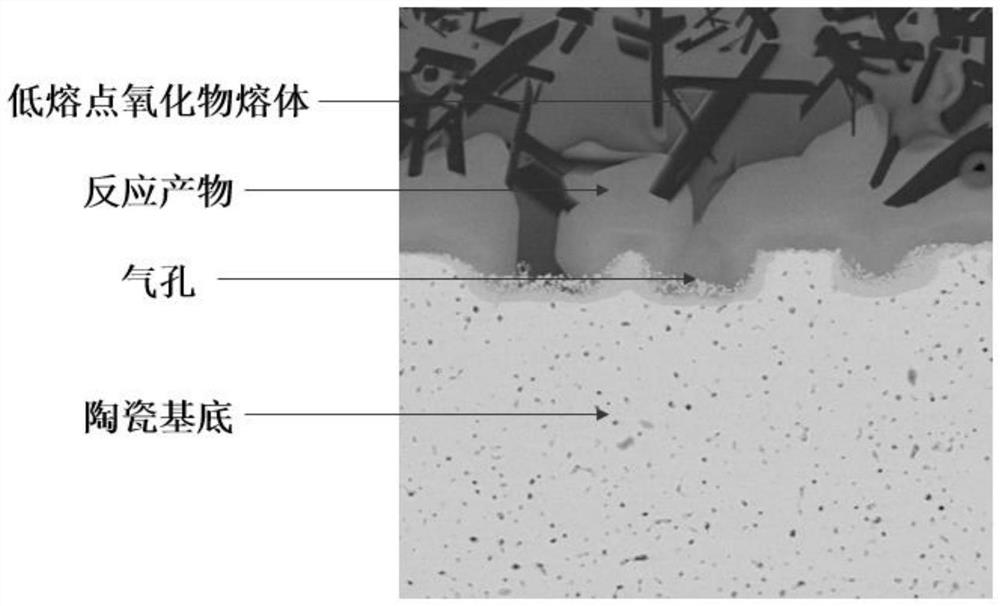

Method used

Image

Examples

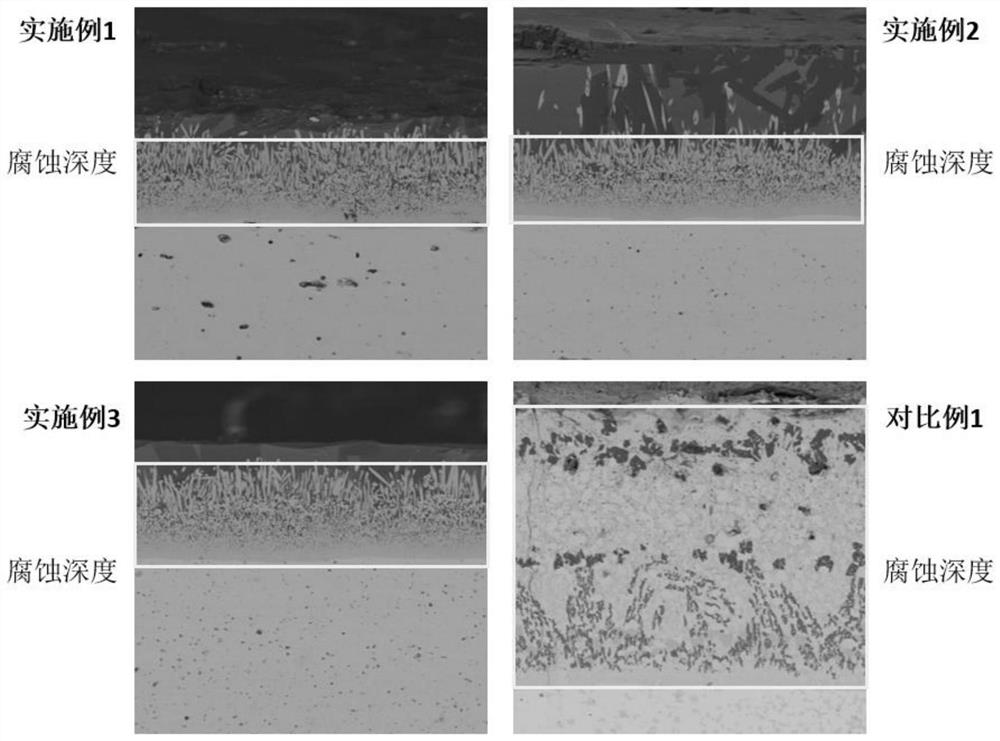

Embodiment 1

[0027] A method for preparing a ceramic material that reacts rapidly with a low melting point oxide and is resistant to penetration, comprising the following steps:

[0028] (1) Weigh La with a purity greater than 99% 2 O 3 , Y 2 O 3 , Nb 2 O 5 Powder, La 2 O 3 , Y 2 O 3 and Nb 2 O 5 The molar ratio of the powder is 0.5:1:0.5; the three powders are mixed evenly by a ball mill, the speed of the ball mill is 200 rpm, the ball milling time is 48h, and alcohol is used as the ball milling medium in the ball milling process. The total mass of the three powders and alcohol The mass ratio is 1:10 to obtain uniformly mixed slurry;

[0029] (2) The uniformly mixed slurry is dried at 90°C for 20h, pre-sintered at 1000°C for 10h and cooled to obtain initial powder;

[0030] (3) The initial powder was ground and passed through a 300-mesh sieve, according to LaY 2 NbO 7 The required porosity (5-15%), press the tablet under the conditions of a pressing pressure of 100MPa and a ...

Embodiment 2

[0034] A method for preparing a ceramic material that reacts rapidly with a low melting point oxide and is resistant to penetration, comprising the following steps:

[0035] (1) Weigh La with a purity greater than 99% 2 O 3 , Tm 2 O 3 , Nb 2 O 5 Powder, La 2 O 3 , Tm 2 O 3 and Nb 2 O 5 The molar ratio of the powder is 0.4:1:0.4; the three powders are mixed evenly by a ball mill, the speed of the ball mill is 500 rpm, the ball milling time is 24h, and alcohol is used as the ball milling medium in the ball milling process. The total mass of the three powders and alcohol The mass ratio is 1:30 to obtain a uniformly mixed slurry;

[0036] (2) drying the uniformly mixed slurry at 100°C for 10h, pre-sintering at 900°C for 9h and cooling to obtain initial powder;

[0037] (3) Grind the initial powder and pass through a 350-mesh sieve, according to LaTm 2 NbO 7 The porosity requirement (5-15%), press the tablet under the conditions of a pressing pressure of 200MPa and a ...

Embodiment 3

[0040] A method for preparing a ceramic material that reacts rapidly with a low melting point oxide and is resistant to penetration, comprising the following steps:

[0041] (1) Weigh La with a purity greater than 99% 2 O 3 , Pr 2 O 3 , Nb 2 O 5 Powder, La 2 O 3 , Pr 2 O 3 and Nb 2 O 5 The molar ratio of the powder is 0.6:1:0.6; the three powders are mixed evenly by a ball mill, the speed of the ball mill is 360 rpm, the ball milling time is 30h, and alcohol is used as the ball milling medium in the ball milling process. The total mass of the three powders and alcohol The mass ratio is 1:26 to obtain uniformly mixed slurry;

[0042] (2) The uniformly mixed slurry was dried at 93°C for 16h, pre-sintered at 960°C for 9.3h and cooled to obtain initial powder;

[0043] (3) Grind the initial powder and pass through a 330-mesh sieve, according to LaPr 2 NbO 7 The required porosity (5-15%), press the tablet under the conditions of a pressing pressure of 160MPa and a hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com