Nuclear zirconium alloy cladding surface high temperature and corrosion resisting high-entropy alloy coating and preparing method thereof

A high-temperature corrosion-resistant, high-entropy alloy technology, which is applied in metal material coating technology, coating, ion implantation plating, etc., can solve the problems of poor bonding force between coating and zirconium alloy, poor corrosion resistance, etc., and achieve Excellent corrosion resistance and insolubility, excellent corrosion resistance, excellent high temperature corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

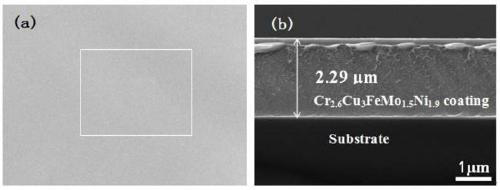

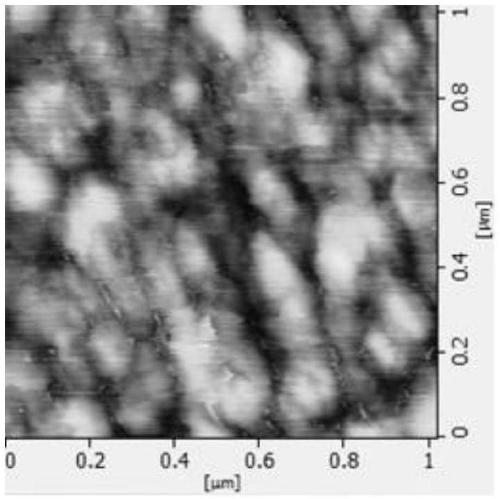

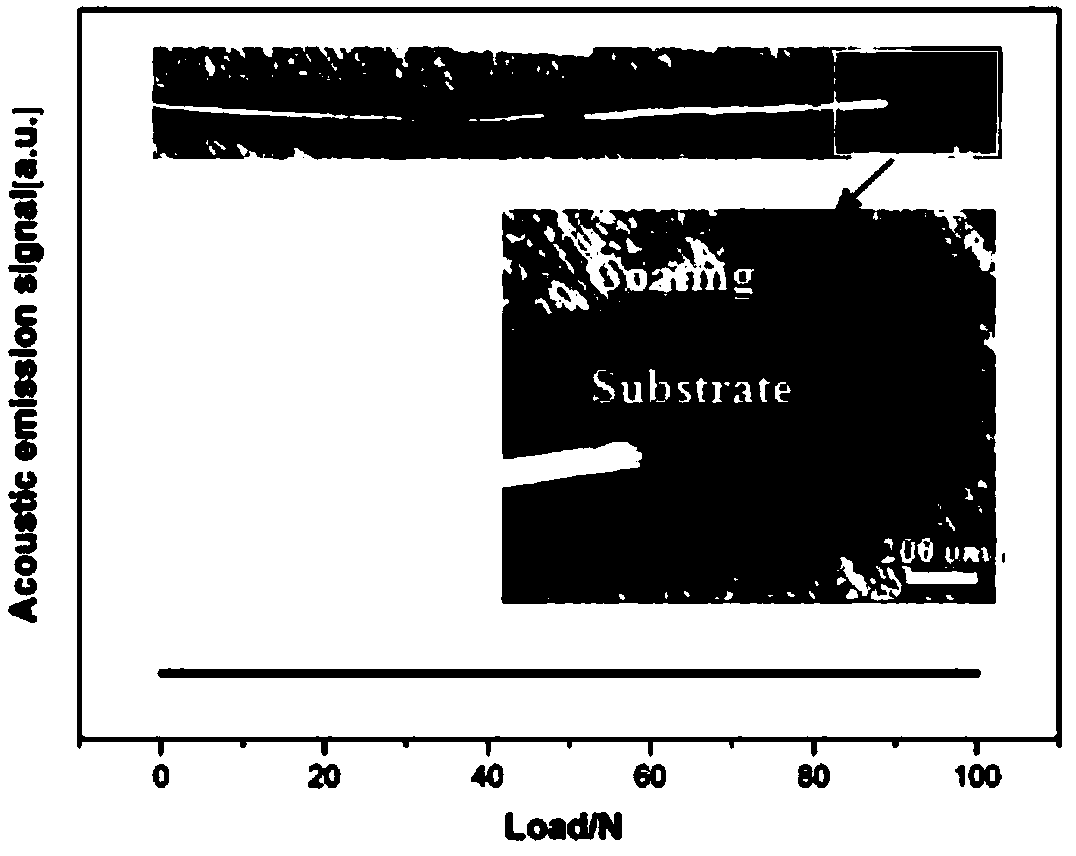

Embodiment 1

[0032] In this example, the CrCuFeMoNi high-entropy alloy coating was deposited on the surface of the Zr-4 alloy substrate using ultra-high vacuum multi-target co-sputtering technology, and the sputtering metal targets used had a uniform purity of 99.99%. %, the working gas Ar purity is 99.999%, and the specific preparation process includes the following steps:

[0033] (1) Base material pretreatment

[0034] The Zr-4 alloy is processed into a square sheet with a side length of 1 cm and a thickness of 3 mm, and the Zr-4 alloy substrate is sequentially polished with 240 mesh, 600 mesh, 1000 mesh, 1500 mesh, and 3000 mesh water abrasive paper from coarse to fine, and then Use a polishing paste to perform polishing on a metallographic polishing machine. After polishing, use acetone and absolute ethanol to ultrasonically clean for 15 minutes, and dry it for use.

[0035] (2) Reverse sputtering cleaning of substrate material

[0036] Place the pretreated substrate material on the...

Embodiment 2

[0042] In this example, the CrCuFeMoNi high-entropy alloy coating was deposited on the surface of the Zr-4 alloy substrate using ultra-high vacuum multi-target co-sputtering technology, and the sputtering metal targets used had a uniform purity of 99.99%. %, the working gas Ar purity is 99.999%, and the specific preparation process includes the following steps:

[0043] (1) Base material pretreatment

[0044] The Zr-4 alloy is processed into a square sheet with a side length of 1 cm and a thickness of 3 mm, and the Zr-4 alloy substrate is sequentially polished with 240 mesh, 600 mesh, 1000 mesh, 1500 mesh, and 3000 mesh water abrasive paper from coarse to fine, and then Use a polishing paste to perform polishing on a metallographic polishing machine. After polishing, use acetone and absolute ethanol to ultrasonically clean for 15 minutes, and dry it for use.

[0045] (2) Reverse sputtering cleaning of substrate material

[0046] Place the pretreated substrate material on the...

Embodiment 3

[0052] In this example, the CrCuFeMoNi high-entropy alloy coating was deposited on the surface of the Zr-4 alloy substrate using ultra-high vacuum multi-target co-sputtering technology, and the sputtering metal targets used had a uniform purity of 99.99%. %, the working gas Ar purity is 99.999%, and the specific preparation process includes the following steps:

[0053] (1) Base material pretreatment

[0054] The Zr-4 alloy is processed into a square sheet with a side length of 1 cm and a thickness of 3 mm, and the Zr-4 alloy substrate is sequentially polished with 240 mesh, 600 mesh, 1000 mesh, 1500 mesh, and 3000 mesh water abrasive paper from coarse to fine, and then Use a polishing paste to perform polishing on a metallographic polishing machine. After polishing, use acetone and absolute ethanol to ultrasonically clean for 20 minutes, and then dry it for use.

[0055] (2) Reverse sputtering cleaning of substrate material

[0056] Place the pretreated substrate material o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com