Method for preparing light inductor

A light sensor, light sensing technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of photocurrent attenuation, low photocurrent stability, and the inability of light sensors to meet the application, and improve reliability. the effect of reducing the cost of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

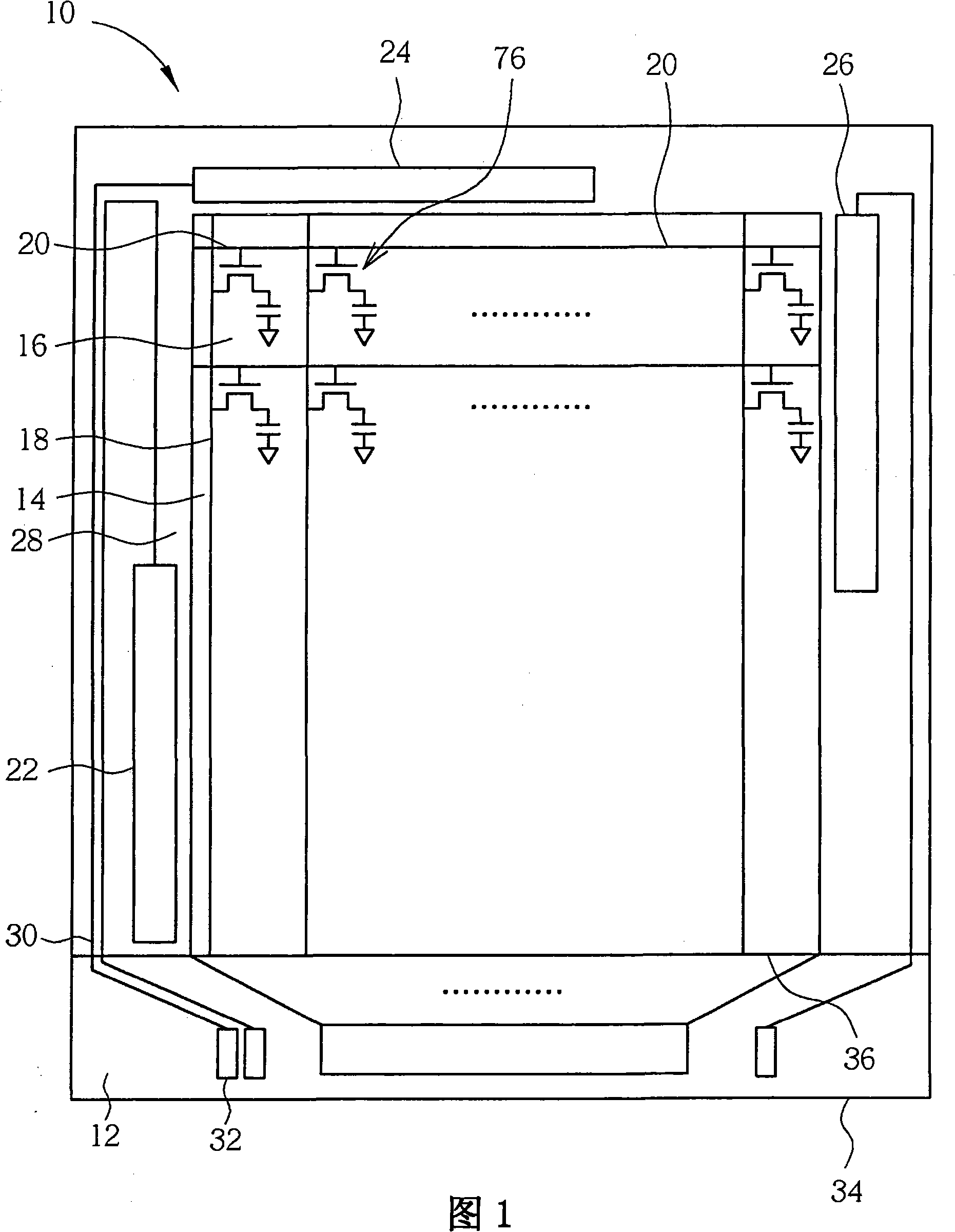

[0051] Please refer to FIG. 1 . FIG. 1 is a schematic diagram of applying the light sensor of the present invention to an amorphous silicon TFT display panel. The amorphous silicon TFT display panel 10 includes a lower substrate 34 and an upper substrate 36. When the amorphous silicon TFT display panel 10 is a liquid crystal display panel, the lower substrate 34 and the upper substrate 36 are usually called an array substrate and a color filter substrate respectively. . However, the TFT display panel 10 can also be other types of flat display panels, such as organic light emitting display panels. The amorphous silicon TFT display panel 10 further includes a display area 14 and a peripheral circuit area 12, wherein a plurality of scanning lines 20 and signal lines 18 are arranged in the display area 14, defining pixels 16 arranged in an array, and each pixel 16 includes A TFT device 76 is electrically connected to the scan line 20 and the signal line 18 . In addition, the TFT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com