Method for preparing low-density high-performance SiO2 aerogel at constant pressure

A low-density, aerogel technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of high cost of supercritical drying, high drying density, high thermal conductivity, and expensive silicon source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

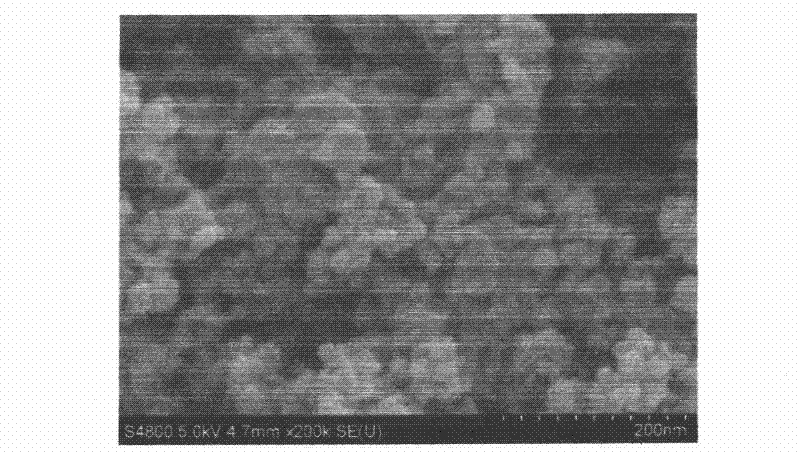

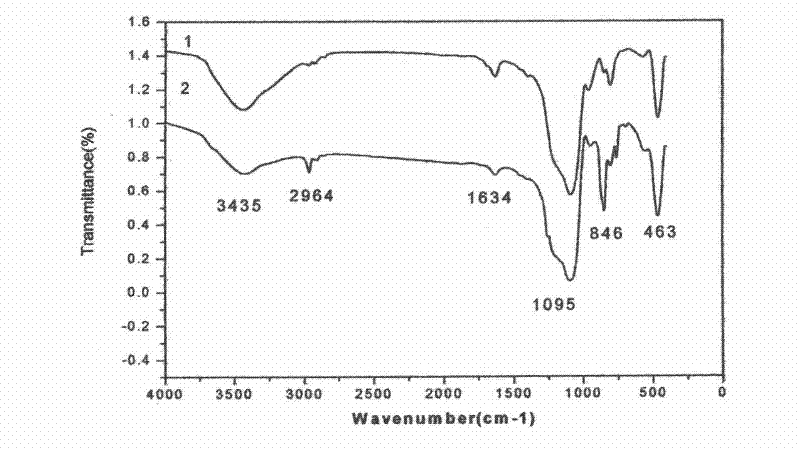

Image

Examples

Embodiment 1

[0020] A low-density SiO prepared under atmospheric pressure 2 The method of airgel, comprises the following steps:

[0021] 1), two-step sol-gel method, the mixed solution of industrial water glass and deionized water is ion-exchanged with cation exchange resin to remove Na + Finally, the pH value was adjusted to 1 with 1mol / L HCl to obtain a sol, and the sol was left to stand for 10 hours, and then NH 3 ·H 2 O adjusted the pH value to 5 to obtain a wet gel,

[0022] 2), step-by-step aging and solvent exchange, put the wet gel in the aging solution mixed with ethyl orthosilicate and ethanol for aging for 1d, the mass ratio or volume ratio of the wet gel and the aging solution is 1:1-2 , place the aged wet gel in n-hexane for solvent exchange for 3d, the mass ratio or volume ratio of the aged wet gel to n-hexane is 1:1-2, the aging and solvent exchange process is: aging 2d-solvent exchange 1d-aging 2d-solvent exchange 2d, the ratio of aging solution V(TEOS):V(EtOH) is 3:7 ...

Embodiment 2

[0027] A low-density SiO prepared under atmospheric pressure 2 The method of airgel, comprises the following steps:

[0028] 1), two-step sol-gel method, the mixed solution of industrial water glass and deionized water is ion-exchanged with cation exchange resin to remove Na + Finally, the pH value was adjusted to 1.5 with 1mol / L HCl to obtain a sol, which was allowed to stand for 11 hours, and then NH 3 ·H 2 O adjusted the pH value to 5.5 to obtain a wet gel,

[0029] 2), step-by-step aging and solvent exchange, place the wet gel in the aging solution mixed with ethyl orthosilicate and ethanol for aging for 3 days, the volume ratio of the wet gel and the aging solution is 1:1-2, and the aging After the wet gel is placed in n-hexane for solvent exchange for 3 days, the volume ratio of wet gel and n-hexane after aging is 1:1~2, and the aging and solvent exchange process is: aging 2d-solvent exchange 1d-aging 2d-solvent Exchange 2d, the ratio of aging solution V(TEOS):V(EtOH...

Embodiment 3

[0034] A low-density SiO prepared under atmospheric pressure 2 The method of airgel, comprises the following steps:

[0035] 1), two-step sol-gel method, the mixed solution of industrial water glass and deionized water is ion-exchanged with cation exchange resin to remove Na + Finally, the pH value was adjusted to 2 with 1mol / L HCl to obtain a sol, which was allowed to stand for 12 hours, and then NH 3 ·H 2 O adjusted the pH value to 6 to obtain a wet gel,

[0036]2), step-by-step aging and solvent exchange, place the wet gel in the aging solution mixed with ethyl orthosilicate and ethanol for aging for 6 days, the volume ratio of the wet gel and the aging solution is 1:1-2, and the aging After the wet gel is placed in n-hexane for solvent exchange for 3 days, the volume ratio of wet gel and n-hexane after aging is 1:1~2, and the aging and solvent exchange process is: aging 2d-solvent exchange 1d-aging 2d-solvent Exchange 2d, the ratio of aging solution V(TEOS):V(EtOH) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com