Heat exchanger support structure and heat exchanger supporting method

a technology of heat exchanger and support structure, which is applied in the direction of machines/engines, transportation and packaging, light and heating apparatus, etc., can solve the problems of its manufacturing process and increase the cost of its assembly, and achieve the effect of reducing the manufacturing process and manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Throughout the following detailed description, similar reference characters and numbers refer to similar elements in all figures of the drawings, and their descriptions are omitted for eliminating duplication.

[0038] A heat exchanger support structure of an embodiment according to the present invention will be described with reference to the accompanying drawings. In this description, the terms “right”, “left”, “front” and “rear” are those identified with respect to a vehicle body, not to those in the drawings.

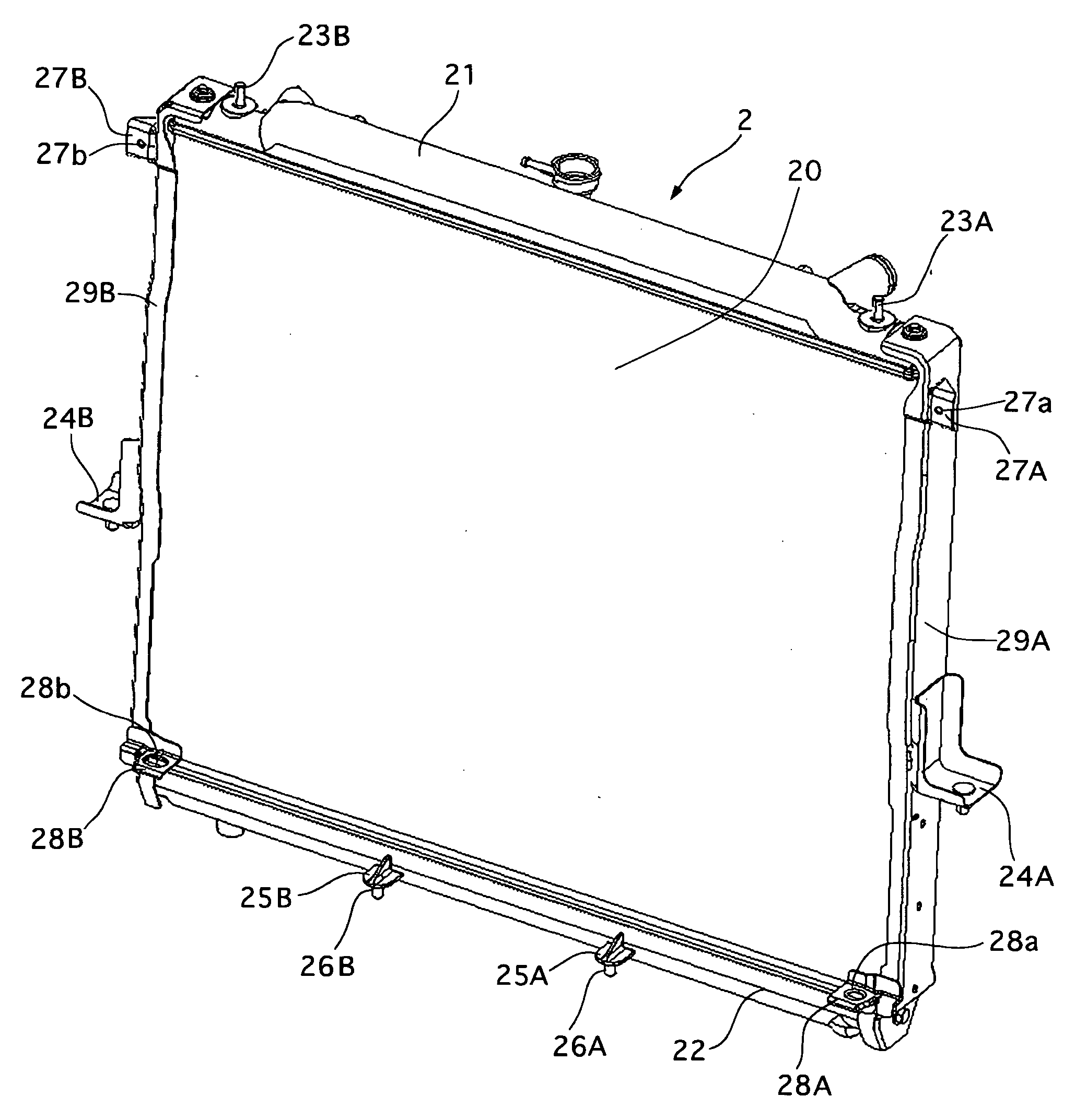

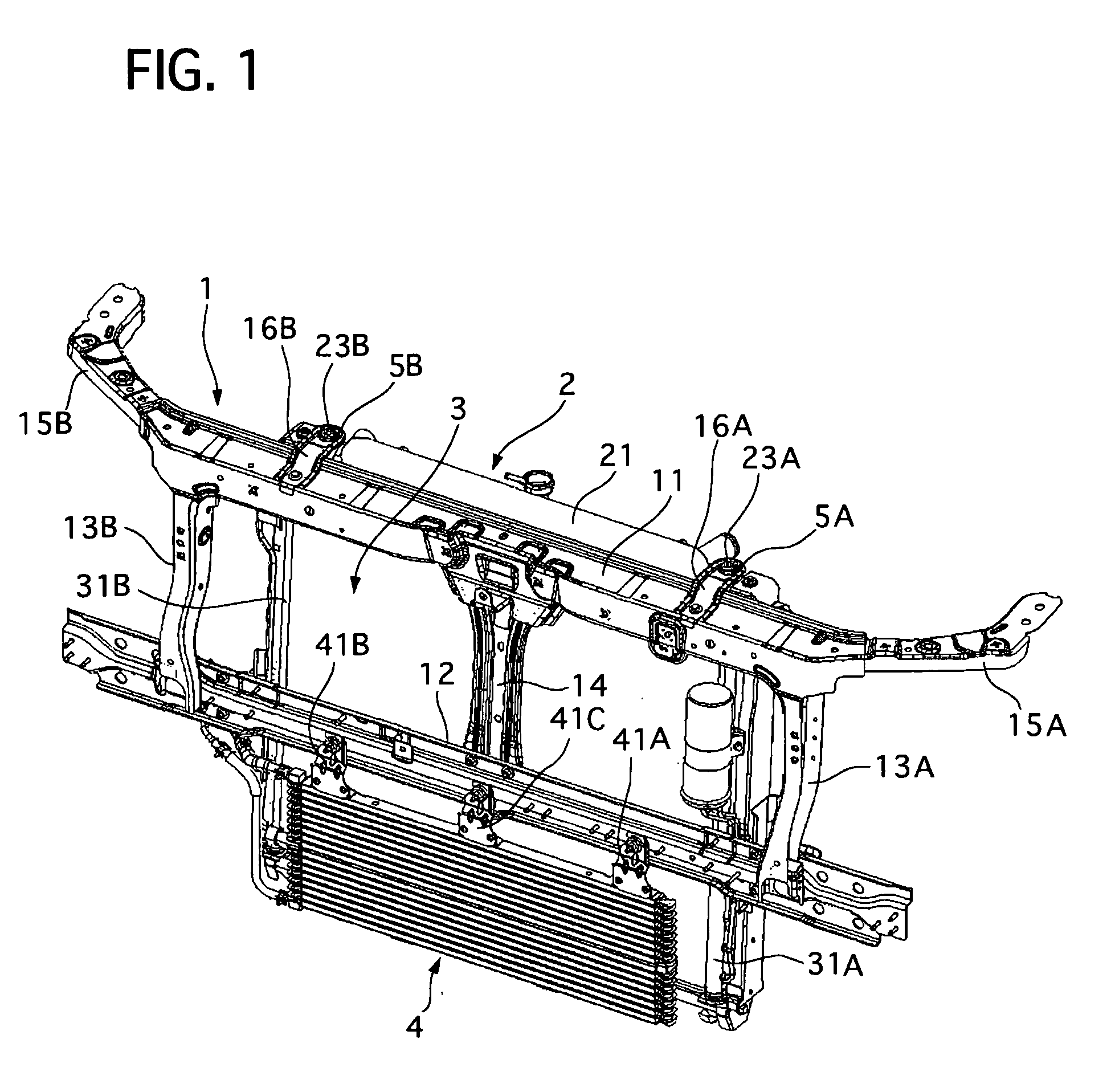

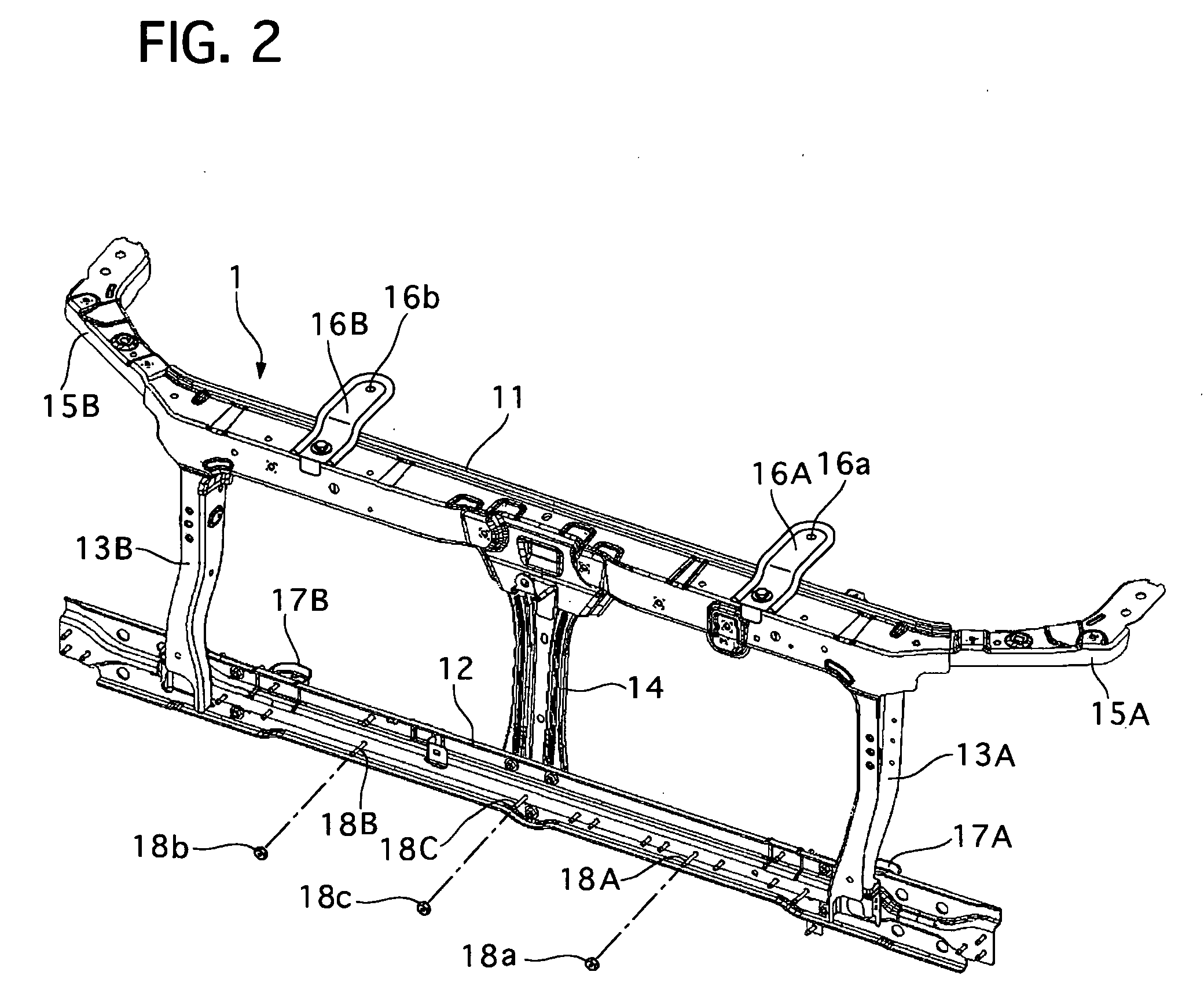

[0039] Referring to FIG. 1, there is shown the heat exchanger support structure of the embodiment, which is attached to a front portion of a not-shown vehicle body of a motor vehicle.

[0040] The heat exchanger support structure includes a radiator core support 1 fixed to the front portion of the vehicle body, a radiator 2 arranged at a rear side of the radiator core support 1, a condenser 3 arranged between the radiator core support 1 and the radiator 2, and an oil coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com