Preparation method of 1,4,5,8-octane tetranitrile

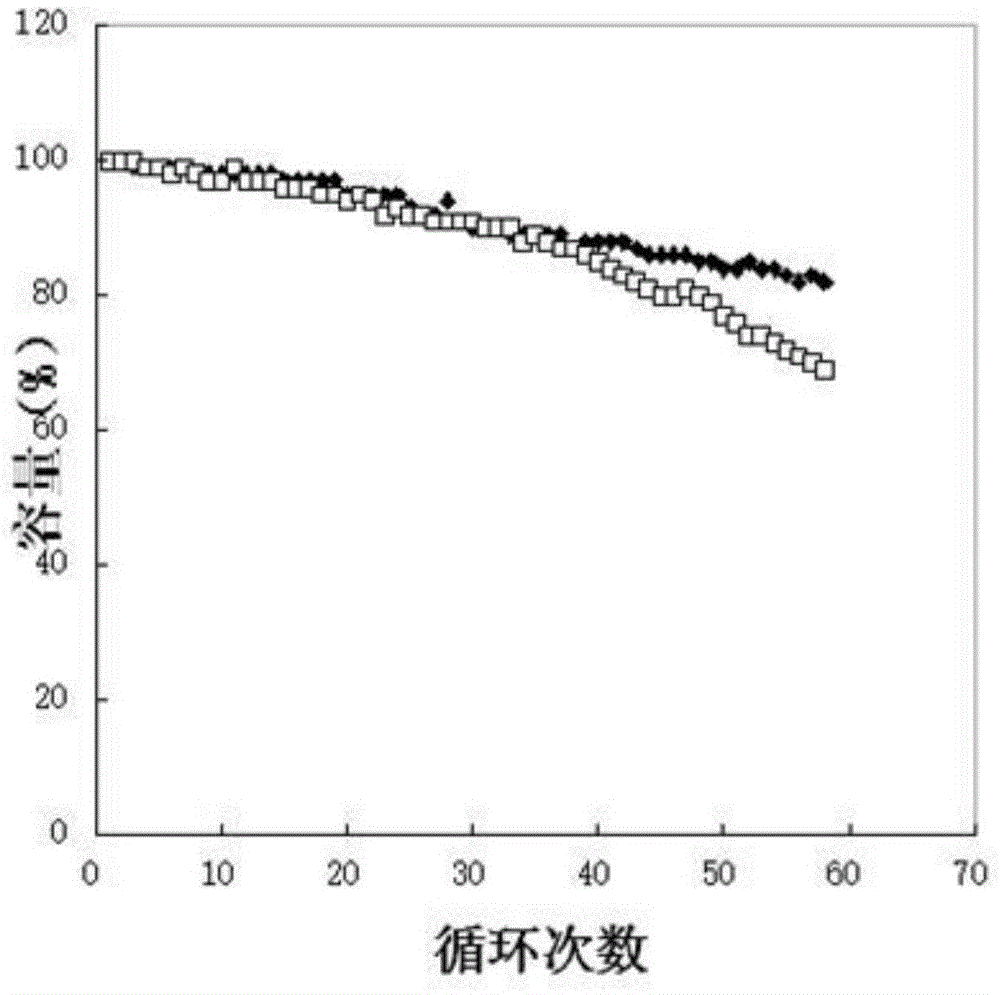

A technology of octane tetranitrile and succinonitrile, which is applied in the field of compound preparation, can solve the problems of industrialization difficulties, influence on battery performance, and low safety of preparation process, and achieve low battery life, prevent capacity reduction, and high acid value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

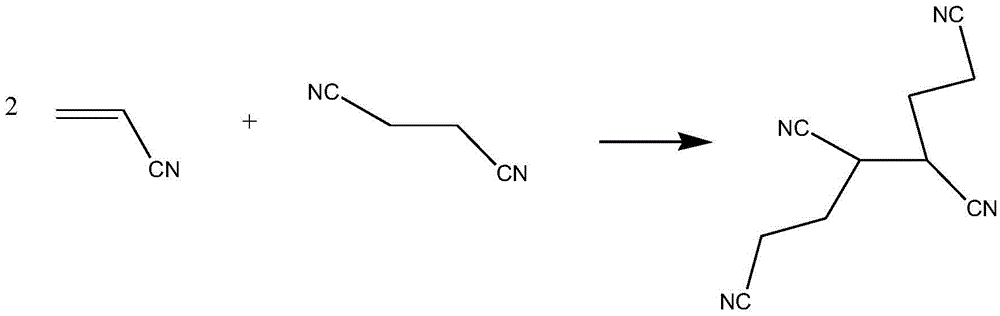

[0027] Step 1, adding potassium tert-butoxide and toluene into a reaction vessel, and dispersing into a uniform suspension, and then heating the suspension to 70°C;

[0028] Step 2, add succinonitrile to the suspension, keep the temperature of the suspension consistent with the temperature of step 1 during the process of adding succinonitrile, when a light yellow solid is precipitated, heat the reaction system to 100°C and continue the reaction for 5 hours , after the reaction is finished, add ice water to cool down to 5 degrees Celsius, then filter and wash the filter cake with water;

[0029] Step 3, add the filter cake obtained in step 2 to aqueous sodium hydroxide solution, then add toluene, tert-butylcatecholammonium chloride, and benzyltriethylammonium chloride in sequence and stir to obtain a mixed solution, and then add to the mixed solution Acrylonitrile, in the process of adding toluene, tert-butylcatecholammonium chloride, benzyltriethylammonium chloride and acrylon...

Embodiment 2

[0035] Step 1, adding potassium tert-butoxide and toluene into a reaction vessel, and dispersing into a uniform suspension, and then heating the suspension to 50°C;

[0036] Step 2, add succinonitrile to the suspension, keep the temperature of the suspension consistent with the temperature of step 1 during the process of adding succinonitrile, when a light yellow solid is precipitated, heat the reaction system to 80°C and continue the reaction for 1 hour , after the reaction is finished, add ice water to cool down to 10 degrees Celsius, then filter and wash the filter cake with water;

[0037] Step 3, add the filter cake obtained in step 2 to aqueous sodium hydroxide solution, then add toluene, tert-butylcatecholammonium chloride, and benzyltriethylammonium chloride in sequence and stir to obtain a mixed solution, and then add Acrylonitrile, in the process of adding toluene, tert-butylcatecholammonium chloride, benzyltriethylammonium chloride and acrylonitrile, the temperature...

Embodiment 3

[0043] Step 1, adding potassium tert-butoxide and toluene into a reaction vessel, and dispersing into a uniform suspension, and then heating the suspension to 60°C;

[0044] Step 2, add succinonitrile to the suspension, keep the temperature of the suspension consistent with the temperature of step 1 during the process of adding succinonitrile, when a light yellow solid is precipitated, heat the reaction system to 90°C and continue the reaction for 3 hours , after the reaction is finished, add ice water to cool down to 8 degrees Celsius, then filter and wash the filter cake with water;

[0045] Step 3, add the filter cake obtained in step 2 to aqueous sodium hydroxide solution, then add toluene, tert-butylcatecholammonium chloride, and benzyltriethylammonium chloride in sequence and stir to obtain a mixed solution, and then add to the mixed solution Acrylonitrile, in the process of adding toluene, tert-butylcatecholammonium chloride, benzyltriethylammonium chloride and acryloni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com