Preparation method of all-solid-state battery interface layer and all-solid-state battery

An all-solid-state battery and interface layer technology, which is applied in the direction of lithium batteries, secondary batteries, solid electrolytes, etc., can solve the problems of interface layer loss, SN melting point reduction, etc., to suppress side reactions, improve stability, and reduce interface The effect of impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

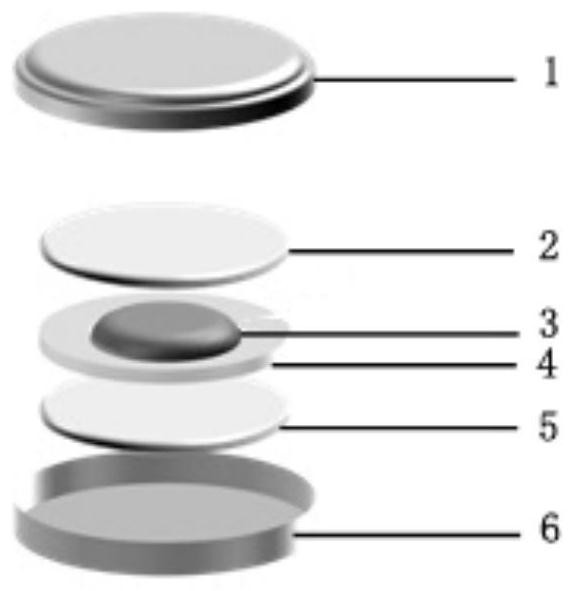

[0037] The invention provides a method for preparing an interface layer of an all-solid-state battery, the interface layer is arranged between a solid electrolyte and an electrode, and the method includes the following steps:

[0038] Step 1, heating and dissolving lithium salt, a stabilizer for stabilizing lithium, and succinonitrile and mixing to obtain a mixed solution;

[0039] Step 2, adding the polymer into the mixed solution, dissolving and mixing, and cooling to obtain a gel state interface layer; the polymer includes: one of polyethylene oxide, polyvinyl alcohol, and polyacrylonitrile or two or more.

[0040] In some embodiments, the stabilizer is fluoroethylene carbonate (FEC) or LiNO 3 .

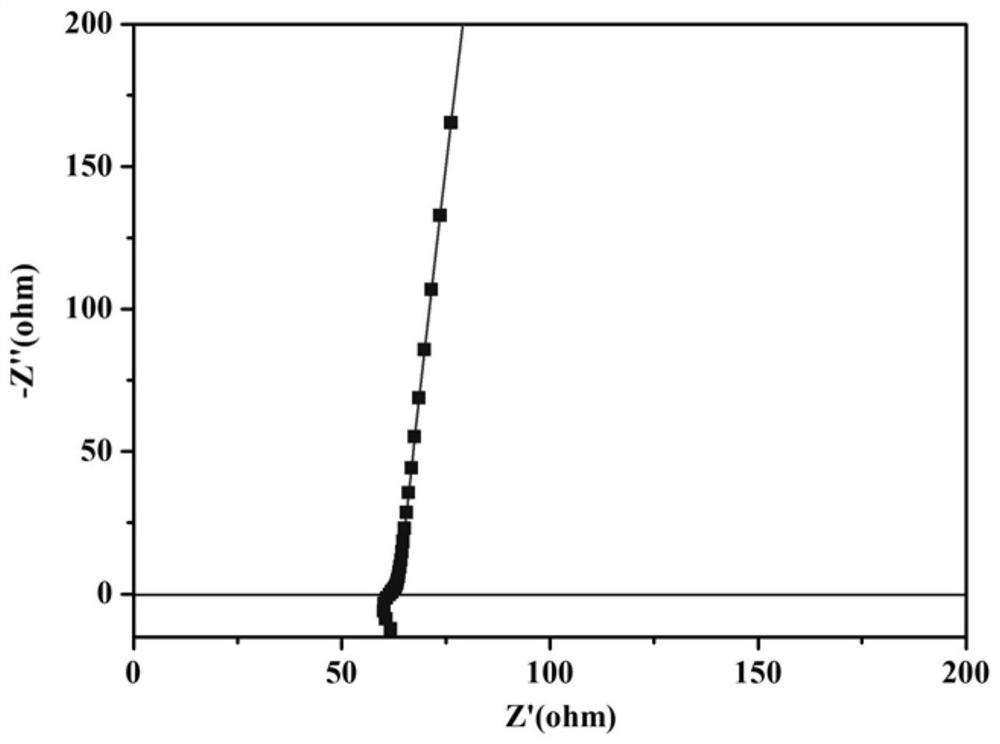

[0041] Succinonitrile (SN) is solid at room temperature with a melting point of 55-60°C. SN has a strong ability to dissolve lithium salts. After adding a small amount of lithium salts, the ion conductivity at room temperature can reach 10 -3S / cm order of magnitude. As a plas...

Embodiment 1

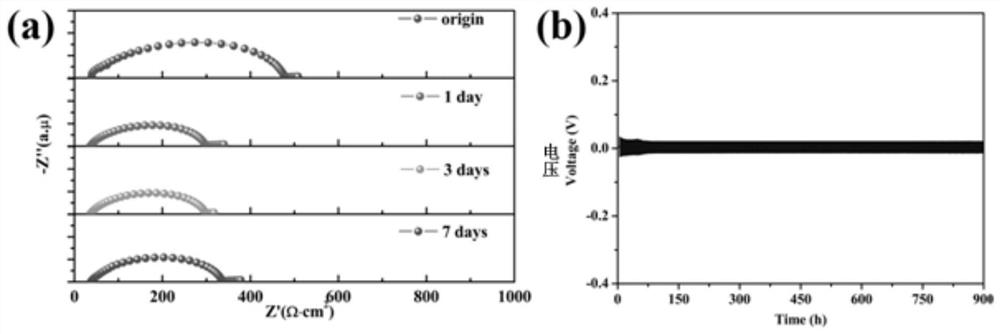

[0050] Add succinonitrile and 5mol% LiTFSI into a glass sample bottle, heat and stir at 60°C to dissolve. After obtaining a clear solution, add 3wt% FEC and stir well. Then, add PEO, stir to dissolve, the mass ratio of PEO and succinonitrile is 1:10. Finally, the obtained interface layer is subjected to vacuum defoaming treatment.

Embodiment 2

[0052] Add succinonitrile and 5mol% LiTFSI into a glass sample bottle, heat and stir at 60°C to dissolve. After obtaining a clear solution, add 7wt% FEC and stir well. Then, add PEO, stir to dissolve, the mass ratio of PEO and succinonitrile is 1:10. Finally, the obtained interface layer is subjected to vacuum defoaming treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com