Catalyst for catalyzing butyrolactone to obtain succinonitrile and synthesis method

A technology of succinonitrile and butyrolactone, which is applied in the field of nitrile synthesis and succinonitrile synthesis, can solve the problems of cumbersome preparation method, cumbersome reaction process, and high process cost, and achieve low production process requirements, high catalytic reaction efficiency, The effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] On the one hand, the present invention provides a kind of preparation method of succinonitrile, take gamma-butyrolactone as raw material, take supported catalyst as catalyzer, make described succinonitrile through ammoxidation reaction, specifically comprise: React with gas under the action of supported catalyst to obtain succinonitrile.

[0030] Wherein, the reaction raw material is γ-butyrolactone, and the gas includes ammonia and oxygen-containing gas.

[0031] Wherein, under the action of the supported catalyst, ammoxidation reaction occurs between γ-butyrolactone, ammonia and oxygen in oxygen-containing gas to prepare succinonitrile.

[0032] In the present invention, the ammonia gas provides a nitrogen source for the reaction, and the γ-butyrolactone reacts in the gas, the reaction raw material is single, and the generation of side reactions is avoided as much as possible.

[0033] The existing synthetic methods are mainly divided into hydrocyanic acid method, so...

Embodiment 1

[0100] (1) Preparation of supported catalyst

[0101] Dissolve 220g of oxalic acid in 760g of water to obtain an aqueous solution of oxalic acid, then dissolve 58g of vanadium pentoxide in the aqueous solution of oxalic acid, stir for 2 hours, and then add 18.2g of ammonium molybdate and 12.1g of boric acid to the above-mentioned stirred solution in sequence, and continue Stir for 2h; then, slowly add 92g of phosphoric acid solution, stir for 2h; finally, slowly add 10.6g of nickel chloride, 7.2g of cobalt acetate and 6.8g of sodium chloride, and stir for 2h to obtain a mixed solution, in which vanadium, phosphorus, The molar ratio of molybdenum, boron, sodium, cobalt and nickel elements is 1:1.25:0.15:0.31:0.18:0.1:0.07;

[0102] Add 1050g of silica sol with a concentration of 40wt% to the above mixed solution to obtain a catalyst slurry, heat and evaporate the catalyst slurry to a solid content of 45wt% in the catalyst slurry, then spray-dry it in a spray dryer to form, The...

Embodiment 2

[0113] (1) Preparation of supported catalyst

[0114] Catalyst is prepared in a manner similar to Example 1, difference is: 220g oxalic acid is dissolved in 760g water, obtains oxalic acid aqueous solution, then 58g vanadium pentoxide is dissolved in oxalic acid aqueous solution, stirs 2h, afterwards, to the mixing in above-mentioned stirring Add 18.2g of ammonium molybdate and 6.0g of boric acid in sequence, and continue to stir for 2 hours; then, slowly add 76g of phosphoric acid solution, stir for 2 hours, then slowly add 5.3g of nickel chloride, 7.2g of cobalt acetate and 6.8g of sodium chloride , stirred for 2h to obtain a mixed solution, the mol ratio of vanadium, phosphorus, molybdenum, boron, sodium, cobalt and nickel elements in the mixed solution is 1:1.03:0.15:0.15:0.18:0.10:0.04;

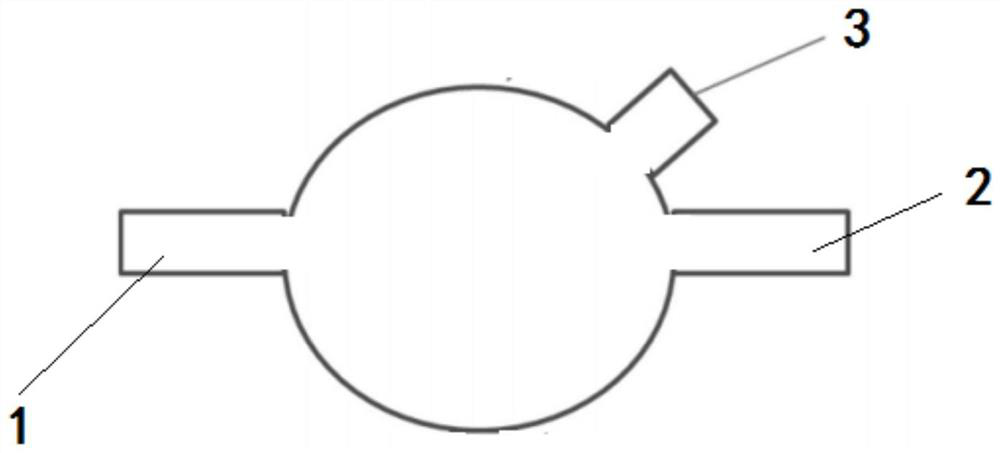

[0115] (2) Synthesis of Succinonitrile

[0116] 128g of the supported catalyst prepared above are dispersed on a fluidized bed with a diameter of 38mm and a height of 600mm in a glass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com