Nonaqueous electrolyte secondary battery

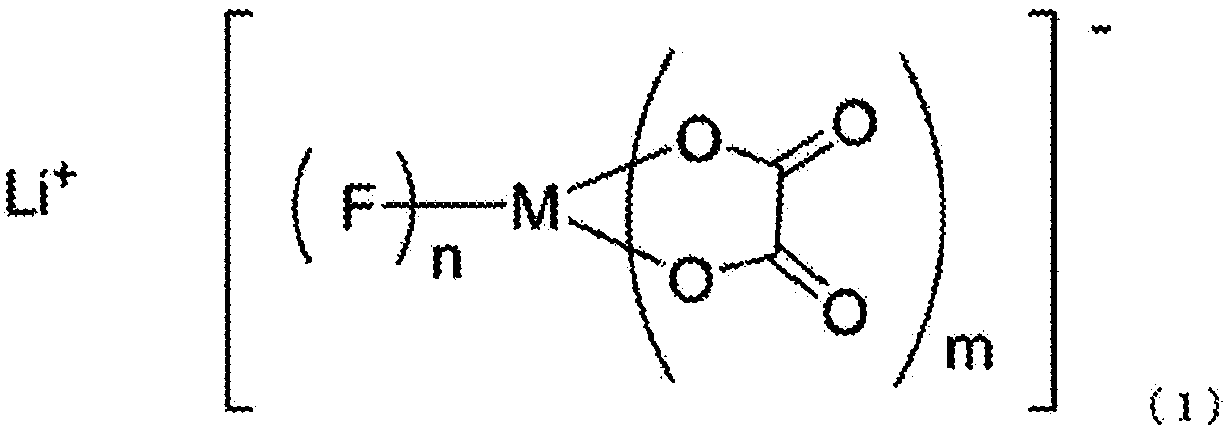

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolyte, secondary batteries, etc., can solve the problems affecting battery cycle performance, storage performance, charge and discharge efficiency, safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0158] Hereinafter, although an Example and a comparative example are used and it demonstrates in more detail, this invention is not limited at all by the following Example. In addition, unless otherwise stated, the following experiment was performed at 25 degreeC.

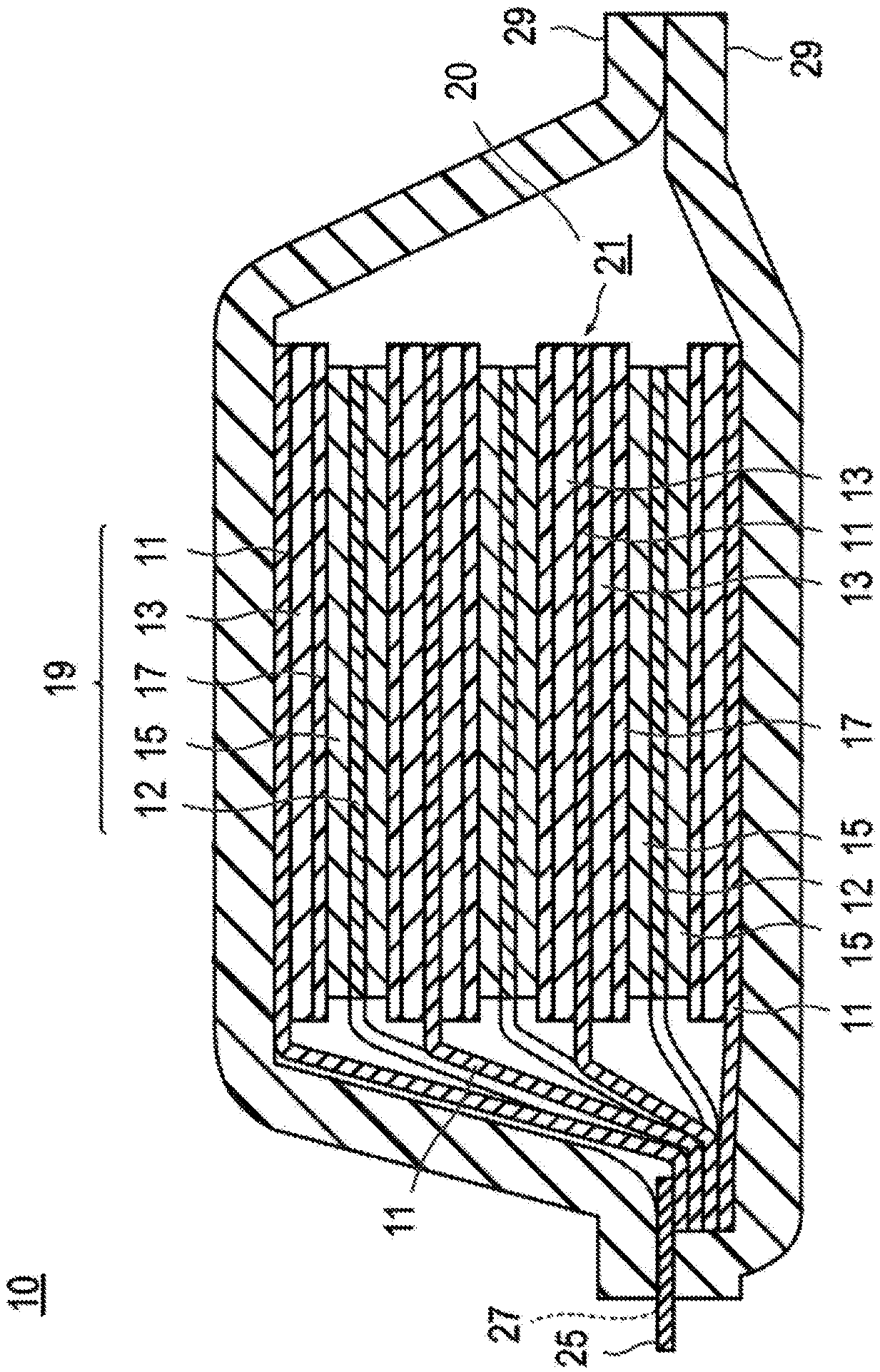

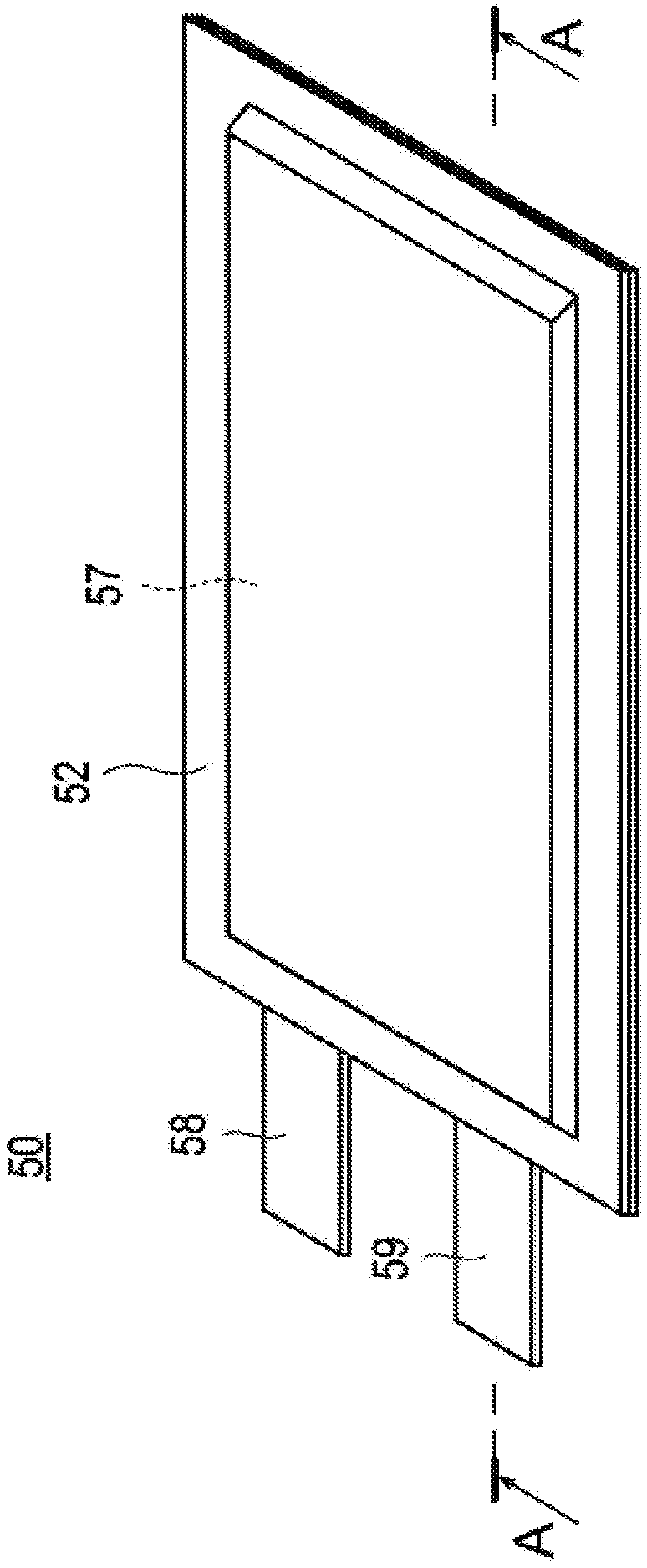

[0159] "Making of Laminated Batteries"

reference example 1

[0161] (1) Production of positive electrode

[0162] 95% by mass of NMC composite oxide (LiNi 0.5 mn 0.3 co 0.2 o 2 , average secondary particle size (D50) = 10 μm), 2% by mass of conductive carbon black (super-P) as a conductive additive, 3% by mass of polyvinylidene fluoride (PVdF) as a binder, and an appropriate amount N-methyl-2-pyrrolidone (NMP) used as a slurry viscosity adjusting solvent was mixed to prepare a positive electrode active material slurry.

[0163] The obtained positive electrode active material slurry was coated on both sides of an aluminum foil (thickness: 20 μm) as a positive electrode current collector, dried at 120° C. for 3 minutes, and then compression molded with a roll press to produce one side of the positive electrode active material layer. Coating amount (excluding current collector) is 18mg / cm 2 , The density of the positive electrode active material layer is 3.1g / cm 3 positive pole.

[0164] (3) Production of negative electrode

[0165...

reference example 2

[0174] As the negative electrode active material, natural graphite (with an amorphous coating layer on the surface, average particle size (D50) = 10 μm, BET specific surface area (SSA) = 3.5 m) was used instead. 2 / g), except that, the laminated battery of Reference Example 2 was produced by the same method as that of Reference Example 1 above. In addition, here, the negative electrode active material used is also called "active material (2)".

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com