Eutecticevaporate solvent based on non-proton organic matter and method for efficiently absorbing SO2 by utilizing same

A technology of deep eutectic solvent and sulfur dioxide, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of limited use, high production cost, cumbersome synthesis steps, etc., and achieve high absorption capacity and recycling effect Good and efficient reversible absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1, efficient capture of SO 2 Preparation of the deep eutectic solvent system

[0025] High-efficiency capture SO was prepared respectively by the following methods 2 The deep eutectic solvent system, specifically as follows:

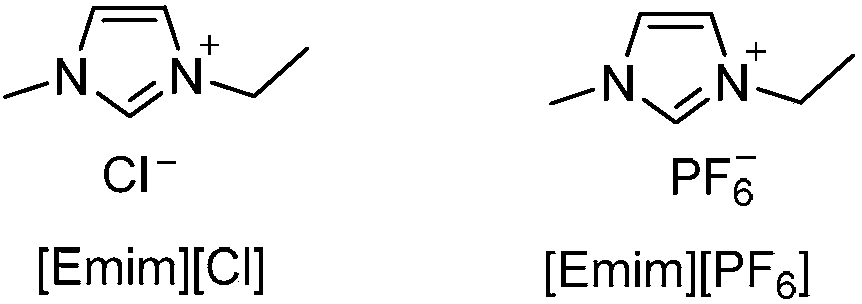

[0026] 1) Heat and stir 1-methyl-3-ethylimidazolium chloride and succinonitrile (SN) at 80°C in a molar ratio of 1:1 until the mixed system becomes liquid, then cool to room temperature , the deep eutectic solvent can be obtained, denoted as [Emim][Cl]-SN(1:1).

[0027] 2) Heat and stir 1-methyl-3-ethylimidazolium chloride salt and succinonitrile (SN) at 80°C in a molar ratio of 1:2 until the mixed system becomes liquid, then cool to room temperature , the deep eutectic solvent can be obtained, denoted as [Emim][Cl]-SN(1:2).

[0028] 3) Heat and stir 1-methyl-3-ethylimidazolium chloride salt and succinonitrile (SN) at 80°C according to the molar ratio of 1:4 until the mixed system becomes liquid, then cool to room temperature , the de...

Embodiment 2

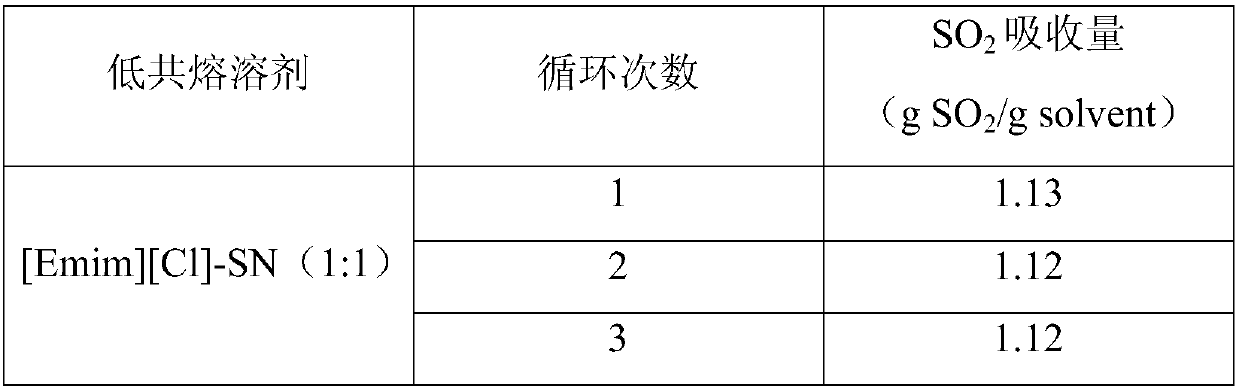

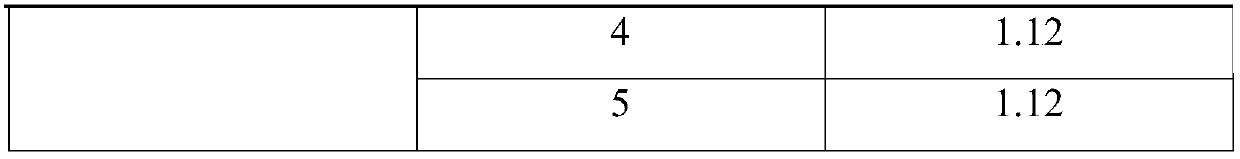

[0031] In a glass test tube with an inner diameter of 10 mm, add about 1.0 g of the deep eutectic solvent [Emim][Cl]-SN (1:1) prepared in Example 1 of the present invention, and then slowly introduce SO 2 Gas, the flow rate is 50mL / min, the absorption gas pressure is 0.1MPa, and the control temperature is 20°C. During the absorption process, it is weighed by an electronic analytical balance, and the mass of the glass test tube is weighed at intervals until there is no change. Calculated to absorb SO per gram of solvent 2 1.13 grams.

Embodiment 3

[0033] In a glass test tube with an inner diameter of 10 mm, add about 1.0 g of the deep eutectic solvent [Emim][Cl]-SN (1:2) prepared in Example 1 of the present invention, and then slowly introduce SO 2 Gas, the flow rate is 50mL / min, the absorption gas pressure is 0.1MPa, and the control temperature is 20°C. During the absorption process, it is weighed by an electronic analytical balance, and the mass of the glass test tube is weighed at intervals until there is no change. Calculated to absorb SO per gram of solvent 2 0.96 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com