Electrolyte for 4.5 V lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low charging and discharging efficiency of lithium-ion batteries, poor cycle performance, and restrictions on the development of high-voltage lithium-ion batteries, and achieve improvement High-pressure cycle performance, not easy to decompose, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

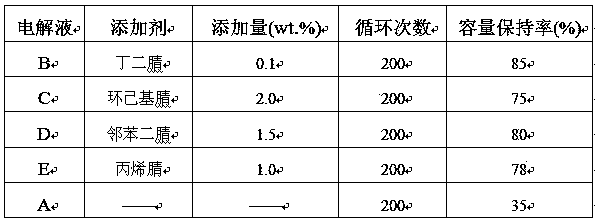

[0012] Lithium-ion battery electrolyte that is not easy to decompose under 4.5V high voltage, including a nitrile compound, which is succinonitrile, when the high-voltage additive is used in the lithium-ion battery electrolyte, the mass percentage of the electrolyte 0.1%. The organic solvent in the electrolyte is a mixture of ethylene carbonate (EC), dimethyl carbonate (DMC) and ethyl methyl carbonate (EMC), where the mass ratio of EC, DMC and EMC is 40%:40%:20% . The electrolytes of Li-ion batteries were 1.0 M LiPF 6 It is denoted as electrolyte B, and the electrolyte without additives is denoted as A.

[0013] Inject A and B electrolytes into the positive electrode LiCoPO 4 , In an aluminum case lithium-ion battery with an artificial graphite as the negative electrode (nominal capacity is 650Ah), a 0.5C charge-discharge cycle is performed within the voltage range of 3.0~4.5V. The capacity retention rate of the battery using A electrolyte is about 35% after 200 cycles, w...

Embodiment 2

[0015] The lithium-ion battery electrolyte that is not easy to decompose under a high voltage of 4.5V contains a nitrile compound, which is cyclohexyl nitrile. When the high-voltage additive is used in the lithium-ion battery electrolyte, the proportion of The mass percentage is 2.0%. The organic solvent in the electrolyte is a mixture of ethylene carbonate (EC), dimethyl carbonate (DMC) and ethyl methyl carbonate (EMC), where the mass ratio of EC, DMC and EMC is 40%:40%:20% . The electrolyte of Li-ion batteries is 1.0 M LiPF 6 Denoted as electrolyte C.

[0016] Inject the C electrolyte into the cathode LiCoPO 4 , In an aluminum case lithium-ion battery with an artificial graphite negative pole (nominal capacity is 650Ah), a 1C charge-discharge cycle is performed within the voltage range of 3.0~4.5V. After 200 cycles of electrolyte battery cycle, the battery capacity retention rate reaches more than 75%.

Embodiment 3

[0018] The lithium-ion battery electrolyte that is not easily decomposed under a high voltage of 4.5V contains a nitrile compound, which is phthalonitrile. When the high-voltage additive is used in the lithium-ion battery electrolyte, the The mass percentage accounted for is 1.5%. The organic solvent in the electrolyte is a mixture of ethylene carbonate (EC), dimethyl carbonate (DMC) and ethyl methyl carbonate (EMC), where the mass ratio of EC, DMC and EMC is 40%:40%:20% . The electrolyte of Li-ion batteries is 1.0 M LiPF 6 Denoted as electrolyte D.

[0019] Inject the D electrolyte into the positive electrode LiCoPO 4 , in an aluminum case lithium-ion battery with artificial graphite as the negative electrode (nominal capacity is 650Ah), 1C charge-discharge cycle is performed in the voltage range of 3.0~4.5V, and the battery capacity retention rate of the battery after 200 cycles of the electrolyte reaches more than 80%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com