Electrolyte for improving performance of lithium ion battery, preparation method of electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as the harmful effect of decomposition products on battery performance, the problem of gas production from decomposition products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing an electrolyte for improving lithium battery performance, comprising the following steps:

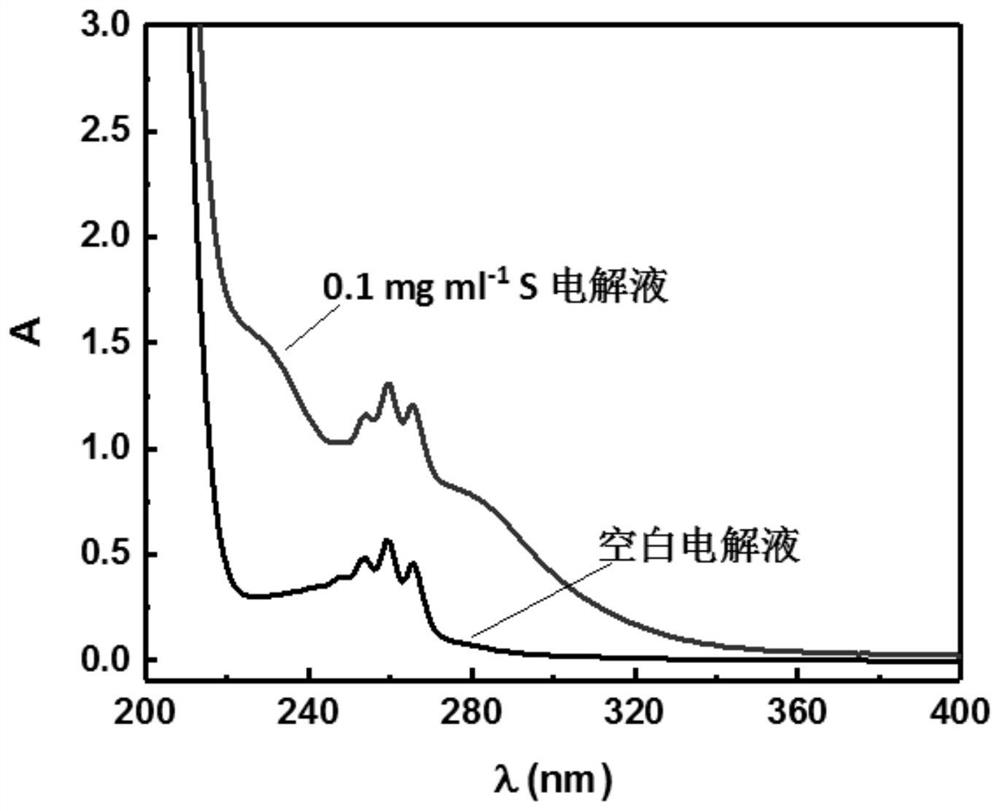

[0031] A) adding the additive into the organic solvent, stirring and heating until the additive is completely dissolved to obtain an additive solution; the additive is simple sulfur; the mass concentration of the additive is 0.1-2 mg / mL;

[0032] B) After lithium salt is added to the additive solution, an electrolyte solution for improving the performance of the lithium-ion battery is obtained.

[0033] In the present invention, it is preferred to firstly mix the cyclic carbonate and the chain carbonate under a protective gas atmosphere to obtain an organic solvent.

[0034] The types and amounts of the cyclic carbonates and chain carbonates are the same as those described above, and will not be repeated here.

[0035] In the present invention, the protective gas is preferably an inert gas, more preferably high-purity ar...

Embodiment 1-5

[0045] A preparation method of an electrolyte for improving lithium-ion battery performance, comprising the following steps:

[0046] The first step: in a room temperature environment filled with high-purity argon, add 10ml of ethylene carbonate and dimethyl carbonate with a volume ratio of 3:7 into the sample bottle to form a mixed solution;

[0047] The second step: adding elemental sulfur as an additive to the mixed solution of the first step, stirring the solution with the additive, and heating at 80°C until the elemental sulfur is completely dissolved;

[0048] The third step: dissolving 1M lithium hexafluorophosphate in the mixed solution of the second step.

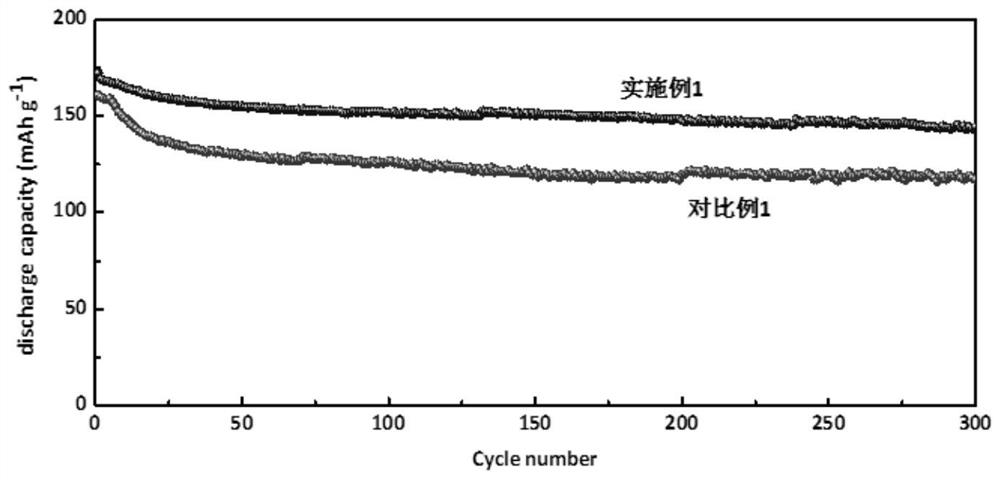

[0049] Considering the influence of the content of elemental sulfur on the performance of lithium-ion batteries, under the condition that other conditions remain unchanged, only by changing the content of elemental sulfur to carry out the transformation of the embodiment, and investigating the effect of electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com