PVDF-based composite solid electrolyte and preparation method thereof

A solid electrolyte and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of poor interface contact, difficult mass production and processing, low ionic conductivity, etc., to increase ionic conductivity, suitable for Large-scale production, the effect of high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

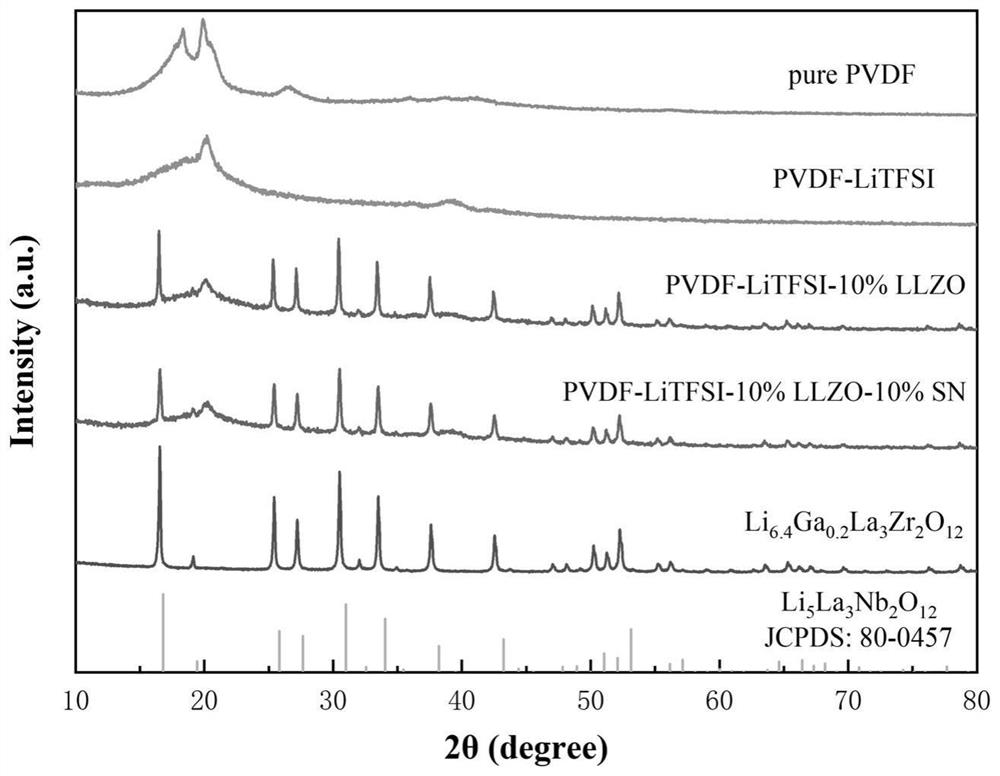

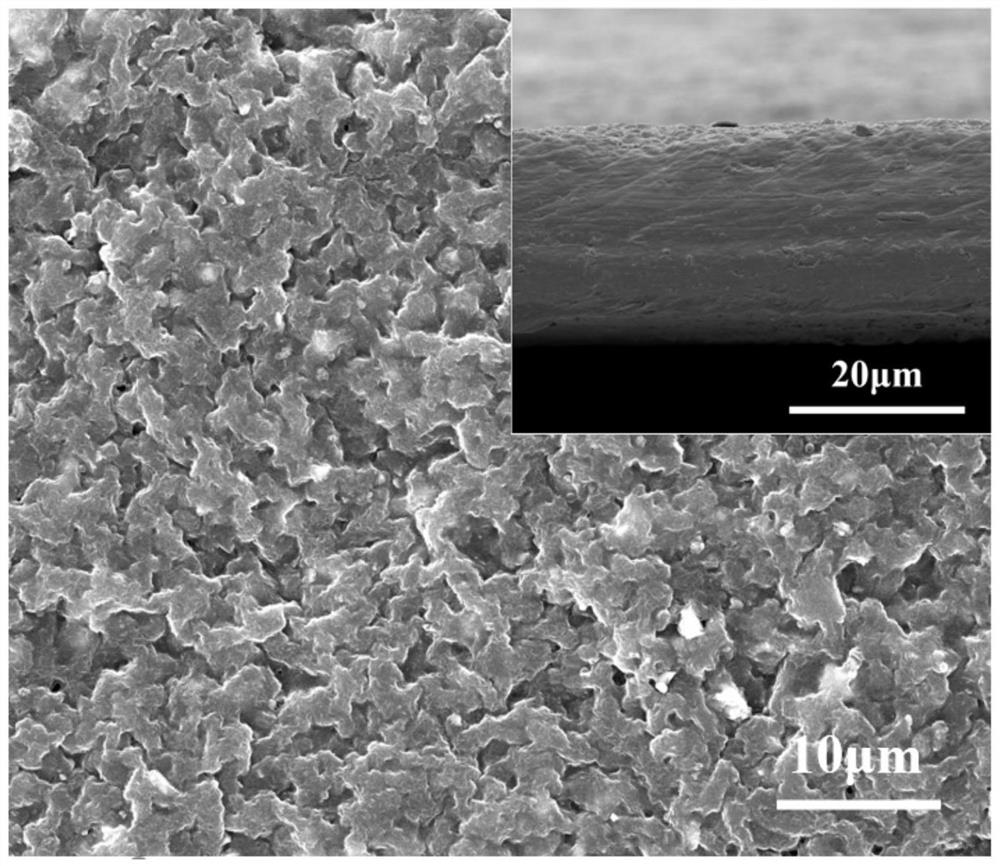

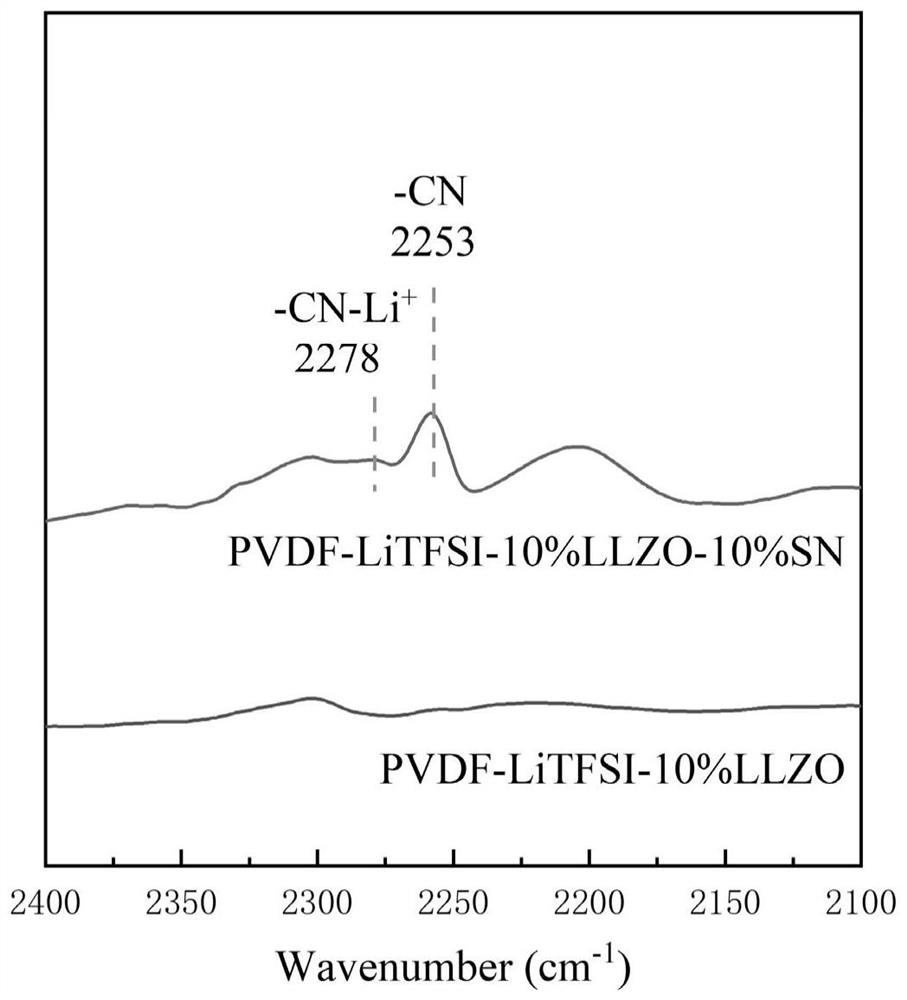

[0025] Accurately weigh 0.239g LiTFSI and 0.0789g SN in the glove box, then dissolve them together in 15mL N,N-dimethylformamide (DMF), stir the resulting mixture at room temperature until completely dissolved, then add 0.4g PVDF and Continue to stir until completely dissolved to obtain a homogeneous and transparent composite solution. Accurately weigh 0.071g Li 6.4 Ga 0.2 La 3 Zr 2 o 12 Powder, which is added to the aforementioned composite solution, ultrasonically dispersed and then stirred for 24 hours to obtain a uniform composite slurry. The composite slurry was poured on a polytetrafluoroethylene plate, and then vacuum-dried at 60°C for 48 hours to remove the solvent, and finally the desired composite solid electrolyte membrane was obtained, denoted as PVDF-LiTFSI-10%LLZO-10%SN.

[0026] In order to further understand the performance of the composite solid electrolyte membrane, it is processed into the required shape, and it is stacked with the positive and negative...

Embodiment 2

[0028] Accurately weigh 0.117g LiFSI and 0.034g SN in the glove box, then dissolve them together in 12mL N-methylpyrrolidone (NMP), stir the resulting mixture at 50°C until completely dissolved, then add 0.4g PVDF and continue stirring until Completely dissolved to obtain a homogeneous and transparent compound solution. Accurately weigh 0.129g of LLZO powder, add it to the aforementioned composite solution, and stir for 12 hours after ultrasonic dispersion to obtain a uniform composite slurry. The composite slurry was poured on a polytetrafluoroethylene plate, and then vacuum-dried at 80°C for 24 hours to remove the solvent, and finally the desired composite solid electrolyte membrane was obtained, denoted as PVDF-LiFSI-20%LLZO-5%SN.

[0029]The composite solid electrolyte membrane is processed into the desired shape, stacked and pressed together with the positive and negative electrodes in the glove box, and finally sealed in a button battery or aluminum-plastic composite pac...

Embodiment 3

[0031] Accurately weigh 0.1g LiBOB and 0.152g SN in the glove box, then dissolve them together in 15mL dimethyl sulfoxide (DMSO), stir the resulting mixture at 60°C until completely dissolved, then add 0.5g PVDF and continue stirring until Completely dissolved to obtain a homogeneous and transparent compound solution. Accurately weigh 0.258g of LLZO powder, add it to the aforementioned composite solution, and stir for 10 hours after ultrasonic dispersion to obtain a uniform composite slurry. The composite slurry was poured on a polytetrafluoroethylene plate, and then vacuum-dried at 70°C for 36 hours to remove the solvent, and finally the desired composite solid electrolyte membrane was obtained, denoted as PVDF-LiBOB-30%LLZO-15%SN.

[0032] The composite solid electrolyte membrane is processed into the desired shape, stacked and pressed together with the positive and negative electrodes in the glove box, and finally sealed in a button battery or aluminum-plastic composite pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com