Lithium ion battery and preparation method

A technology of lithium ion batteries and lithium salts, which is applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc. problems, to achieve the effect of long service life, high safety and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

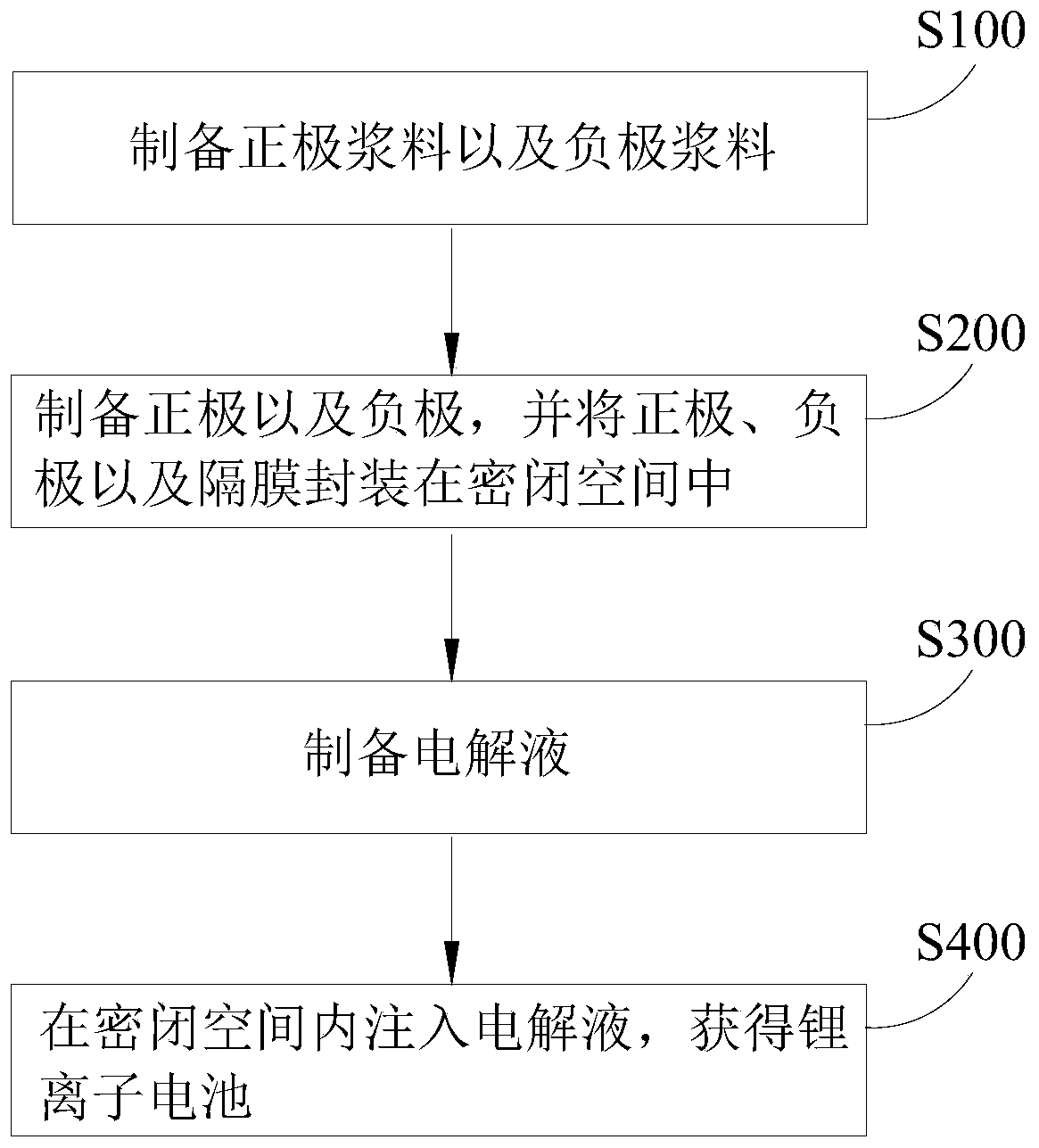

Method used

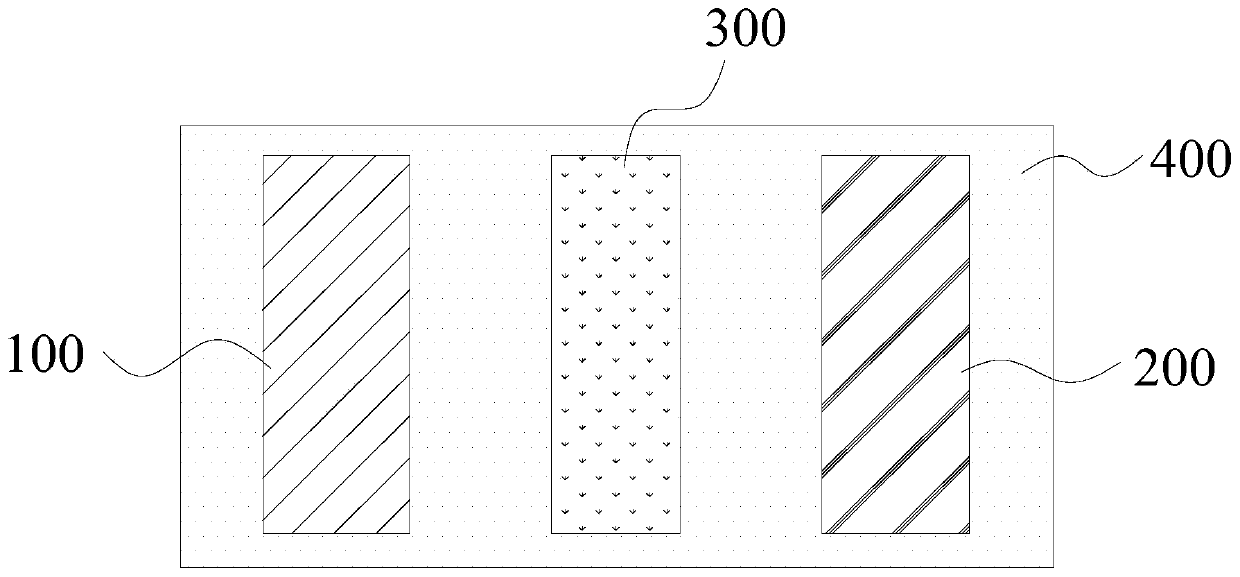

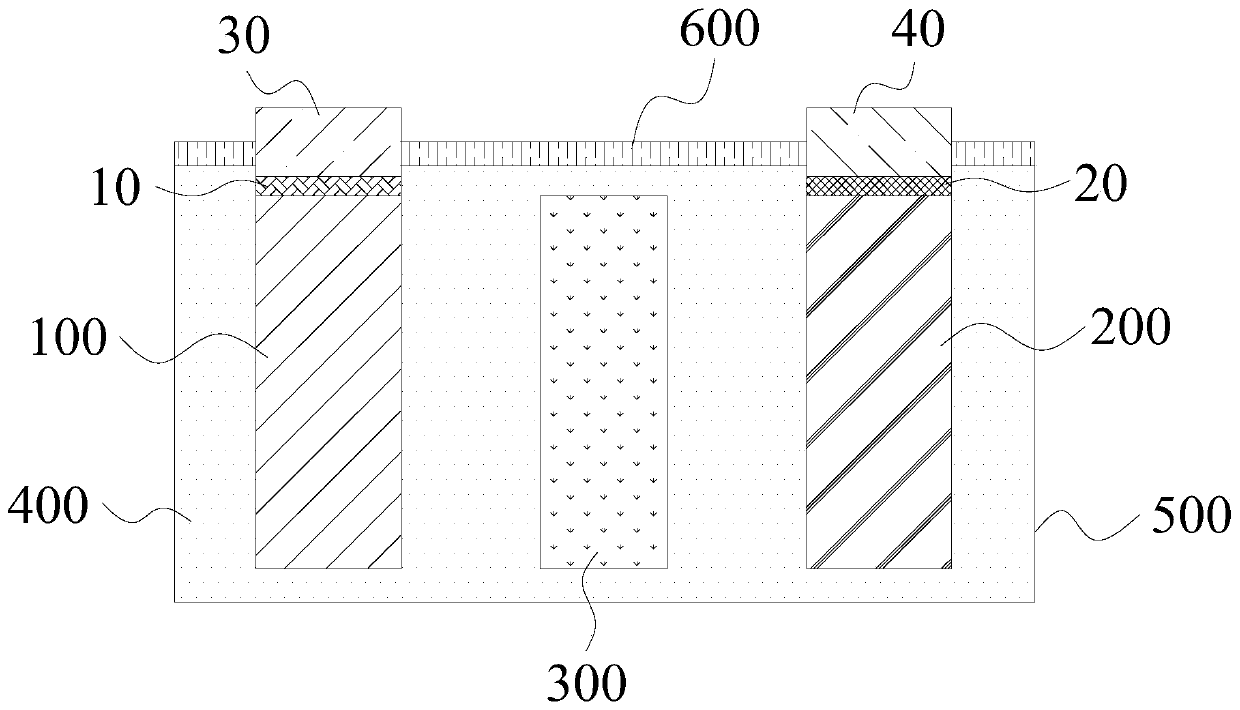

Image

Examples

Embodiment 1

[0072] The lithium ion battery includes: a positive pole, a negative pole, a diaphragm, an electrolyte, a casing and a cover plate. Wherein, the positive electrode includes: a positive electrode active material, a conductive agent, a binder and an aluminum foil, and the thickness of the aluminum foil is 12 μm. The positive electrode active material is a nickel-cobalt-manganese ternary material with a percentage of nickel being 50%, the conductive agent is conductive carbon black and carbon nanotubes, and the binder is polyvinylidene fluoride. The mass percentages of positive electrode active material, conductive agent and binder in the positive electrode are respectively: the mass percentage of nickel-cobalt-manganese ternary material is 96%, the mass percentage of polyvinylidene fluoride is 2%, and the mass percentage of conductive carbon black is 1.5% %, the mass percentage of carbon nanotubes is 0.5%.

[0073] The negative electrode includes: negative electrode active mate...

Embodiment 2

[0087] The lithium ion battery of this embodiment is the same as that of Embodiment 1, except that the percentage of nickel in the nickel-cobalt-manganese ternary material is 53%.

Embodiment 3

[0089]The lithium ion battery of this embodiment is the same as that of Embodiment 1, except that the degree of graphitization of graphite is 92.5%, and the OI value is 6.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com