Carton sealing machine

A carton sealing machine and carton technology, applied in packaging sealing/fastening, external support, transportation and packaging, etc., can solve the problems of inability to process and package different types of cartons continuously, slow speed, increased machine footprint and processing costs, etc. , to achieve rapid and continuous production and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, invention is described in further detail.

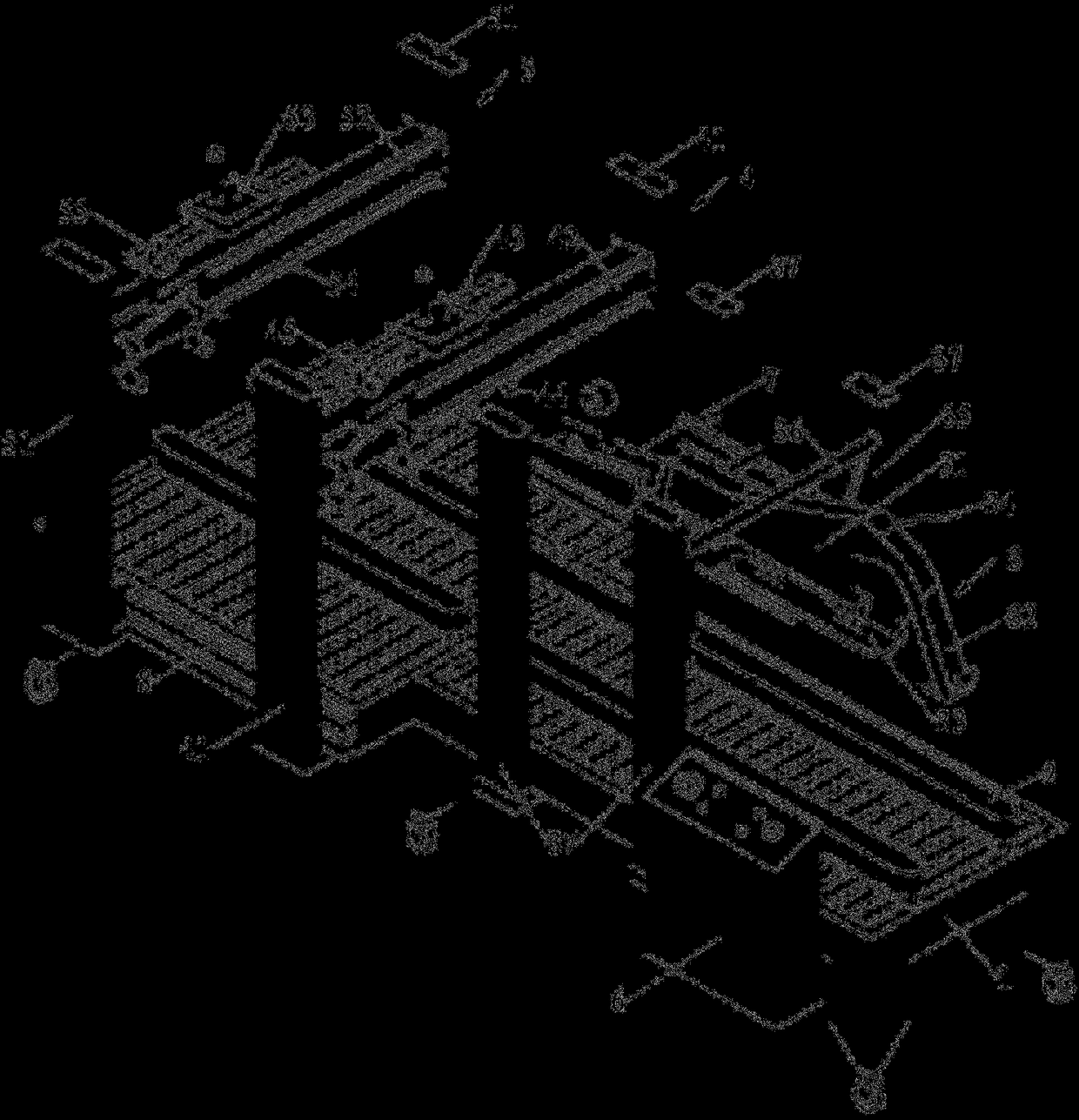

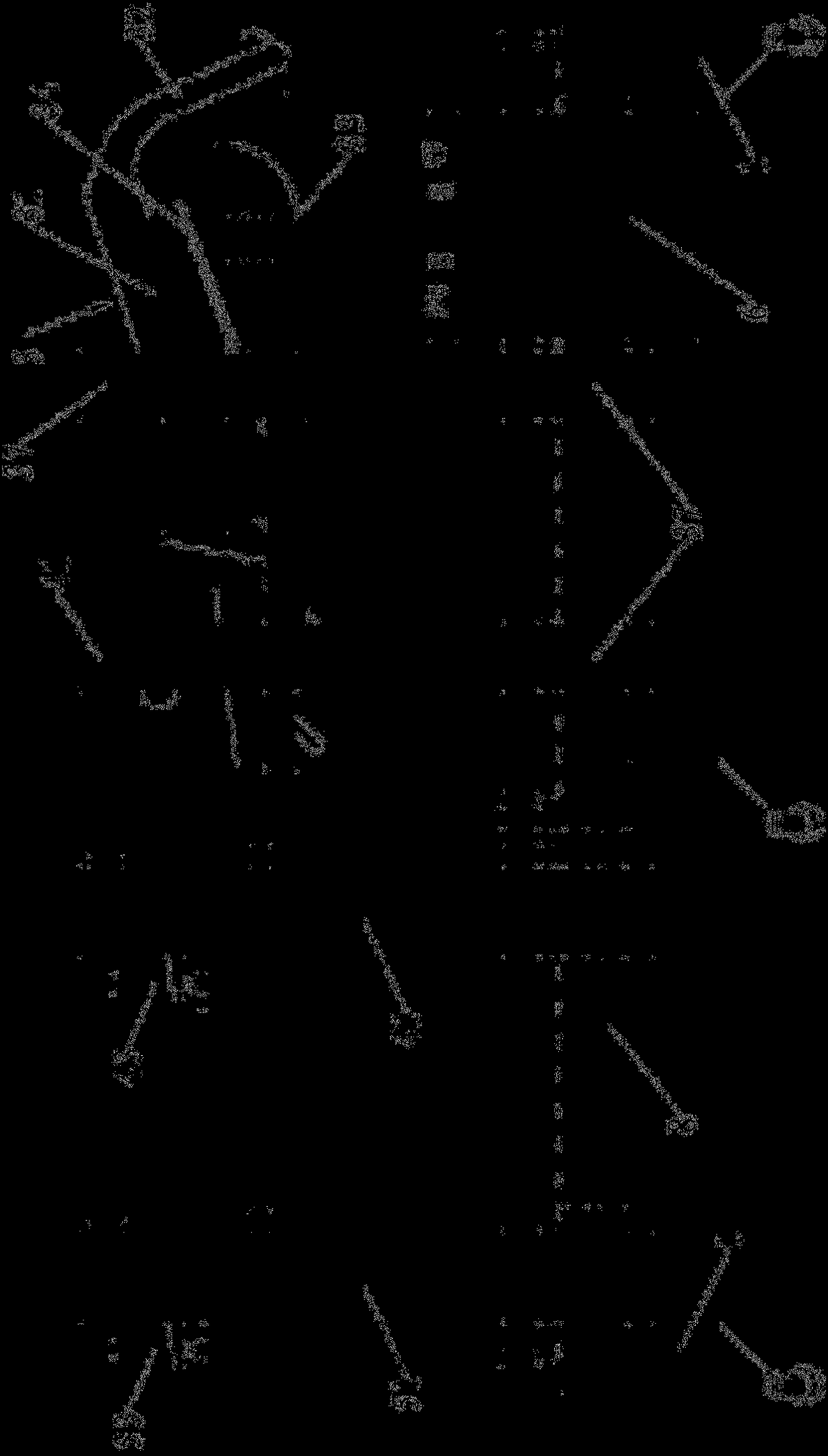

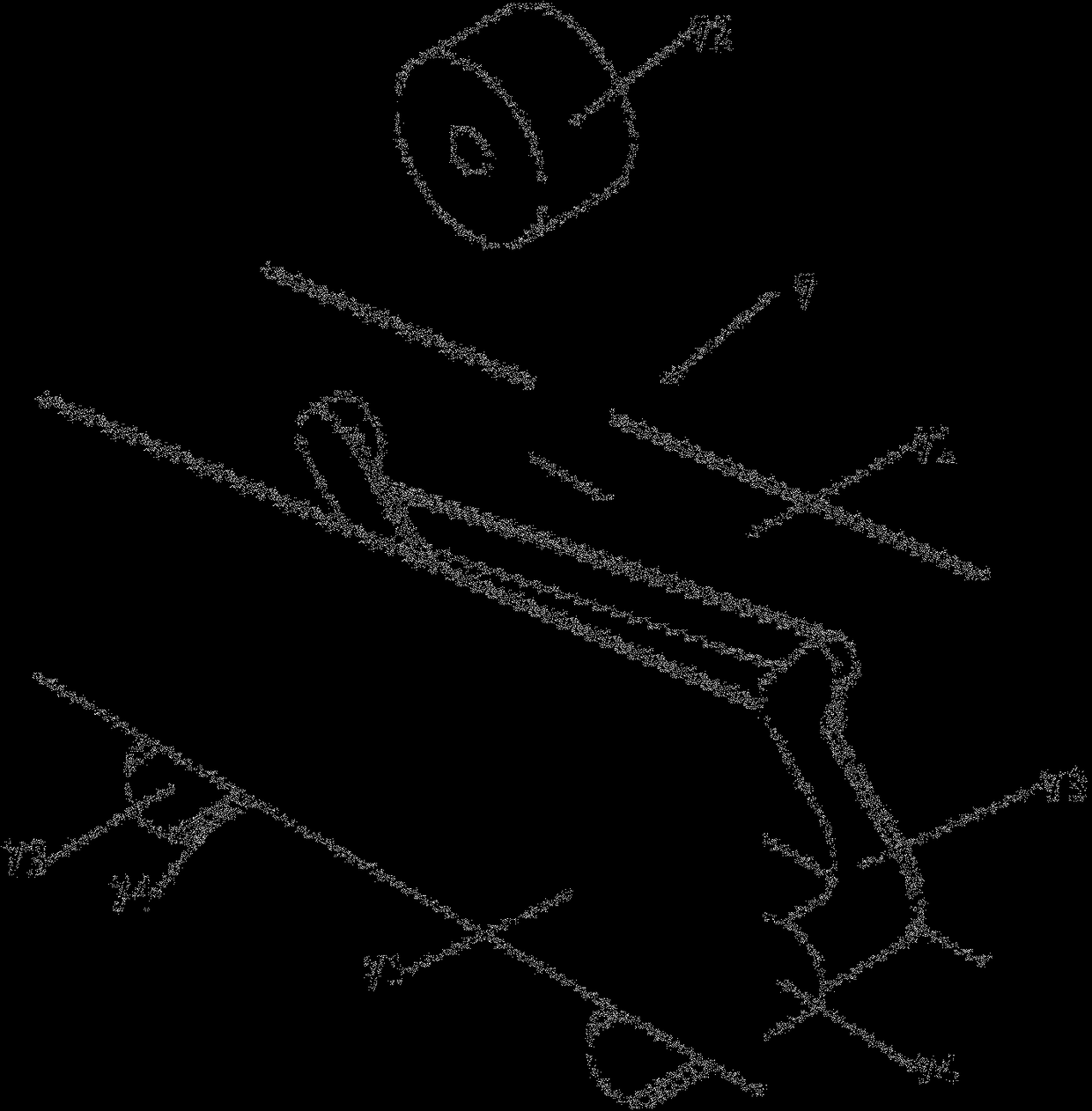

[0018] Figure 1 ~ Figure 4 A carton sealing machine according to an embodiment of the present invention is schematically shown.

[0019] refer to Figure 1 ~ Figure 4 The carton sealing machine includes a frame 1, a conveying device 2, a lid closing device 3, a first side seam sealing device 4, a second side seam sealing device 5 and a control device 6, a middle seam sealing device 7 and a lifting column Adjust rail 8.

[0020] The lid closing device 3 , the first side seam sealing device 4 and the second side seam sealing device 5 are arranged in sequence and are all mounted on the frame 1 . The conveying device 2 is fixed on the frame 1, and the conveying device 2 is located below the lid closing device 3, the first side seam sealing device 4 and the second side seam sealing device 5. The conveying device 2, the lid closing device 3, the first side seam sealing device 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com