Glycyrrhizic acid-based slow-release porous foam material capable of embedding hydrophilic functional factors and preparation method and application thereof

A technology of porous foam materials and functional factors, which can be applied to medical preparations without active ingredients, medical preparations containing active ingredients, pharmaceutical formulas, etc., and can solve the problems of poor stability, easy scattering, and difficulty in molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In terms of mass fraction, 4 parts of glycyrrhizic acid were uniformly dispersed in 4 parts of deionized water, heated and stirred at 80° C. to obtain a transparent glycyrrhizic acid solution with a concentration of 4 wt%.

[0044] In terms of mass fraction, 4 parts of hydroxyethyl cellulose with different masses were uniformly dispersed in deionized water, heated and stirred at 80°C to obtain transparent hydroxyethyl cellulose with concentrations of 1wt%, 4wt%, and 8wt%, respectively. solution.

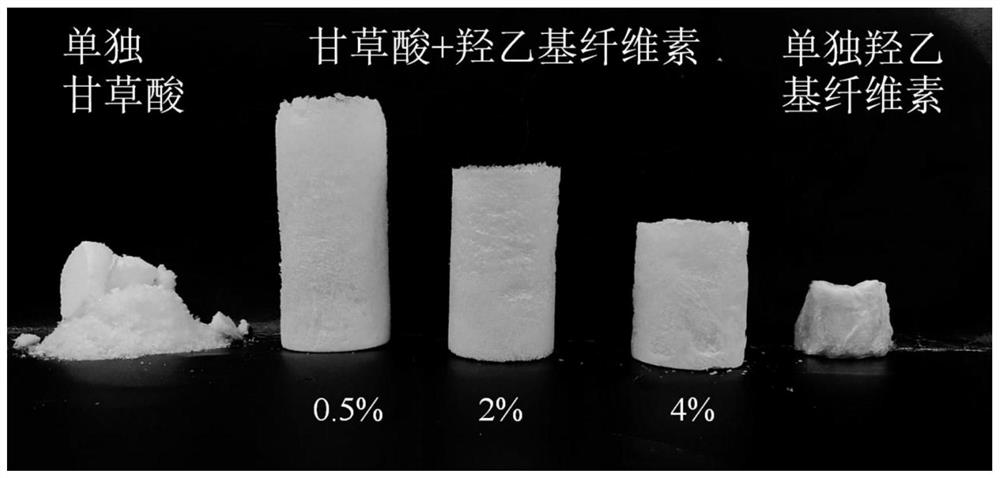

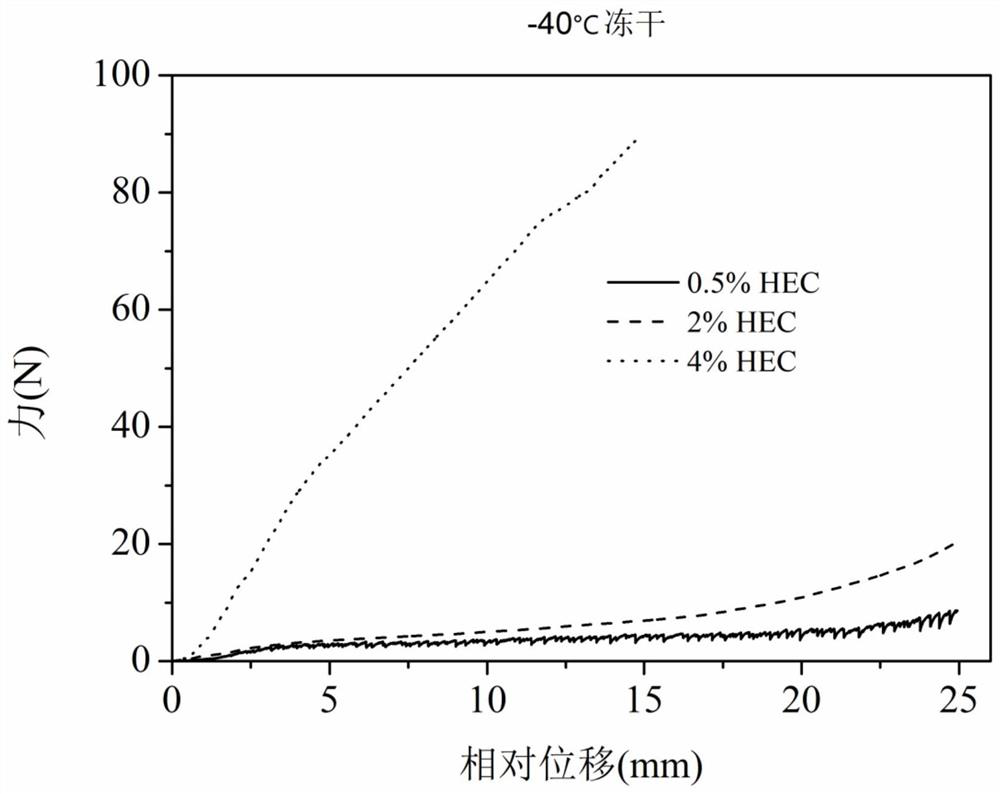

[0045] Add 3 parts of hydroxyethyl cellulose transparent solutions of different concentrations to 3 parts of glycyrrhizic acid solutions with the same concentration respectively, and control the final concentration of hydroxyethyl cellulose to be 0.5wt%, 2wt%, 4wt% respectively; at 80 °C in a water bath with stirring.

[0046] The remaining 1 part of glycyrrhizic acid solution and the remaining hydroxyethyl cellulose solution were used as a blank control, heated and stirred i...

Embodiment 2

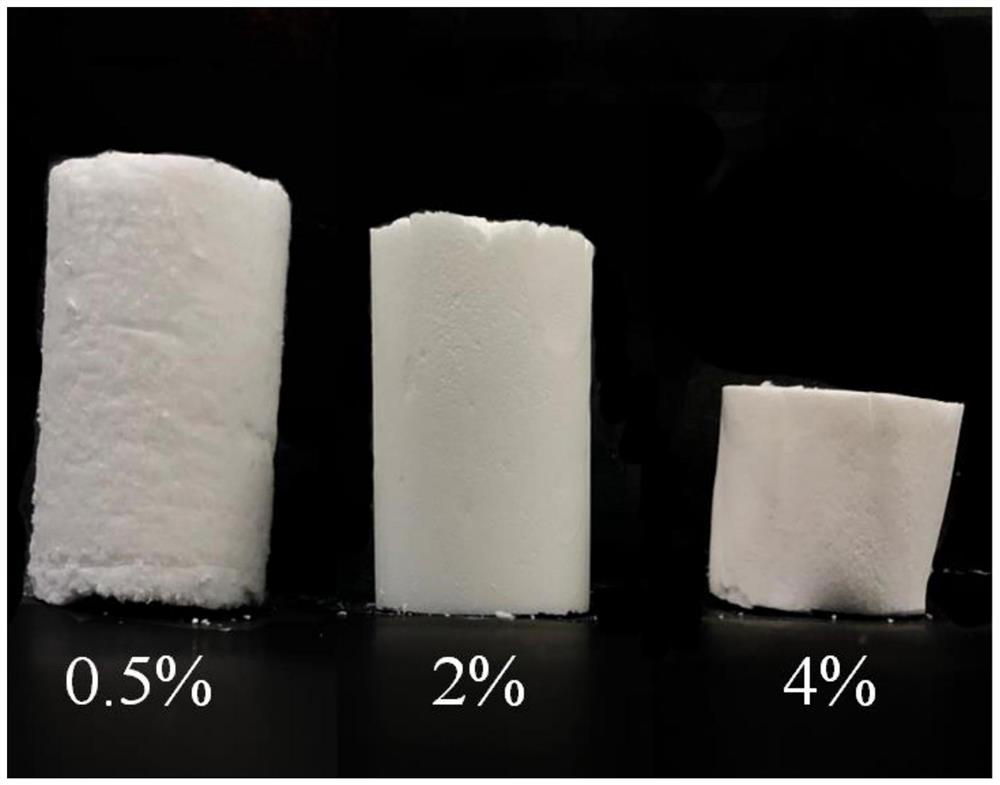

[0053] In terms of mass fraction, 3 parts of glycyrrhizic acid were uniformly dispersed in deionized water, heated and stirred at 80° C. to obtain a transparent glycyrrhizic acid solution with a concentration of 4 wt%. Three parts of hydroxyethyl cellulose with different masses were uniformly dispersed in deionized water respectively, heated and stirred at 80°C to obtain transparent solutions with different concentrations. Add 3 parts of hydroxyethyl cellulose solutions of different concentrations to 3 parts of glycyrrhizic acid solutions with the same concentration, control the final concentration of hydroxyethyl cellulose to 0.5wt%, 2wt%, 4wt%, heat in a water bath at 80°C and Stir. Homogenize the mixed solution for 2min at a speed of 20000rpm. The foam gel was obtained by placing it in an ice-water bath, and the foam gel was placed in liquid nitrogen for 5 minutes and then freeze-dried to obtain a porous foam material.

[0054] In embodiment 2, image 3 It is the appeara...

Embodiment 3

[0057] In terms of mass fraction, 3 parts of glycyrrhizic acid were uniformly dispersed in deionized water, heated and stirred at 80° C. to obtain a transparent glycyrrhizic acid solution with a concentration of 4 wt%.

[0058] A certain amount of riboflavin sodium phosphate was added to 3 parts of glycyrrhizic acid solution, heated and stirred at 80° C. to obtain a yellow mixed solution containing 20% riboflavin sodium phosphate.

[0059] In terms of mass fraction, 3 parts of hydroxyethyl cellulose with different masses were uniformly dispersed in deionized water, heated and stirred at 80°C to obtain transparent solutions with concentrations of 1 wt%, 4 wt%, and 8 wt%.

[0060] Add 3 parts of hydroxyethyl cellulose solutions of different concentrations to 3 parts of glycyrrhizic acid solutions loaded with riboflavin sodium phosphate respectively, and control the final concentration of hydroxyethyl cellulose to 0.5wt%, 2wt%, 4wt%, Heat and stir in a water bath at 80°C. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com