Method for preparing methyl methacrylate by using methacrolein

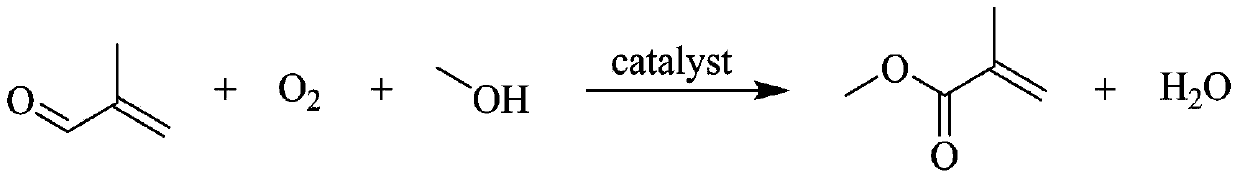

A technology of methyl methacrylate and methacrolein, applied in the field of preparation of methyl methacrylate, can solve the problems of unfavorable reaction in the positive direction, reducing the total yield of the process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

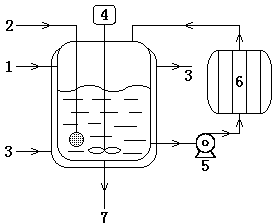

Image

Examples

Embodiment 1

[0015] 25 g PdCl 2 Stir and dissolve in 100 mL of 20% nitric acid aqueous solution, then add 15 g of magnesium oxide carrier, stir and impregnate for 30 min, filter, wash with water, and vacuum dry to obtain the catalyst.

Embodiment 2

[0017] The external circulation water removal system in this embodiment is a single water removal column filled with water removal agent, the size of the water removal column is 1 m×0.12 m inner diameter, and the filling rate of water removal agent is 75%.

[0018] The qualitative and quantitative detection methods of reaction substrates and products are as follows: using SE-30 (30 m×0.25 mm×0.5 μm) quartz capillary column, the temperature of the vaporization chamber is 115 °C; the temperature of the column is 105 °C; the temperature of the FID detector is 280 °C; the carrier gas: High purity N 2 ; Column flow rate: 0.6 mL / min; Split ratio: 40:1.

[0019] Pump the mixture of 70.09 g (1 mol) methacrolein and 192.24 g (6 mol) methanol into the reaction kettle, heat it to the reaction temperature of 50 °C, and carry out the oxidative esterification reaction under the action of the catalyst palladium composite oxide, the reaction During the process, the reaction mixture was fed a...

Embodiment 3

[0021] The external circulation water removal system of this embodiment is a combination of two water removal columns filled with water removal agents connected in series, where each water removal column has a size of 0.8 m x an inner diameter of 0.12 m, and the filling rate of water removal agents is 80%.

[0022] Reaction substrate and product qualitative and quantitative detection method and operation are all the same as in Example 2, and the implementation steps of changing catalyst dewatering agent and each operating parameter are as follows:

[0023] Pump the mixture of 70.09 g (1 mol) methacrolein and 128.16 g (4 mol) methanol into the reaction kettle, heat it to the reaction temperature of 60 °C, and carry out the oxidative esterification reaction under the action of the catalyst palladium composite oxide, the reaction During the process, the reaction mixture was fed at a certain flow rate into the external circulation water removal system 6 filled with anhydrous calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com