Rare Earth Magnet and Method for Manufacturing Same

a technology manufacturing methods, applied in the field of rare earth magnets, can solve the problems of relatively low corrosion resistance of these magnets, and achieve the effect of sufficient corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

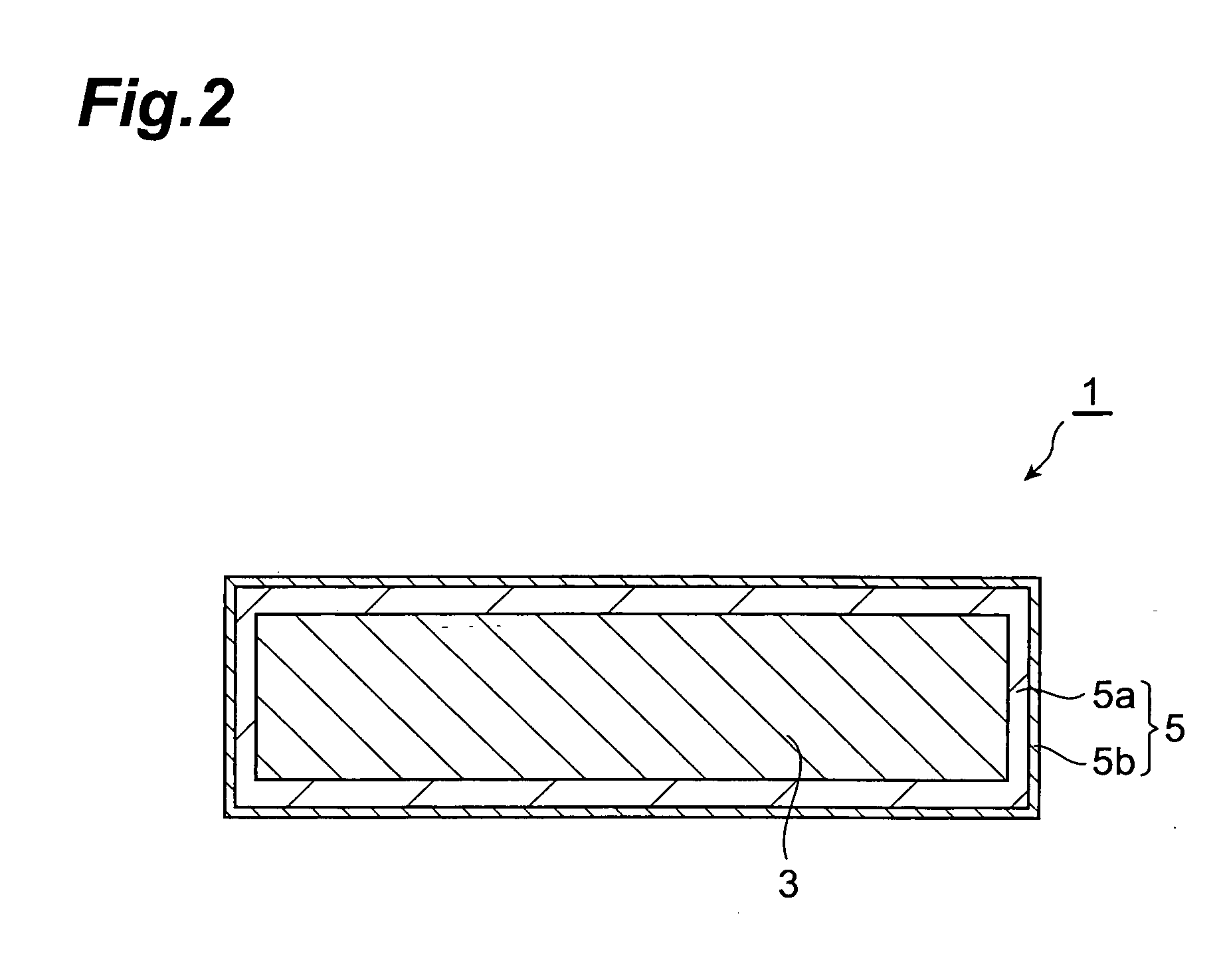

[0084]To begin with, a first embodiment of the rare-earth magnet and method of manufacturing the same in accordance with the present invention will be explained. The rare-earth magnet of the first embodiment comprises a magnet body containing a rare-earth element, and a protective layer formed on a surface of the magnet body, whereas the protective layer includes a first layer covering the magnet body and containing a rare-earth element, and a second layer covering the first layer and containing substantially no rare-earth element.

[0085]FIG. 1 is a schematic perspective view showing the rare-earth magnet in accordance with the first embodiment. FIG. 2 is a view schematically showing a cross-sectional structure appearing when the rare-earth magnet shown in FIG. 1 is cut along the line II-II. As shown in FIGS. 1 and 2, the rare-earth magnet 1 of this embodiment is constructed by a magnet body 3 and a protective layer 5 formed so as to cover all the surfaces of the magnet body 3.

[0086]...

second embodiment

[0120]A second embodiment of the rare-earth magnet and method of manufacturing the same in accordance with the present invention will now be explained. The rare-earth magnet of the second embodiment comprises a magnet body containing a rare-earth element, and a protective layer formed on a surface of the magnet body, whereas the protective layer includes an inner protective layer containing a rare-earth element and / or a transition element and oxygen, and an outer protective layer made of a constituent material different from that of the inner protective layer. In the rare-earth magnet of the second embodiment, the inner protective layer has a structure comprising a first layer covering the magnet body and containing a rare-earth element, and a second layer covering the first layer and containing substantially no rare-earth element.

[0121]FIG. 3 is a schematic perspective view showing the rare-earth magnet in accordance with the second embodiment. FIG. 4 is a view schematically showin...

examples

[0213]In the following, the present invention will be explained in further detail with reference to Examples, which do not restrict the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com