Process for producing magnet

一种制造方法、磁铁的技术,应用在磁铁的制造领域,能够解决Br降低、饱和磁化强度变小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

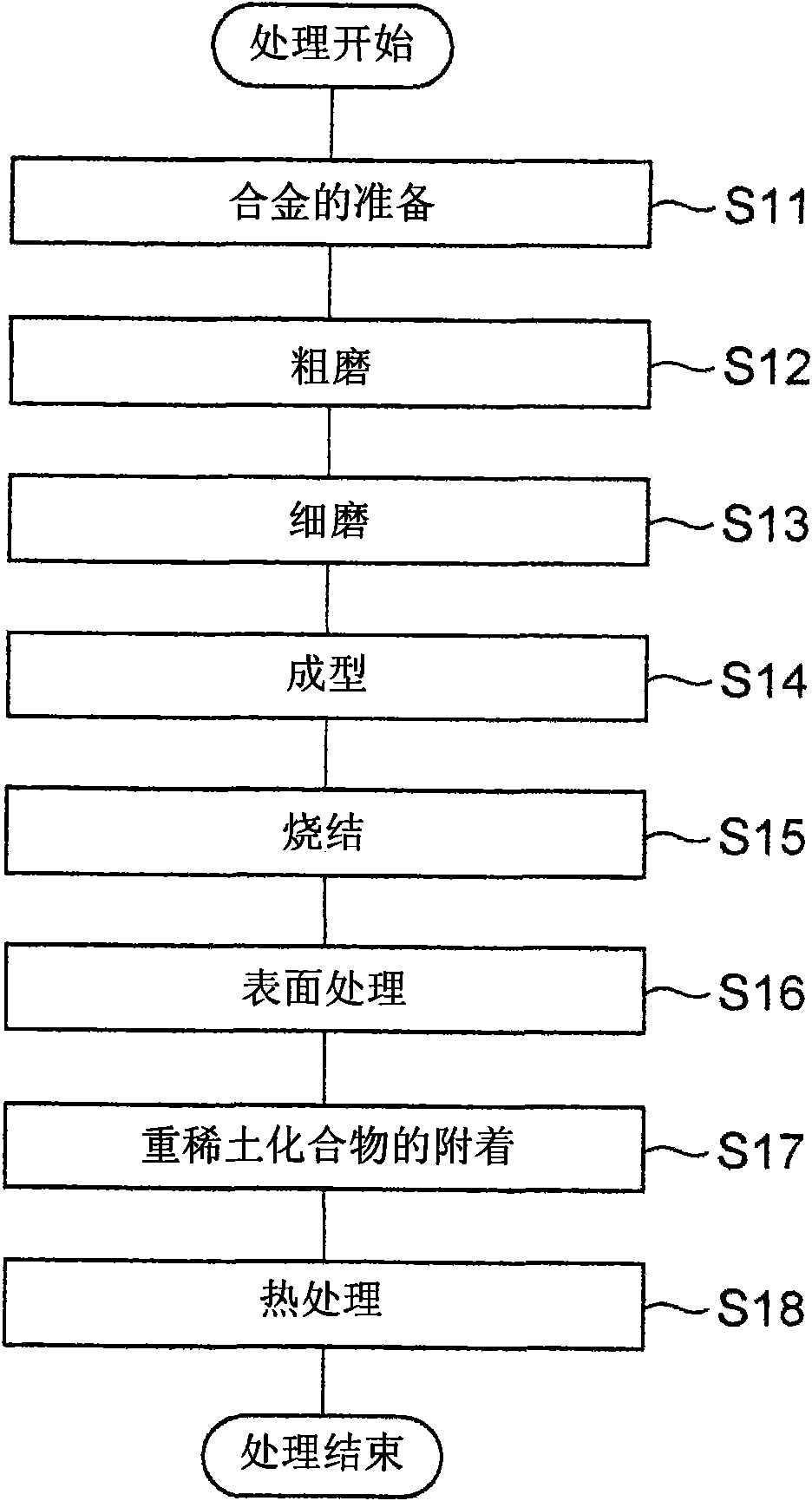

Method used

Image

Examples

Embodiment 1

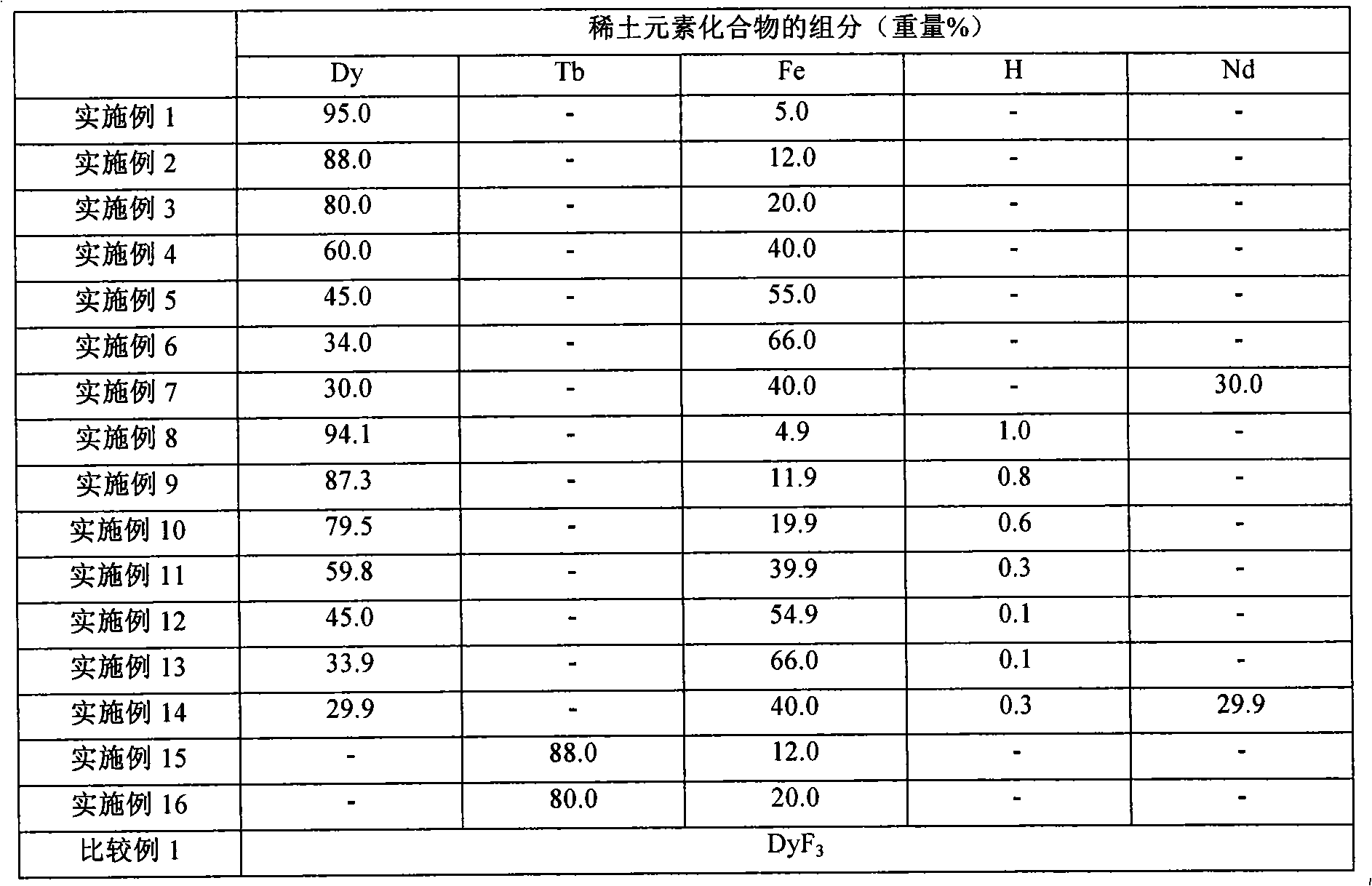

[0043] First of all, prepare the rare earth with composition 23.50wt%Nd-3.50wt%Dy-3.30wt%Pr-0.450wt%Co-0.18wt%Al-0.06wt%Cu-0.97wt%B-bal.Fe The raw material alloy of the magnet. Two types of raw material alloys were prepared: a main-phase alloy mainly forming the main phase of the magnet, and a grain boundary alloy mainly forming grain boundaries. Next, after these raw material alloys were roughly ground by hydrogen pulverization, they were 2 Air jet milling to make them into fine powder with average particle diameter D=4μm.

[0044] The obtained fine powder of the main phase alloy and the fine powder of the grain boundary alloy were mixed at a ratio of the former: the latter = 95:5 to prepare a magnetic powder as a raw material powder of a rare earth magnet. Next, using this magnetic powder, press 1.2t / cm 2 1. Under the condition of an orientation magnetic field of 15 kOe, molding in a magnetic field was performed to obtain a molded body. Then, the obtained molded body was...

Embodiment 2~6

[0049] Rare earth magnets were manufactured in the same manner as in Example 1 except that the composition of DyFe was changed to those shown in Table 1.

Embodiment 7

[0051] A rare earth magnet was manufactured in the same manner as in Example 1 except that DyNdFe having the composition shown in Table 1 was used instead of DyFe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com