A kind of rubber-plastic ferrite magnetic powder and its preparation method, magnetic product and application

A ferrite magnetic, rubber and plastic technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of improving rubber and plastic ferrite magnetic powder, improving and unfavorable magnetic powder Br, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

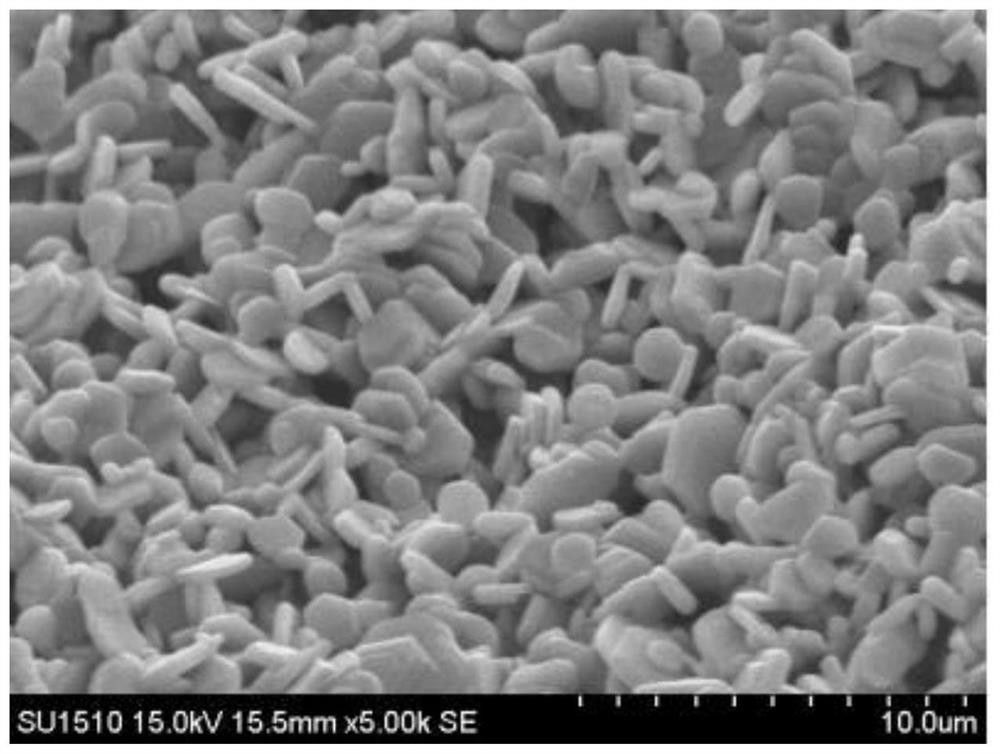

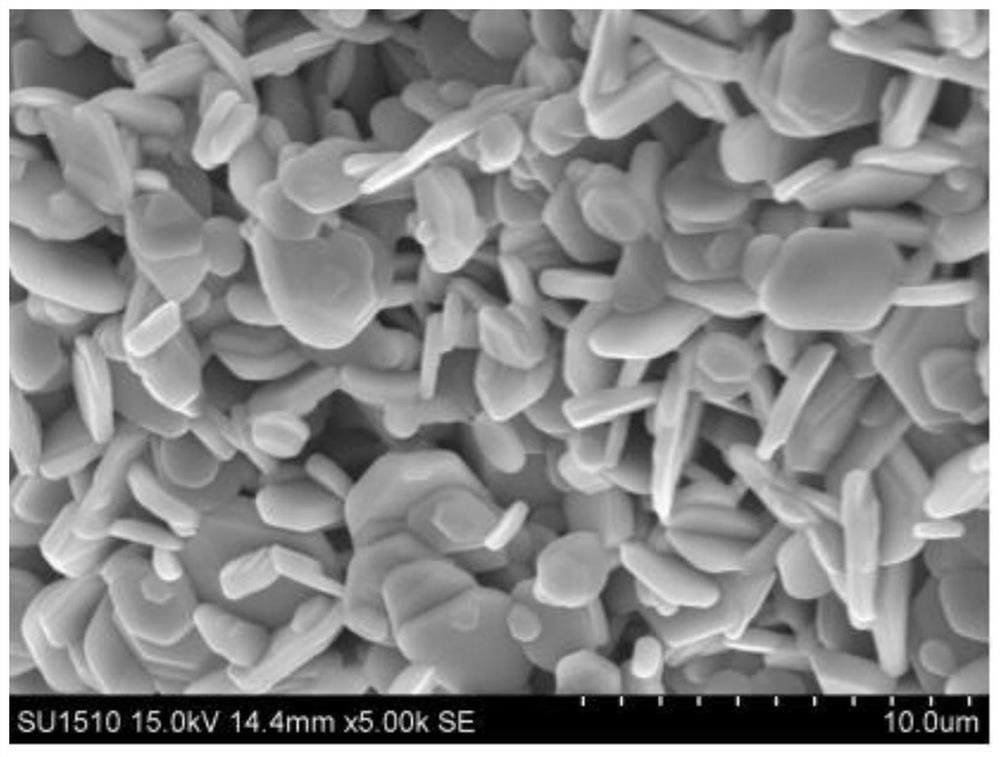

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing the rubber-plastic ferrite magnetic powder described in the above technical solution, comprising the following steps:

[0030] Calcining after mixing iron red, strontium carbonate, manganese carbonate and strontium chloride to obtain calcined pellets, the strontium carbonate raw material is strontium carbonate;

[0031] Sequentially crushing, finely grinding, water washing, dehydrating and drying the calcined balls to obtain rubber and plastic coarse ferrite magnetic powder;

[0032] Tempering the rubber-plastic coarse ferrite magnetic powder to obtain the rubber-plastic ferrite magnetic powder.

[0033] In the present invention, iron red, strontium carbonate, manganese carbonate and strontium chloride are mixed and calcined to obtain calcined pellets, and the strontium carbonate raw material is preferably strontium carbonate.

[0034] In the present invention, described iron red and Fe in strontium carbonate ...

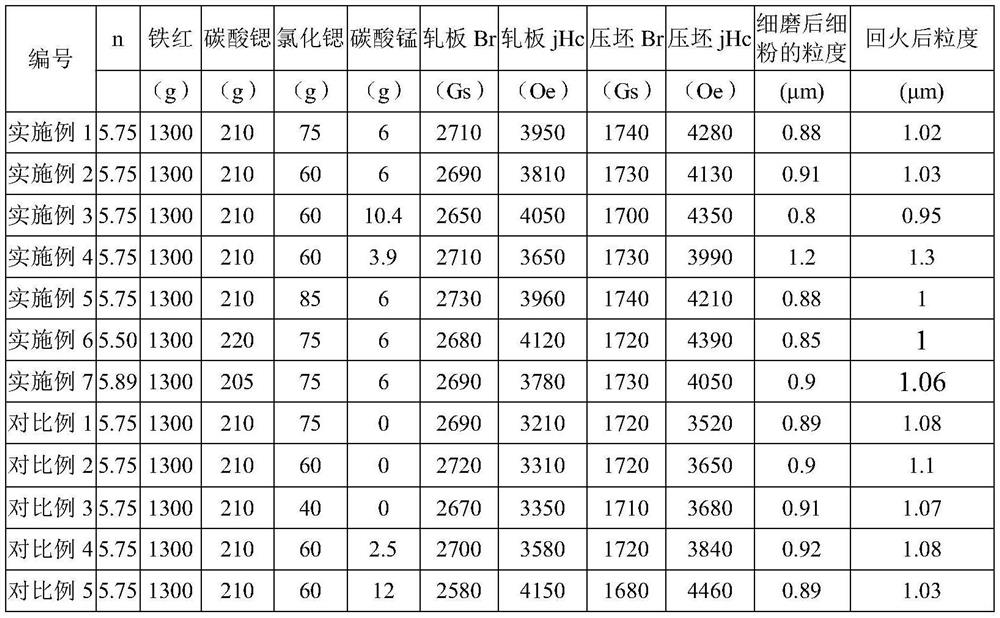

Embodiment 1

[0044] Stir and mix 1300g iron red, 210g strontium carbonate, 75g strontium chloride, and 6.0g manganese carbonate, and pre-calcine at 1080°C for 2 hours to obtain calcined pellets;

[0045] The calcined pellets are crushed to obtain crushed coarse powder with a particle size of 5 μm;

[0046] The crushed coarse powder is wet-milled to obtain a fine powder;

[0047] washing the fine powder with water for 3 times, then dehydrating, and drying, the standard of drying is that the moisture content in the rubber-plastic coarse ferrite magnetic powder is less than 0.50%, to obtain the rubber-plastic coarse ferrite magnetic powder;

[0048] Finally, the rubber and plastic coarse ferrite magnetic powder was tempered, the tempering temperature was 920°C, and the holding time was 35 minutes to obtain the rubber and plastic ferrite magnetic powder; the rubber and plastic ferrite magnetic powder was calendered by calendering to obtain magnetic products.

[0049] Testing of magnetic produ...

Embodiment 2

[0052] Stir and mix 1300g iron red, 210g strontium carbonate, 60g strontium chloride, and 3.9g manganese carbonate, and pre-calcine at 1080°C for 1 hour to obtain calcined pellets;

[0053] Coarsely crushing the calcined pellets to obtain a crushed coarse powder with a particle size of 2 μm;

[0054] The crushed coarse powder is wet-milled to obtain a fine powder;

[0055] washing the fine powder with water for 3 times, then dehydrating, and drying, the standard of drying is that the moisture content in the rubber-plastic coarse ferrite magnetic powder is less than 0.50%, to obtain the rubber-plastic coarse ferrite magnetic powder;

[0056] Finally, the rubber and plastic coarse ferrite magnetic powder is tempered, the tempering temperature is 920°C, and the holding time is 10 minutes to obtain the rubber and plastic ferrite magnetic powder;

[0057] The rubber-plastic ferrite magnetic powder is calendered by a calendering method to obtain a magnetic product.

[0058] Testin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com