Rare earth sintered magnet

A technology of sintered magnets and rare earths, which is applied in the directions of magnetic objects, magnetic materials, transportation and packaging, etc. It can solve problems such as difficult application of grain boundary diffusion method and achieve excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

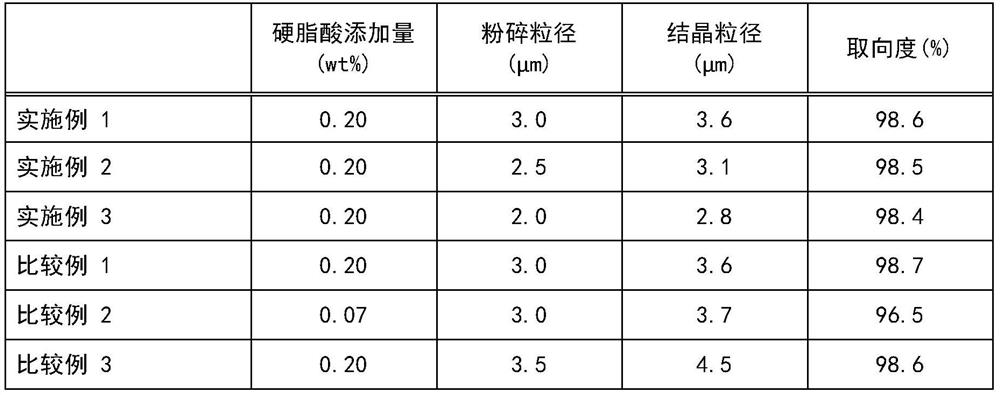

[0070] Nd metal, Pr metal, Dy metal, boron-iron alloy, electrolytic Co, Al metal, Cu metal, Ga metal, Si metal, zirconium metal, and electrolytic iron (all metals with a purity of 99% or more) are called in a predetermined ratio. Quantity and blending, melting, and casting by the strip casting method were performed to obtain a flake-shaped raw material alloy with a thickness of 0.2 to 0.4 mm. The obtained flake-shaped raw material alloy was subjected to hydrogen embrittlement in a hydrogen pressurized atmosphere to obtain a coarsely pulverized powder. Next, to the obtained coarsely pulverized powder, stearic acid as a lubricant was added and mixed in a ratio shown in Table 1 with respect to 100 mass % of the coarsely pulverized powder, and then, using a jet mill (jet mill), nitrogen Dry pulverization was carried out in the stream to obtain the pulverized particle size (D) shown in Table 1. 50 ) of the finely pulverized powder (alloy powder). It should be noted that the pulve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com