Bonded ferrite magnetic powder, preparation method thereof and bonded permanent magnet

A technology of ferrite magnets and bonded magnets, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of high filling rate, difficult to obtain, and difficult to obtain high Br and high jHc at the same time, Achieve the effect of reducing the pre-burning temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

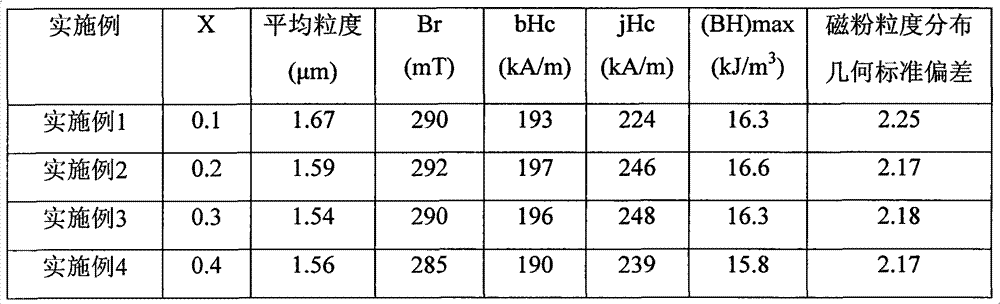

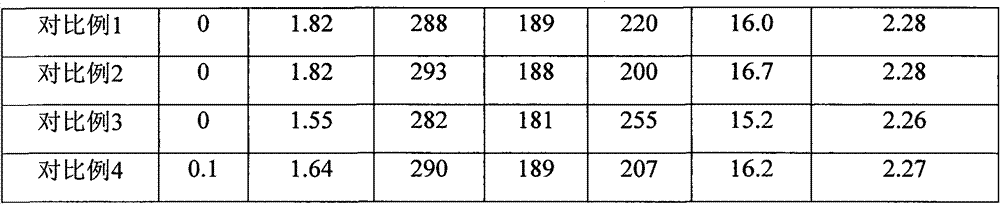

Embodiment 1

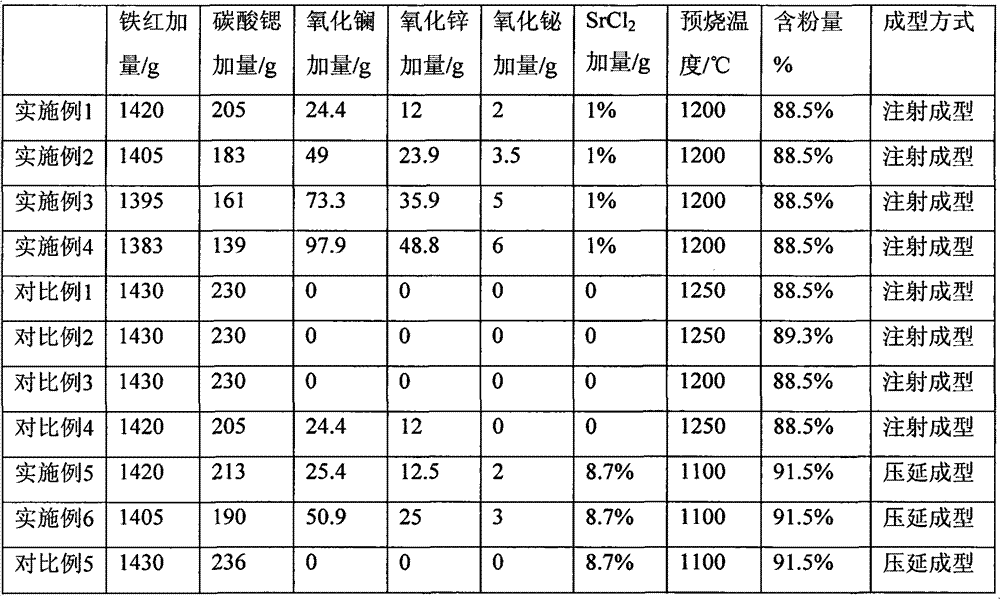

[0045] This embodiment provides a preparation method of bonded ferrite magnetic powder, which specifically includes:

[0046] Weighing 1420g purity is 98.5% iron red, 205g purity is 98% strontium carbonate, 24.4g purity is 98.5% lanthanum oxide, 12 grams purity is 99.2% zinc oxide, 2 grams purity is 99.5% bismuth oxide, Adopt wet type ball mill to mix 3 hours, then dry, obtain compound;

[0047] Weigh 1500 grams of the above mixture, and add 15 grams of strontium chloride SrCl 2 , sintering at 1200°C for 1 hour to obtain pre-sintered material; coarsely crushing the pre-sintered balls with a dry ball mill, followed by fine grinding with a wet ball mill for 3 hours, and drying to obtain a finely ground powder;

[0048] The finely ground powder was annealed at 940°C for 1 hour, and then dispersed to obtain bonded magnetic powder.

[0049] Bonded magnets can be prepared by using the above-mentioned bonded magnetic powder using a molding process, as follows:

[0050] Weigh 1000g...

Embodiment 2

[0055] This embodiment provides a preparation method of bonded ferrite magnetic powder, which specifically includes:

[0056] Weigh 1405g of iron red with a purity of 98.5%, 183g of strontium carbonate with a purity of 98%, 49g of lanthanum oxide with a purity of 98.5%, 23.9 grams of zinc oxide with a purity of 99.2%, and 3.5 grams of bismuth oxide with a purity of 99.5%. The ball mill was mixed for 3 hours, then dried to obtain the mixture;

[0057] Weigh 1500 grams of the mixture prepared above, add 15 grams of strontium chloride, and sinter at 1200° C. for 1 hour to obtain pre-sintered material. Using a dry ball mill to roughly crush the calcined balls, then using a wet ball mill to finely grind them for 3 hours, and drying to obtain finely ground powder;

[0058] The finely ground powder was annealed at 940°C for 1 hour, and then dispersed to obtain bonded magnetic powder.

[0059] Bonded magnets can be prepared by using the above-mentioned bonded magnetic powder using a...

Embodiment 3

[0065] This embodiment provides a preparation method of bonded ferrite magnetic powder, which specifically includes:

[0066] Weighing 1395g purity is 98.5% iron red, 161g purity is 98% strontium carbonate, 73.3g purity is 98.5% lanthanum oxide, 35.9 grams purity is 99.2% zinc oxide, 5 grams purity is 99.5% bismuth oxide, The mixture was mixed in a wet ball mill for 3 hours, and then dried to obtain a mixture.

[0067] Weigh 1500 g of the mixed material, add 15 g of strontium chloride, and sinter at 1200° C. for 1 hour to obtain pre-sintered material. The calcined balls were coarsely broken by a dry ball mill, then finely ground by a wet ball mill for 3 hours, and dried to obtain a finely ground powder.

[0068] The finely ground powder was annealed at 940°C for 1 hour, and then dispersed to obtain bonded magnetic powder.

[0069] Weigh 1000g of bonded magnetic powder, 110g of nylon 6 and 20g of related additives (silane coupling agent and lubricant TAF), after mixing evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com