Connection device of locomotive cowcatcher

A technology of connecting device and obstacle remover, which is applied in the direction of thin plate connection, connecting member, wheel guard/buffer of railway vehicles, etc., can solve the problems of poor bolt tightening, inconvenient adjustment of the obstacle remover, and slipping of the obstacle remover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

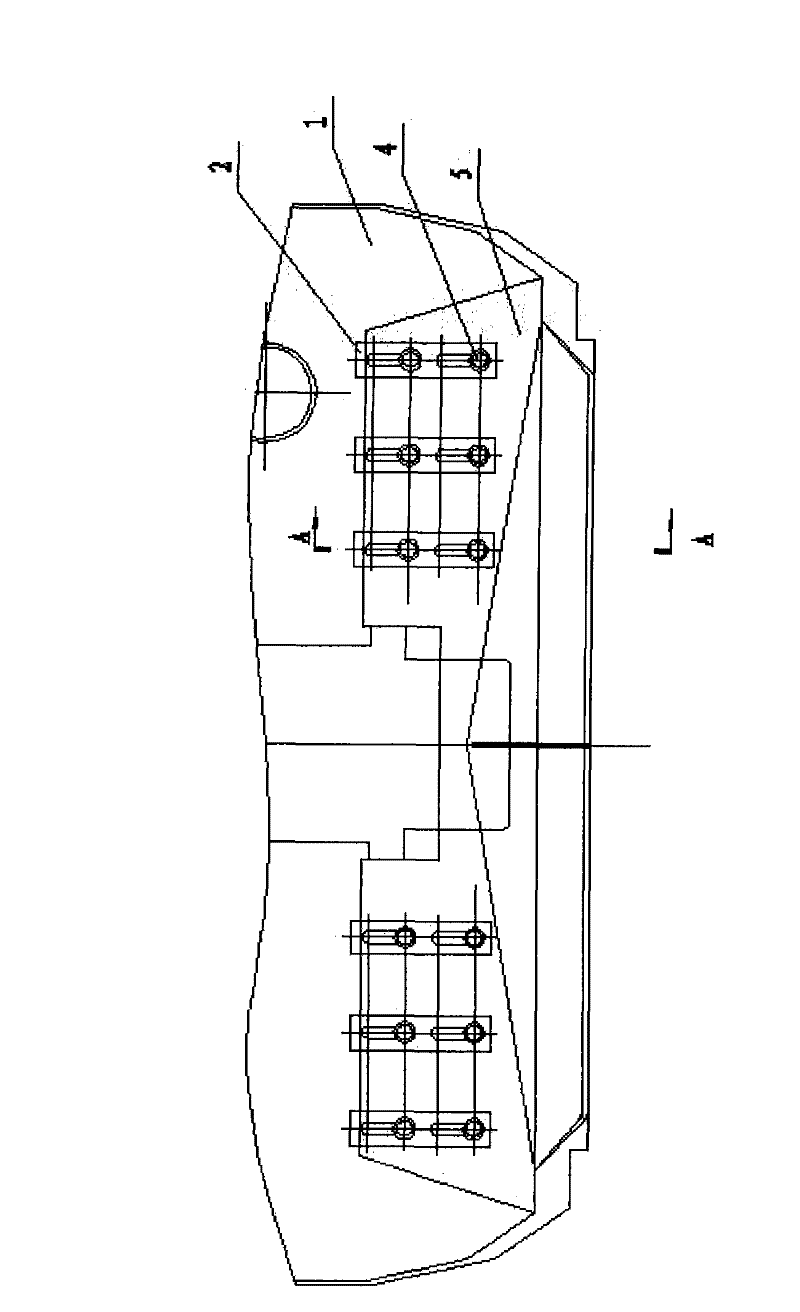

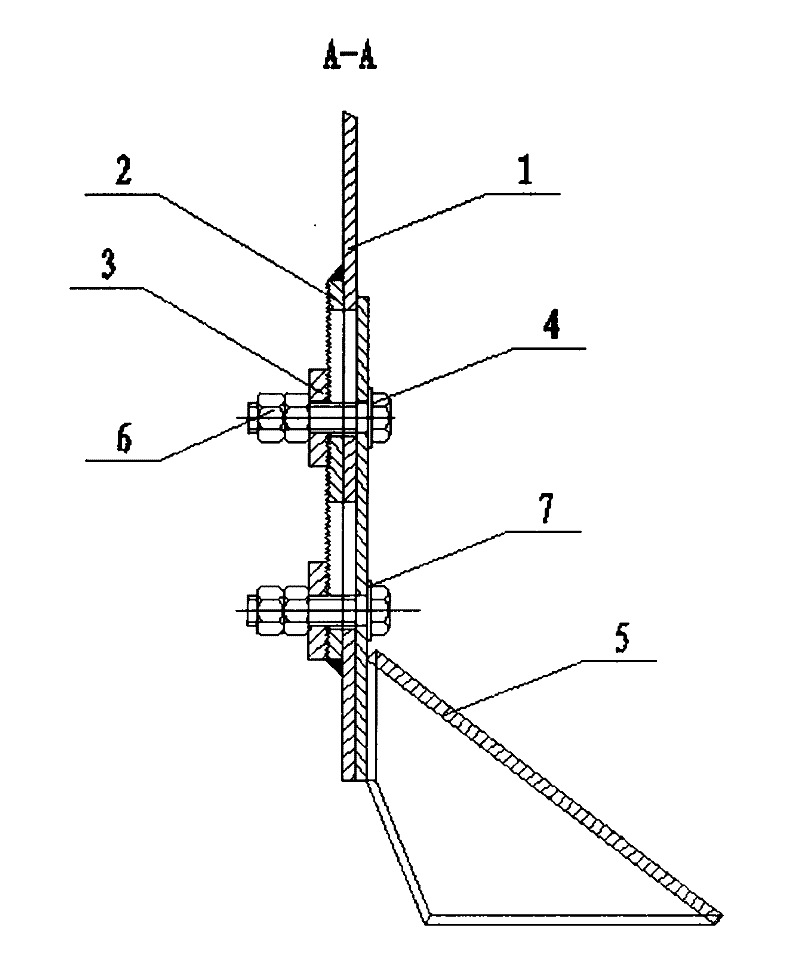

[0012] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

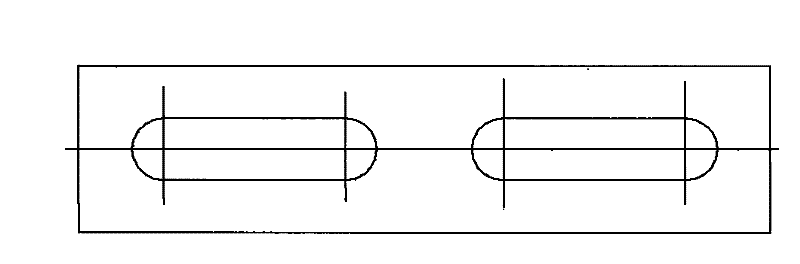

[0013] Such as figure 1 with figure 2 As shown, it is a structural schematic diagram of the connecting device of the locomotive obstacle remover of the present invention, and the fixing hole where the front end plate 1 of the locomotive is connected with the obstacle remover 5 is welded with the fixing plate 2 (such as image 3 As shown), the fixed plate 2 and the front end plate 1 are all processed with long strip through holes, and the fixed plate 2 has a surface that is processed into a zigzag surface, and the movable block 3 (such as Figure 4 shown) also has a surface that is processed into a sawtooth-shaped surface, and the fixed plate 2 and the movable block 3 have the same sawtooth shape, which can be an equilateral triangle (such as Figure 5 shown), it can also be an isosceles trapezoid. The bolt 4 passes through the washer 7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com