Pipe-bundle-builtin isothermal-shift reactor

A technology of isothermal transformation and reactor, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of difficult control of temperature rise, influence on structural reliability, and many materials used, so as to avoid large temperature rise, The effect of short weld seams and unlimited height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

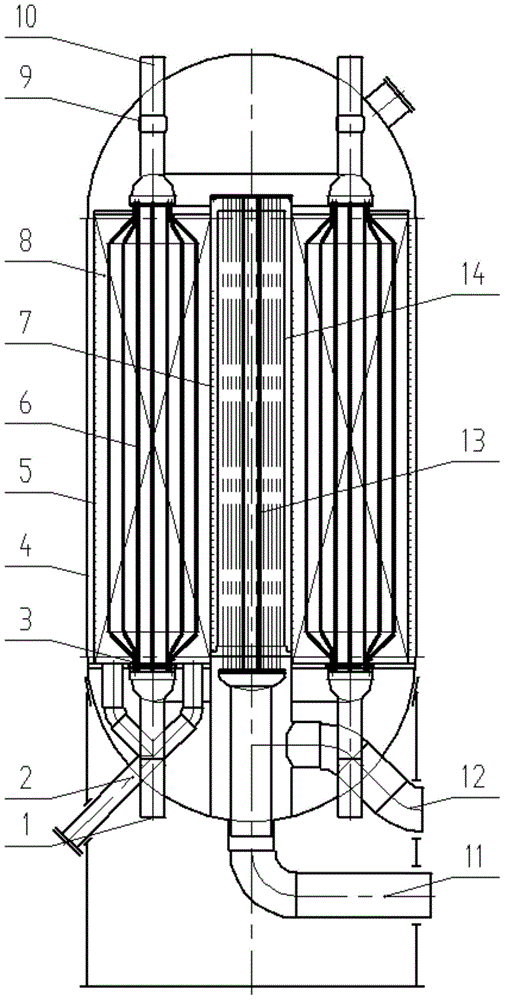

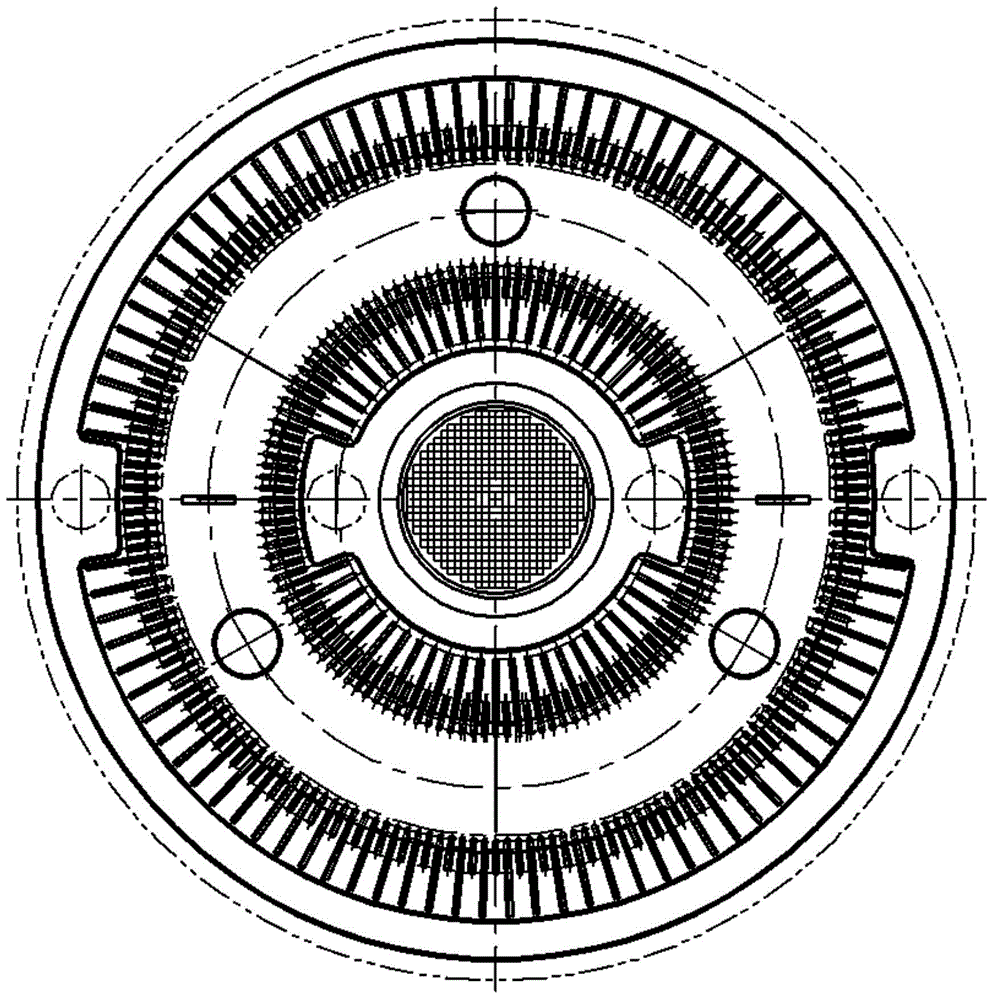

[0041] Such as figure 1 and figure 2 As shown, an isothermal shift reactor with a built-in tube bundle includes a pressure-bearing shell (4), a feed gas inlet (11), a shift gas outlet (12), and a boiler water inlet ( 1), the boiler water outlet (10) and the catalyst discharge port (2), and the catalyst basket (5) arranged in the pressure housing (4), the axial annular tube bundle (6), the central tube (7), Ring chamber body (14), and central tube bundle (13). The axial annular tube bundle (6) is connected with the boiler water outlet (10) by an expansion joint (9) to absorb the thermal expansion deformation difference between the tube bundle and the casing. The catalyst (8) is contained in the catalyst basket (5), outside the central tube (7) and in the gap of the axial annular tube bundle. Such as Figure 5 The shown axial annular tube bundle (6) is a boiler water distributor composed of the lower annular tube box (6-2) and the lower annular tube sheet (6-3), the upper a...

Embodiment 2

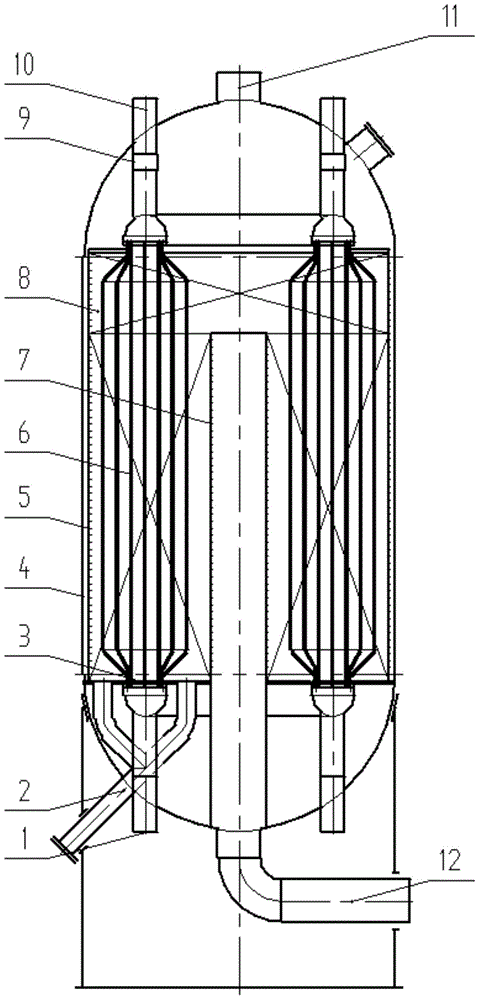

[0044] Such as image 3 and Figure 4 As shown, a built-in tube bundle isothermal shift reactor, which moves the central tube bundle (13) heat exchanger in the central tube (7) out of the reactor; the raw material gas enters from the upper raw material gas inlet (11) of the reactor, and is distributed to The annular cavity between the pressure-bearing shell (4) and the catalyst basket (5) enters the catalyst bed (8) through the hole array on the catalyst basket (5), reacts under the action of the catalyst, releases heat, and the reaction heat is large Part of it is taken away by the boiler water in the axial annular tube bundle (6) uniformly distributed in the bed, and the shifted gas after reaction is collected by the central tube (7) and leaves the reactor through the lower shifted gas outlet (12).

[0045] In the isothermal shift reactor with built-in tube bundle in another embodiment, the gas-gas heat exchanger located in the central tube (7)——the central tube bundle (13)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com