Diluting and cooling device

A technology of a cooling device and a driving device, which is applied in the field of devices for preliminary cooling of high-temperature gas, and can solve problems such as skin blockage, burning loss of the extraction device, and failure to effectively reduce the temperature of the extracted gas, so as to prolong the service life and reduce the temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

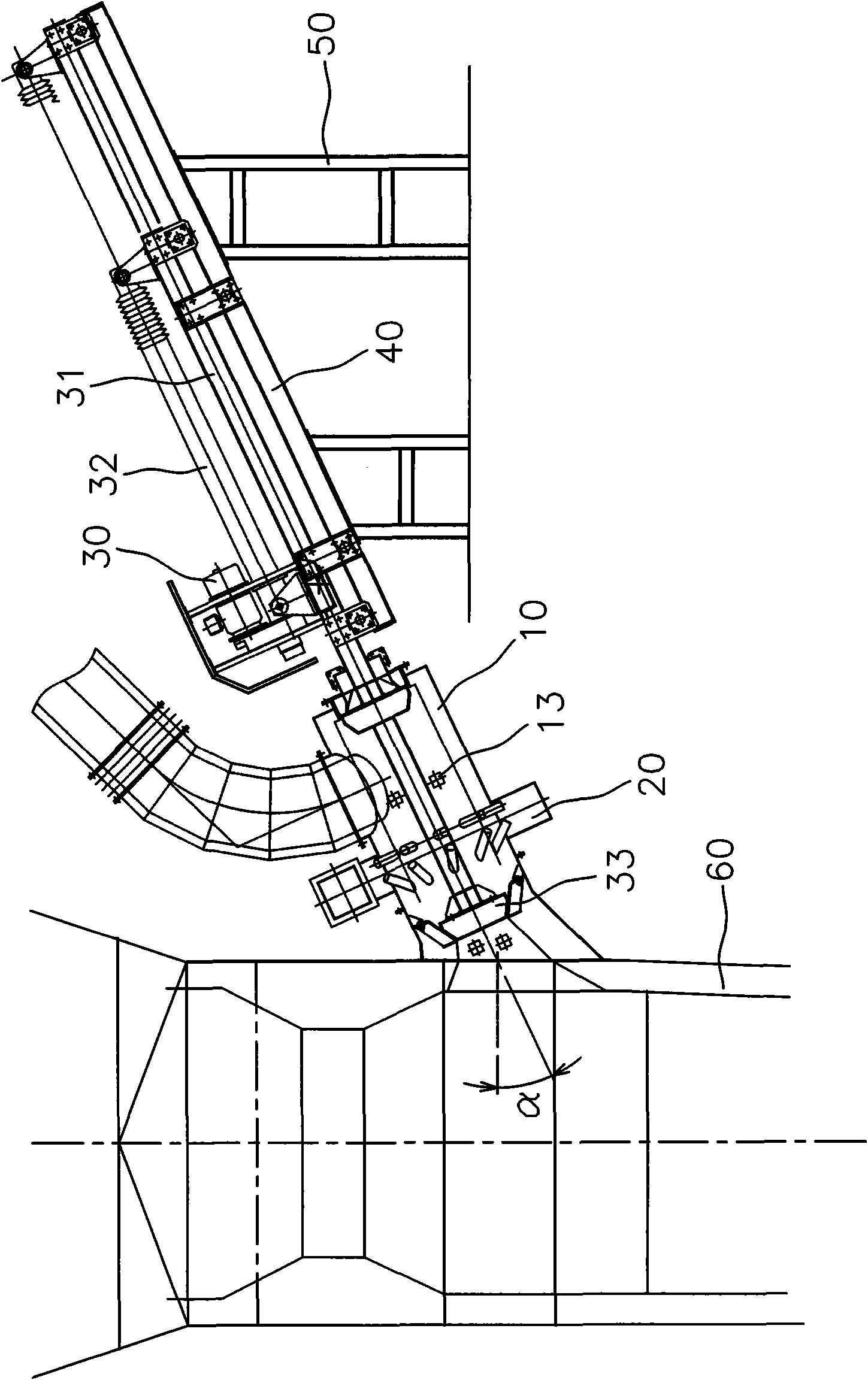

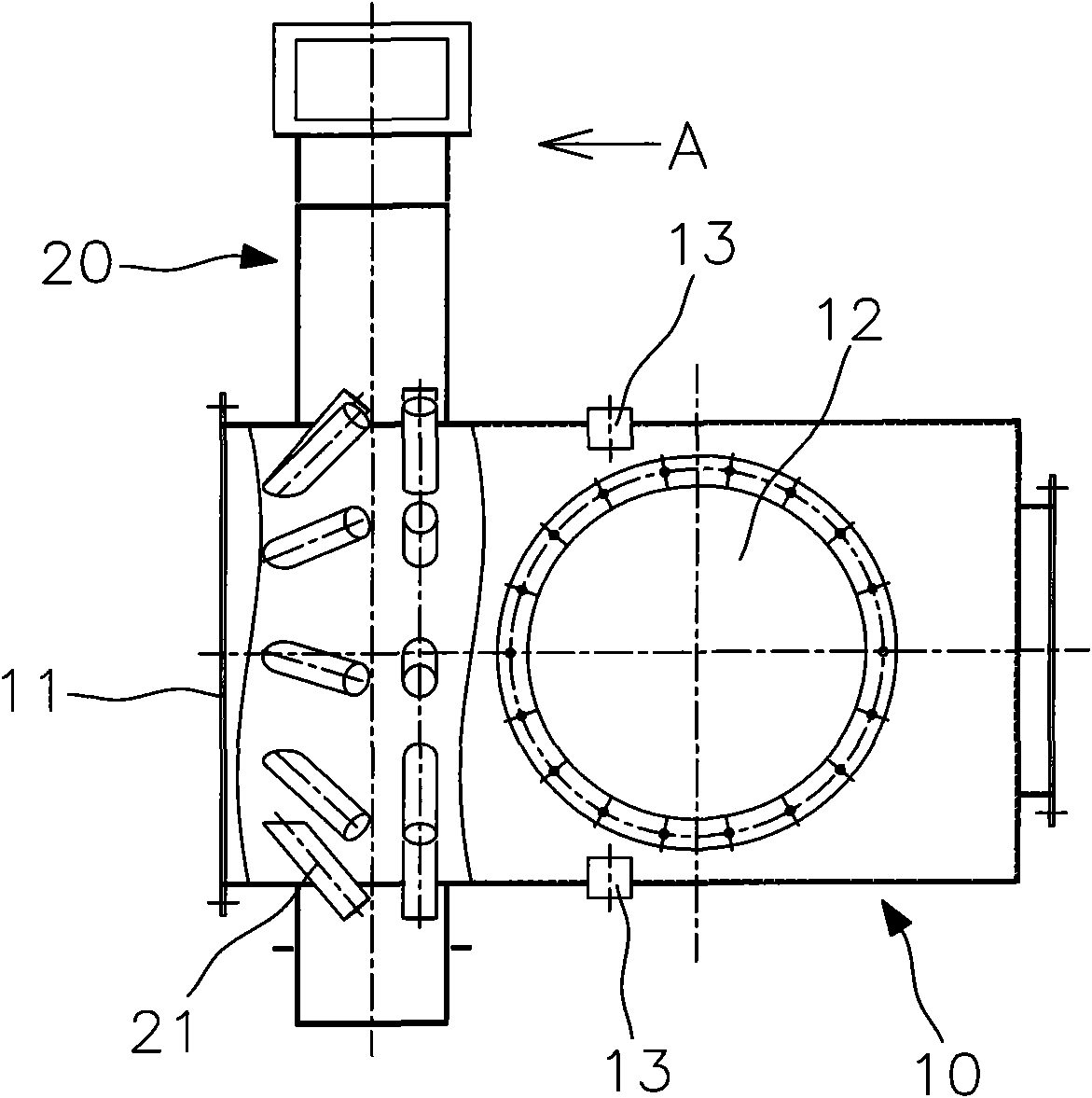

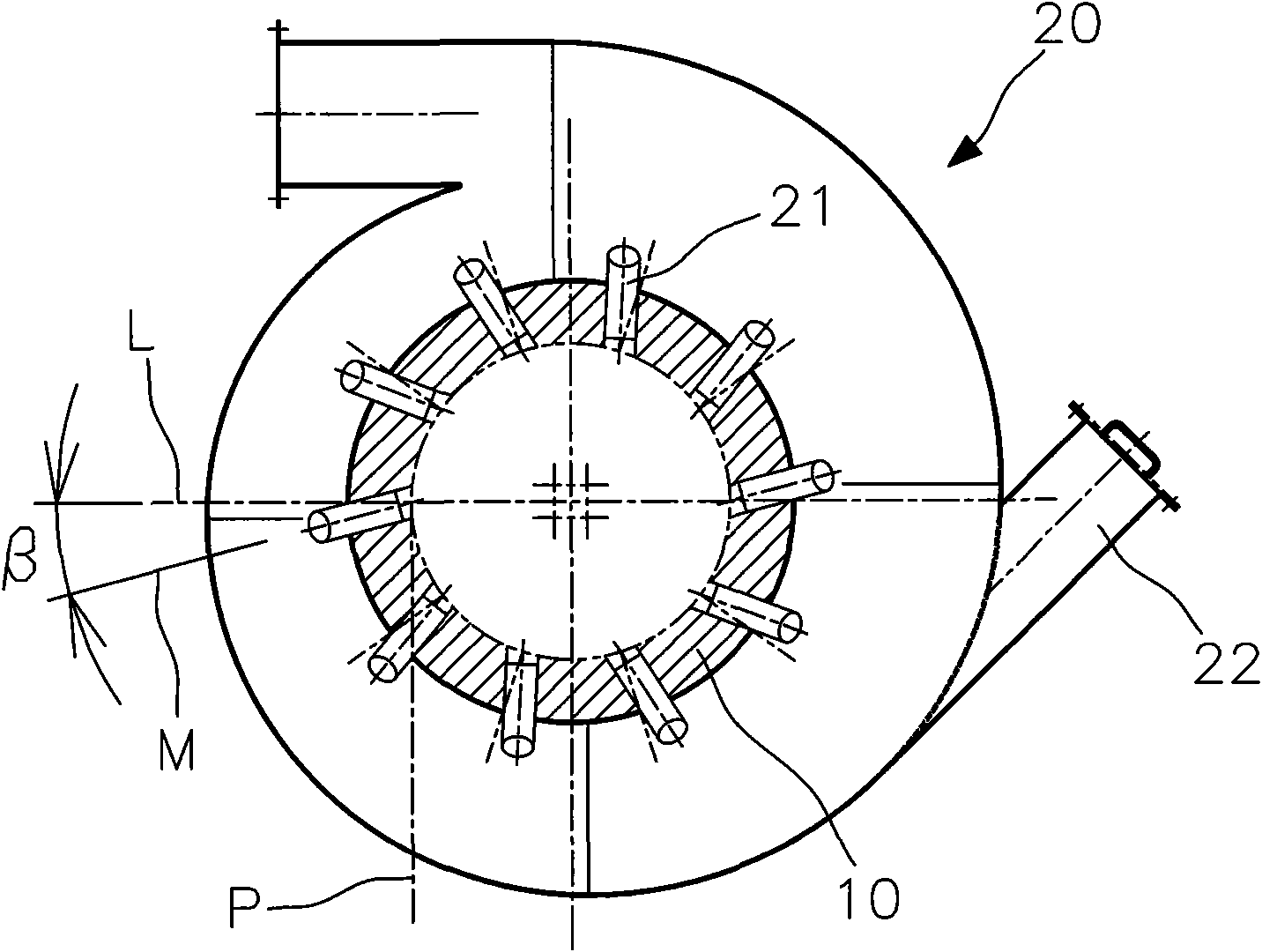

[0010] like Figure 1~4 As shown, a dilution cooling device, the dilution cooling device includes a hollow housing 10, the two ends of the housing 10 are respectively provided with an air inlet 11 and an air outlet 12, and the housing 10 is provided with a The housing 10 is provided with a valve plate 33 connected to the driving device, and the driving device drives the valve plate 33 so that the air inlet 11 of the housing 10 is in an open or closed state.

[0011] The air inlet end of the cold air pipe 20 may or may not be provided with a cooling fan. When the air inlet end of the cold air pipe 20 is not provided with a cooling fan, the cold air pipe should be sucked into the casing in the form of jet flow. body 10 to achieve uniform mixing of cold wind and high-temperature gas.

[0012] As a preferred solution of the present invention, the air outlet 12 is provided with an exhaust pipe connected to the exhaust fan, and the air inlet end of the cold air pipe 20 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com