Heat pipe radiating device used in high power LED (light emitting diode) street lamp

A technology for LED street lamps and cooling devices, which is applied to cooling/heating devices of lighting devices, lighting devices, lighting and heating equipment, etc. It can solve the problems of slow heat dissipation, volatilization, and failure of cooling devices to dissipate heat normally, so as to save construction costs, The effect of prolonging the service life and protecting from burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

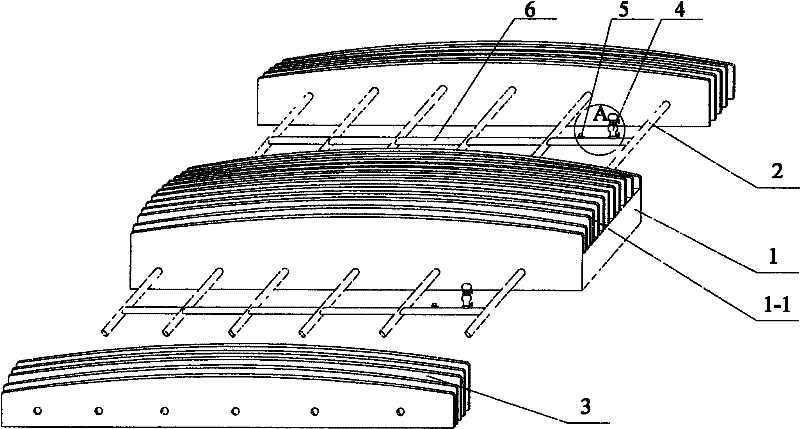

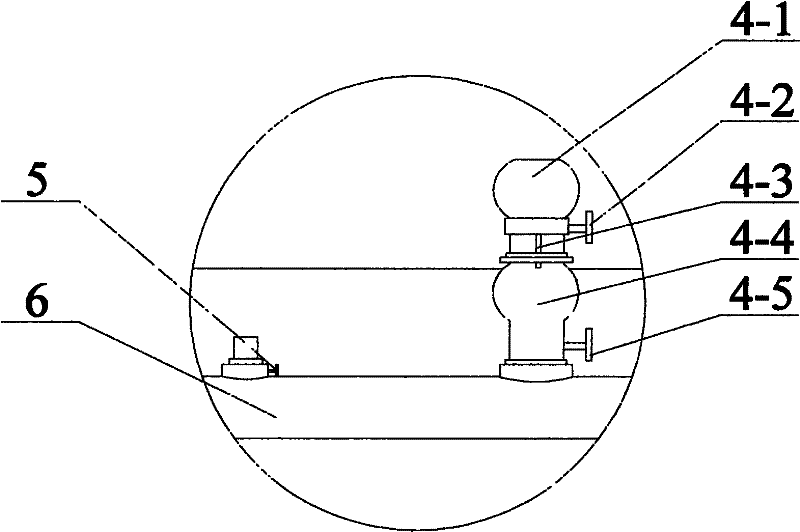

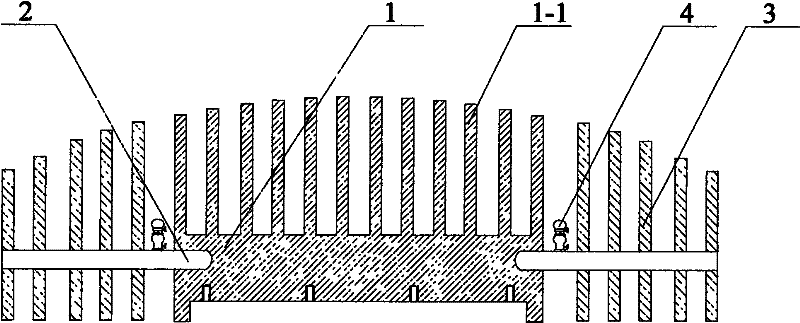

[0015] see figure 1 , a heat pipe cooling device used in high-power LED street lamps, the heat collecting end of the heat pipe 2 in the above device is inserted into the heat conducting base panel 1 where the LED lamp body is positioned in the lamp pool, and a group of separate heat dissipation devices are provided at the heat dissipation end of the heat pipe 2 The fins 3 add a negative pressure adjustment interface communicating with the lumen of the heat pipe 2 and a heat transfer medium replenishment mechanism 4 in the structure of the heat pipe 2 .

[0016] At least two independent heat pipes 2 are arranged in the structure of the above-mentioned heat pipe cooling device.

[0017] Connecting pipes 6 connecting the lumens of the heat pipes 2 are added between the independent heat pipes 2, and the negative pressure adjustment interface of the lumens of the heat pipes 2 and the heat transfer medium replenishment mechanism 4 are arranged on the tube walls of the heat pipes 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com