Enclosure method for inserting H-shaped reinforced concrete slab piles in three-axis (two-axis) cement mixing pile

A technology of cement-soil mixing piles and reinforced concrete sheet piles, which is applied to sheet pile walls, excavation, construction, etc., can solve the problems of long construction period in the basement, high cost of H-shaped steel, and high rental fees, so as to improve the degree of civilization and resist Good bending performance and good stress structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

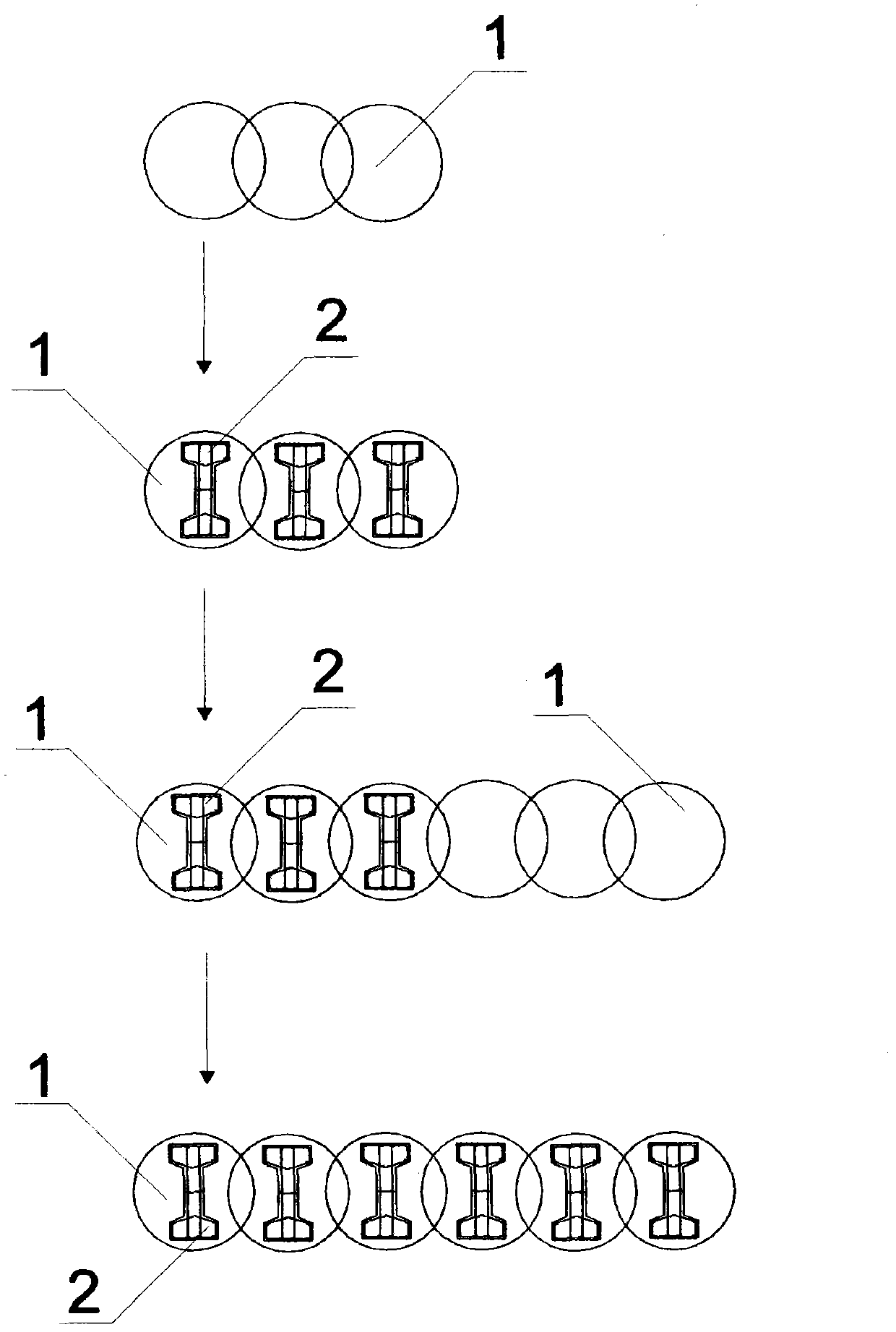

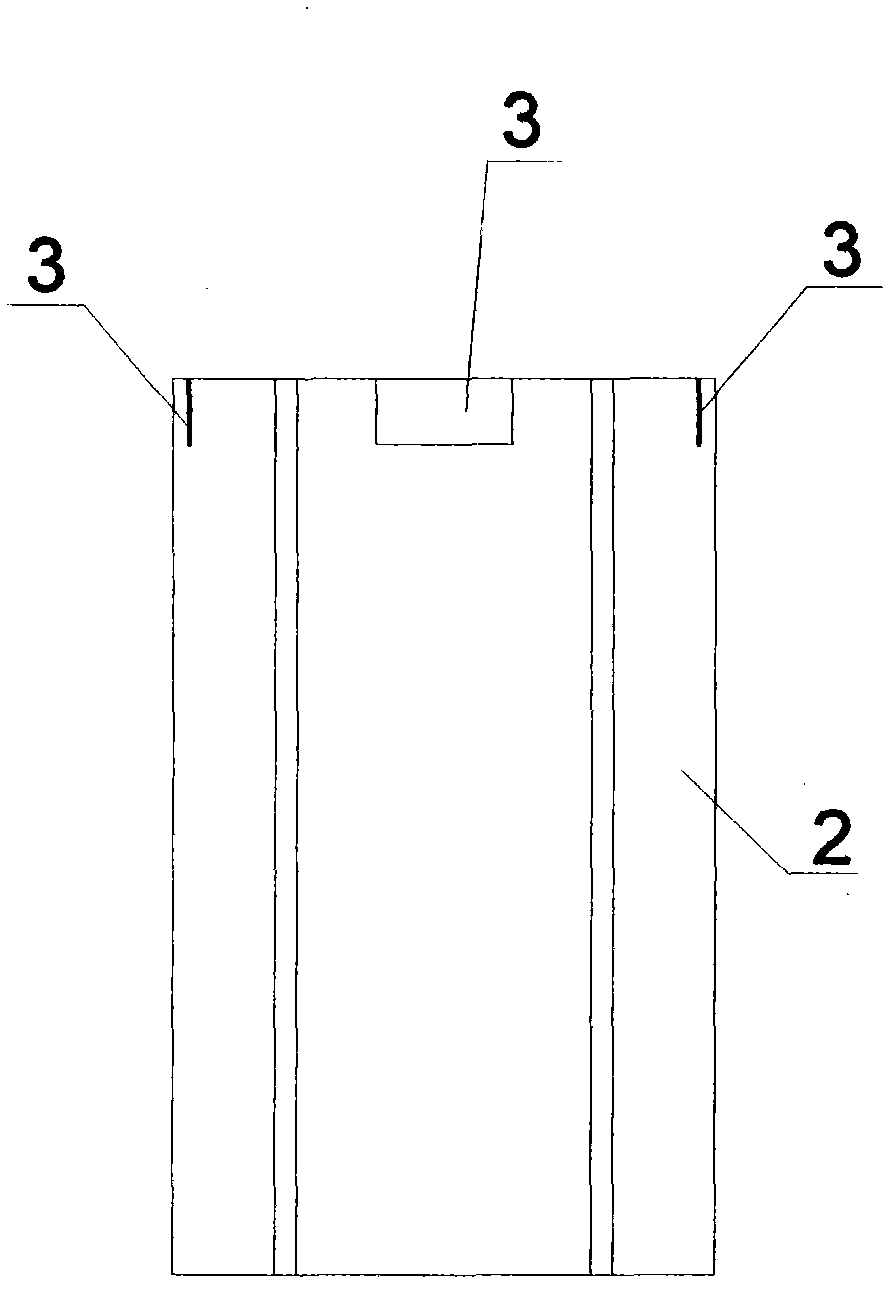

[0019] Such as Figure 1-5 The enclosing method of inserting H-shaped reinforced concrete sheet piles in the shown three-axis (two-axis) cement-soil mixing piles includes making H-shaped reinforced concrete sheet piles 2, digging the ground to form three-axis (two-axis) cement-soil mixing piles 1, and placing The H-shaped reinforced concrete sheet pile 2 is inserted into the three-axis (two-axis) cement-soil mixing pile 1 in three processes.

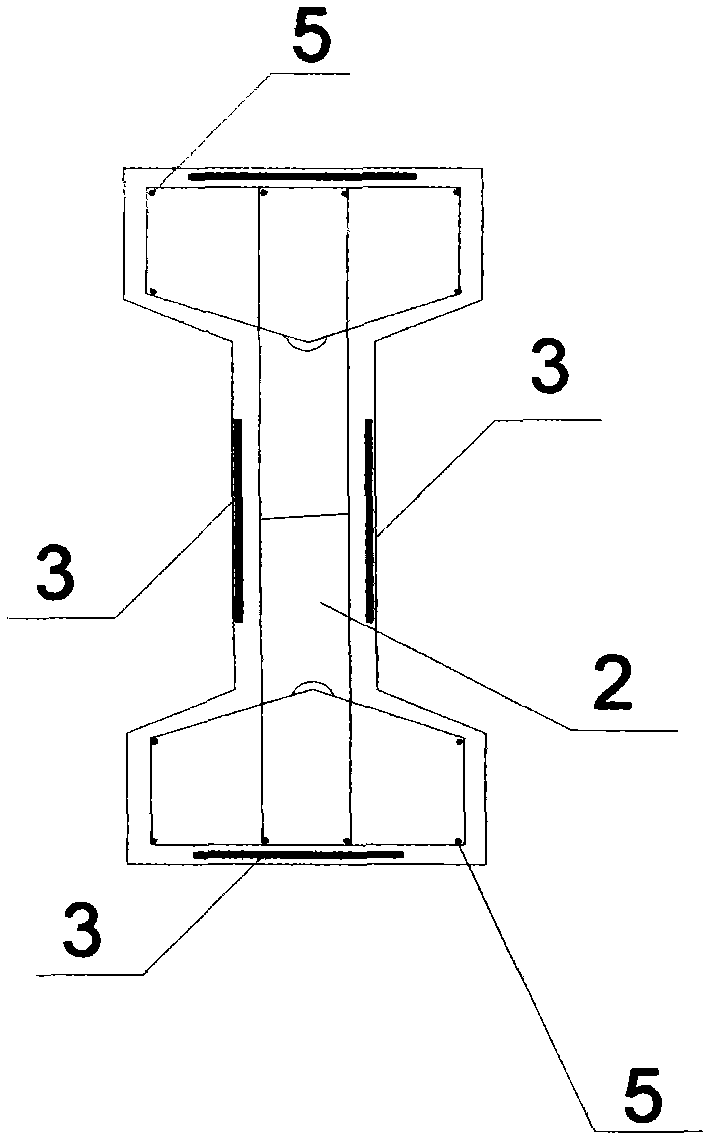

[0020] The H-shaped reinforced concrete sheet pile 2 is configured with a plurality of steel bars 5, the number of the described steel bars 5 is determined according to needs, and several embedded iron 3 are arranged around one end of the H-shaped reinforced concrete sheet pile 2, The pre-embedded iron 3 plays the role of welding between the H-shaped reinforced concrete sheet piles 2, and the production of the H-shaped reinforced concrete sheet piles 2 can be carried out before construction, and different lengths can be made according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com