Airbag laminating device and method for curved glass on touch screen

A curved glass and bonding device technology, applied in lamination devices, chemical instruments and methods, layered products, etc., can solve the problem that the curved part of the main airbag 3 and the curved glass 6 cannot be completely overlapped and the curved part of the curved glass 6 Small force, easy to appear bubbles and other problems, to increase pressure, eliminate lamination air bubbles, increase the effect of lamination fat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

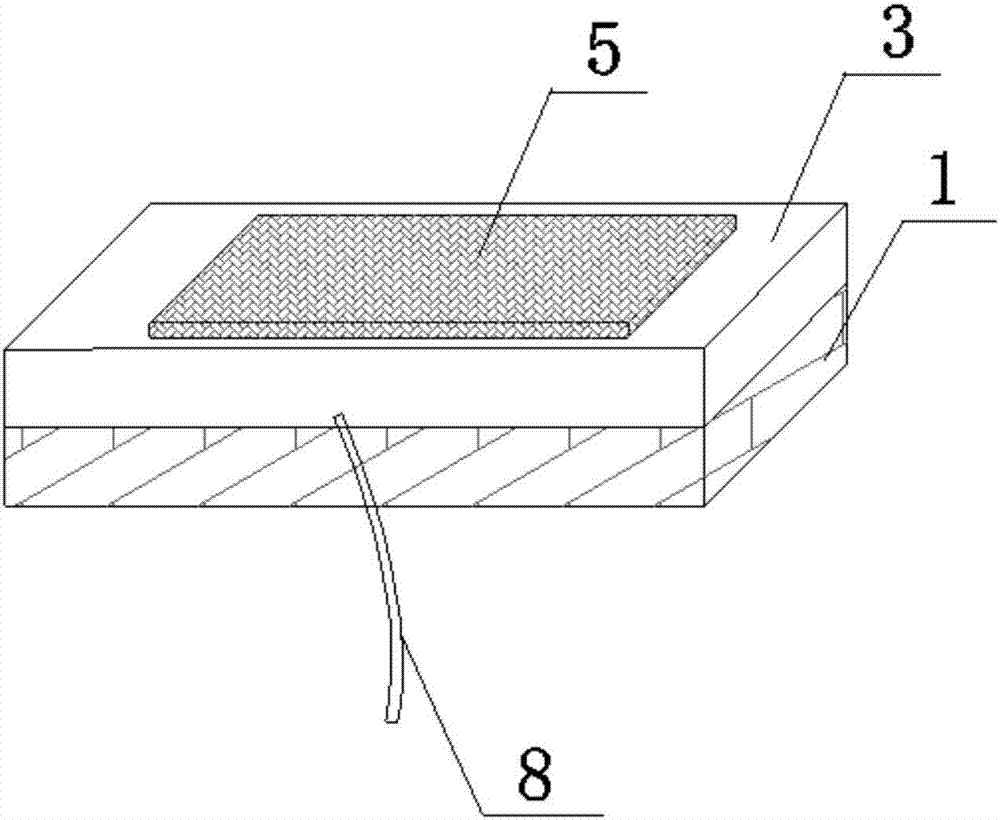

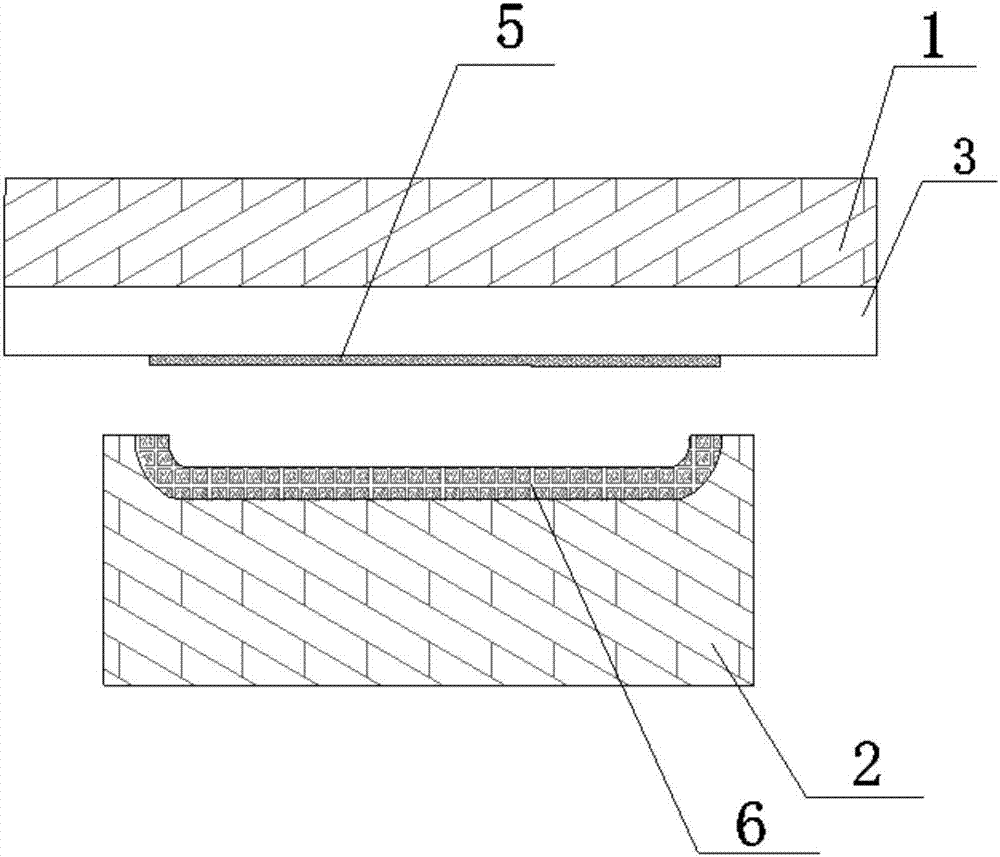

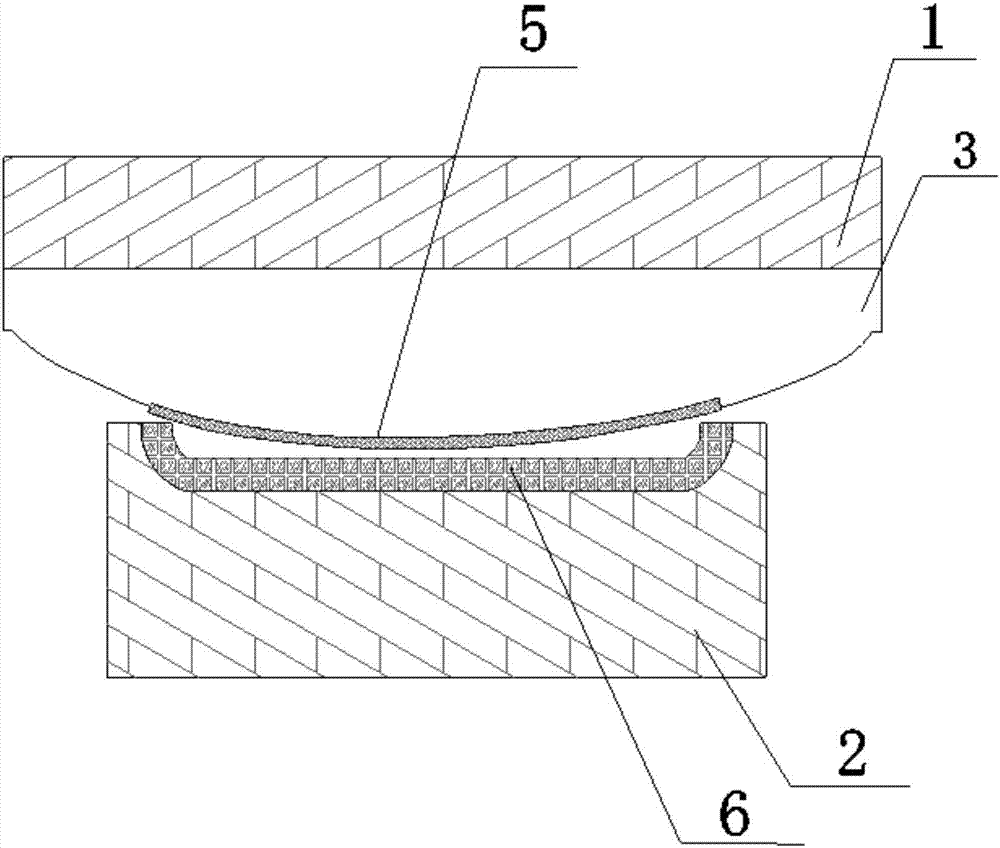

[0047]On the one hand, this application proposes an airbag bonding device for curved glass on a touch screen, see Figure 5 , a schematic diagram of the airbag fitting device. An airbag bonding device for curved glass on a touch screen, comprising a support plate 1 and a jig table 2 located below the support plate 1, the jig table 2 is used to position the curved glass 6, and the support plate 1 A main airbag 3 is provided on one side close to the jig table 2, and an auxiliary airbag 4 is provided at a position corresponding to the curved portion of the curved glass 6 inside the main airbag 3, and the auxiliary airbag 4 is used to closely attach the flexible film 5 to the The curved portion of the curved glass 6 is described.

[0048] This airbag bonding device improves the stress structure of the curved portion of the curved glass 6 during bonding by setting the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com