Non-bearing independently driven electric axle

An independent drive, electric vehicle technology, applied in electric power units, axles, wheels, etc., can solve the problems of wheel-side motor and wheel-hub motor technical difficulty, direct-connected unsprung mass, high manufacturing cost, and improve acceleration. Effects of stable operability, reduced difficulty in manufacturing and assembly, and shortened manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

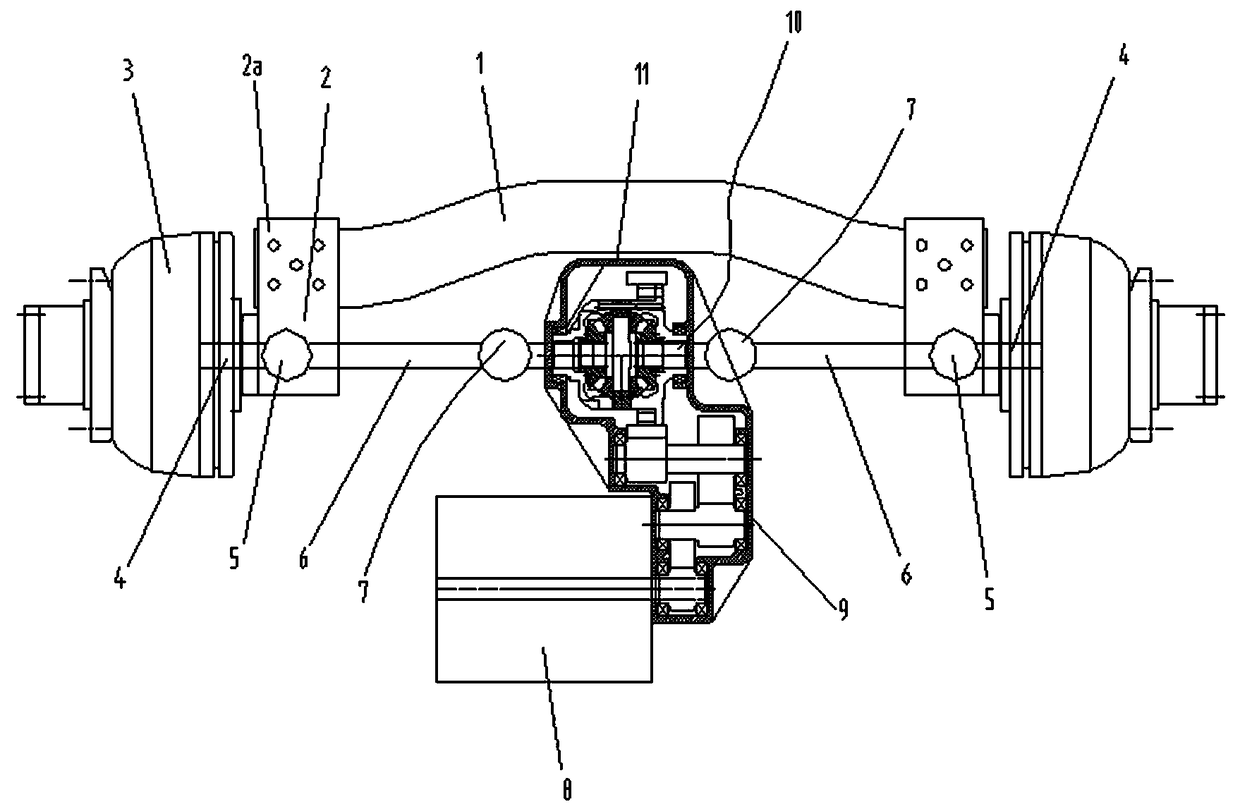

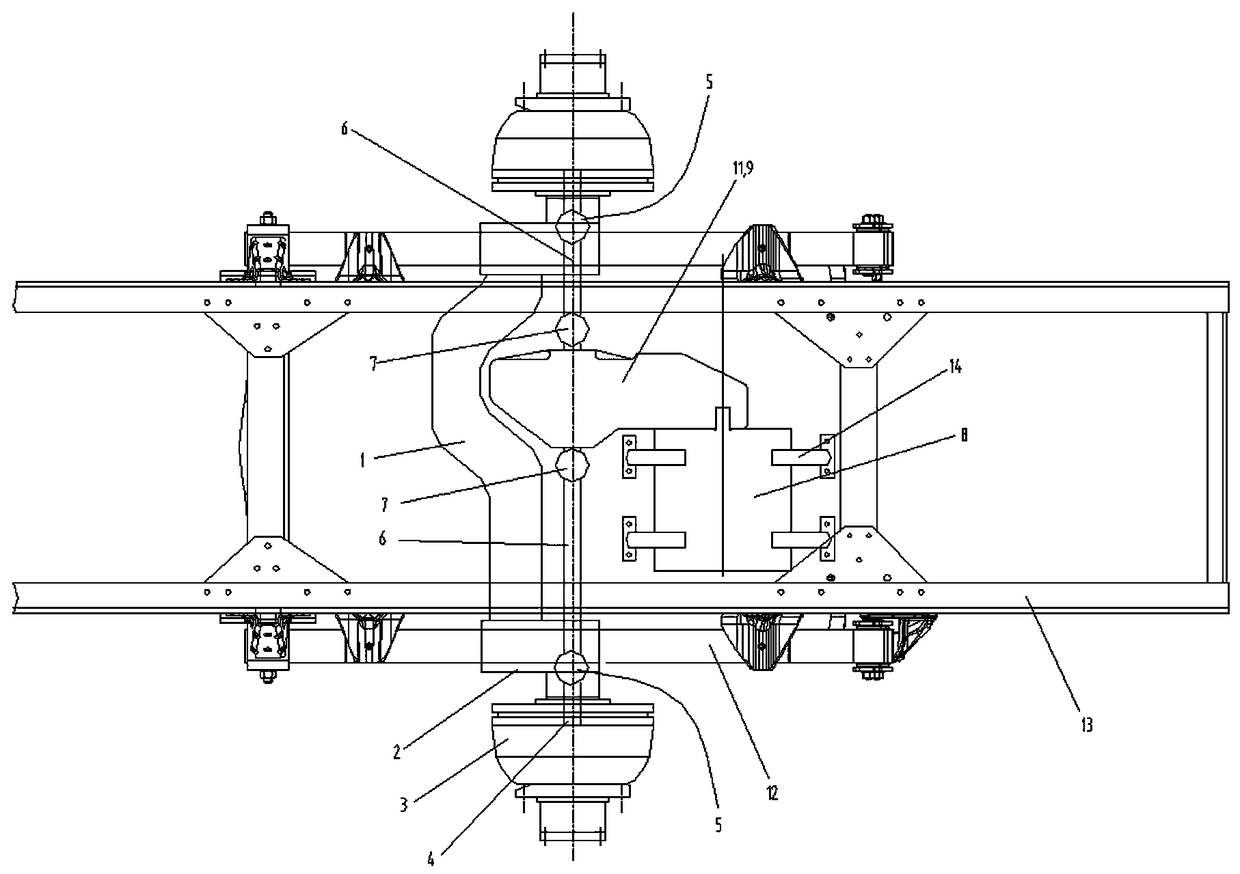

[0019] Such as figure 1 , figure 2 As shown, a non-load-bearing independent drive electric axle provided by the present invention includes a vehicle frame 13, a group of leaf springs 12 are respectively provided on both sides of the vehicle frame, and a wheel end connecting bracket 2 is respectively provided on both sides of the vehicle frame 13, Each wheel end connecting bracket 2 is respectively provided with a steel bracket 2a, and the steel bracket 2a is arranged at the position where the integral load-bearing axle housing 1 is connected with the wheel end connecting bracket 2, so that the integral load-bearing axle housing and the wheel end system The axis forms an offset setting, and the middle part of the integral load-bearing axle housing 1 is also provided with a concave structure for the differential 11 .

[0020] Each steel bracket 2a is connected to a corresponding group of leaf springs 12; each wheel end connecting bracket 2 is connected to the corresponding whe...

Embodiment 2

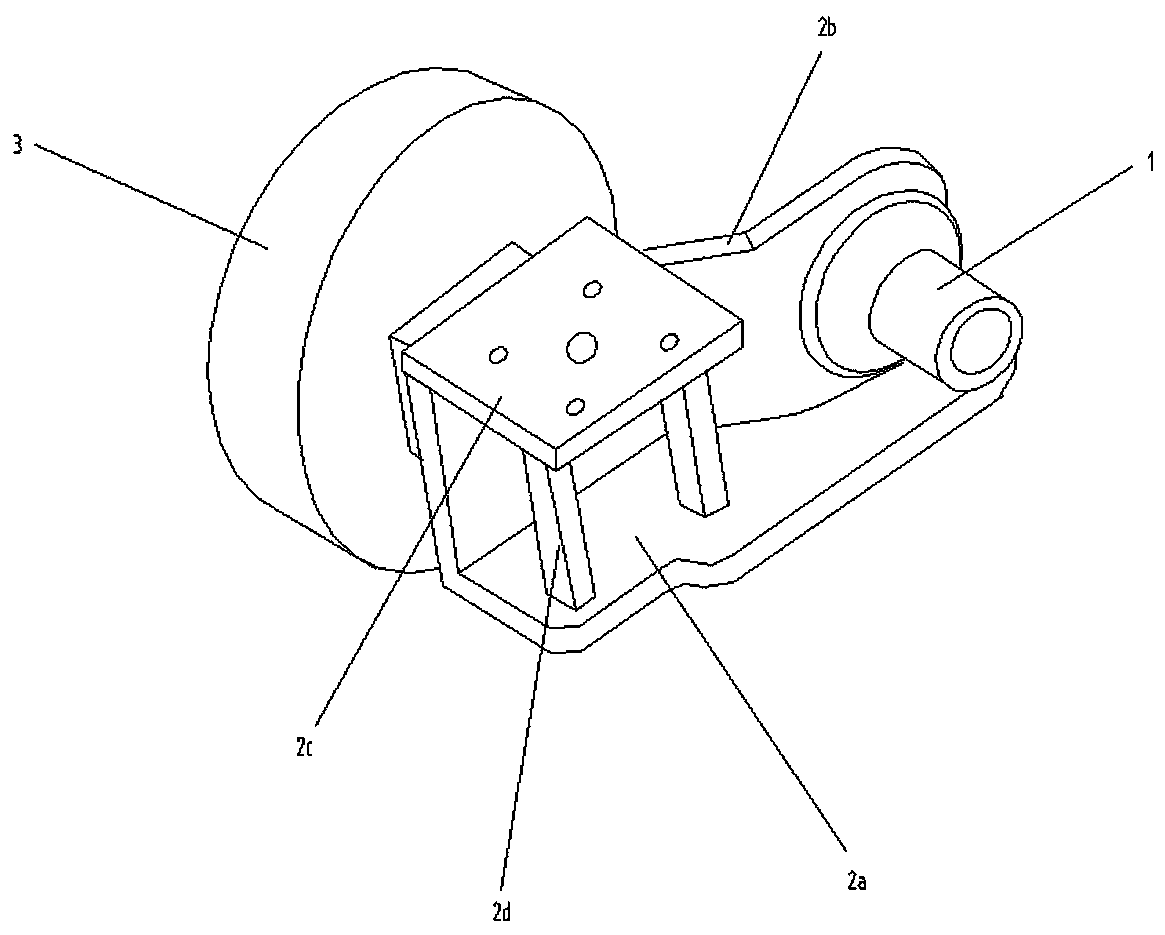

[0023] Such as image 3 As shown, the wheel end connection bracket 2 includes a bottom plate 2a and its connected vertical plate 2b, one side of the vertical plate 2b is connected to the wheel end system 3, and the other side is connected to the integral load-bearing axle housing 1, and the steel bracket 2a is arranged on the wheel end Where the system 3 is located, one side is connected to the vertical plate 2b, and the other side is connected to the bottom plate 2a by a set of columns 2d.

[0024] The invention can effectively reduce the unsprung mass of the whole vehicle, improve the acceleration and driving stability of the whole vehicle, and at the same time meet the load and transmission requirements of light commercial vehicles. The independent design is conducive to the implementation of product modularization. In terms of installation and maintenance, compared with the electric drive axle with a central motor direct-connection structure, it has huge application advant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com