Manufacturing method of assembled stationary blade partition plate of rotary drum steam turbine

A manufacturing method and technology for steam turbines, which are applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of cumbersome processing procedures of separators, unsatisfactory welding performance, and difficulty in finding the center of the rotor, so as to avoid the problem of unsatisfactory welding performance. , Improve the accuracy and efficiency of center finding, and improve the effect of physical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

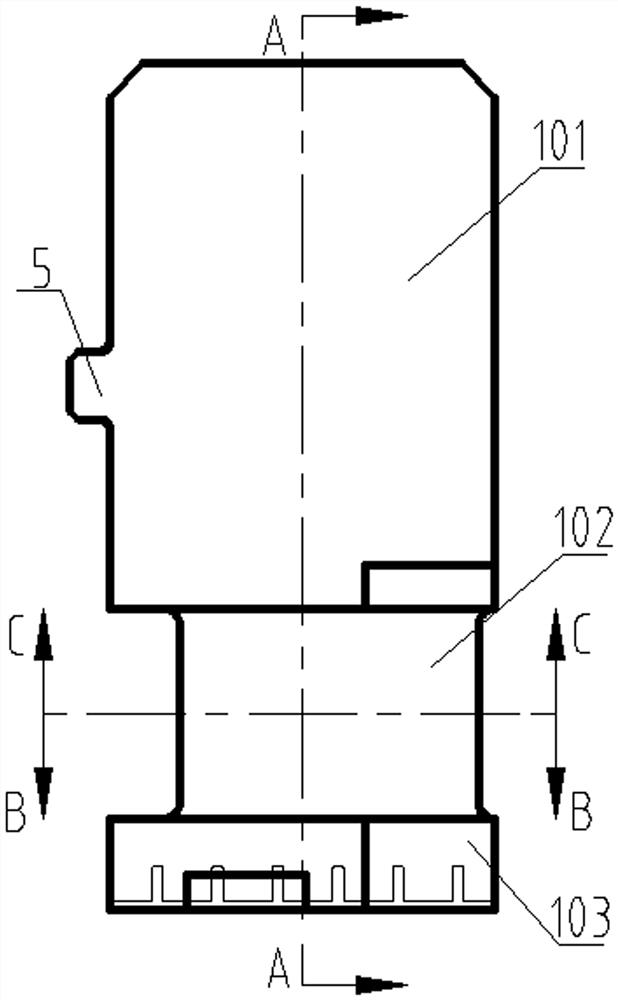

[0037] A method for manufacturing a drum-type steam turbine assembled stationary vane diaphragm, the diaphragm is assembled from 46 stationary vanes 1 to form a full circle, and the manufacturing method includes the following steps:

[0038] (1) Grouping: Divide group scoring lines on the assembly end of the partition sleeve, divide the assembly end of the partition sleeve into 6 assembly groups, all the grouping scoring lines are distributed in a circular array, and the annular array and the partition sleeve coaxial;

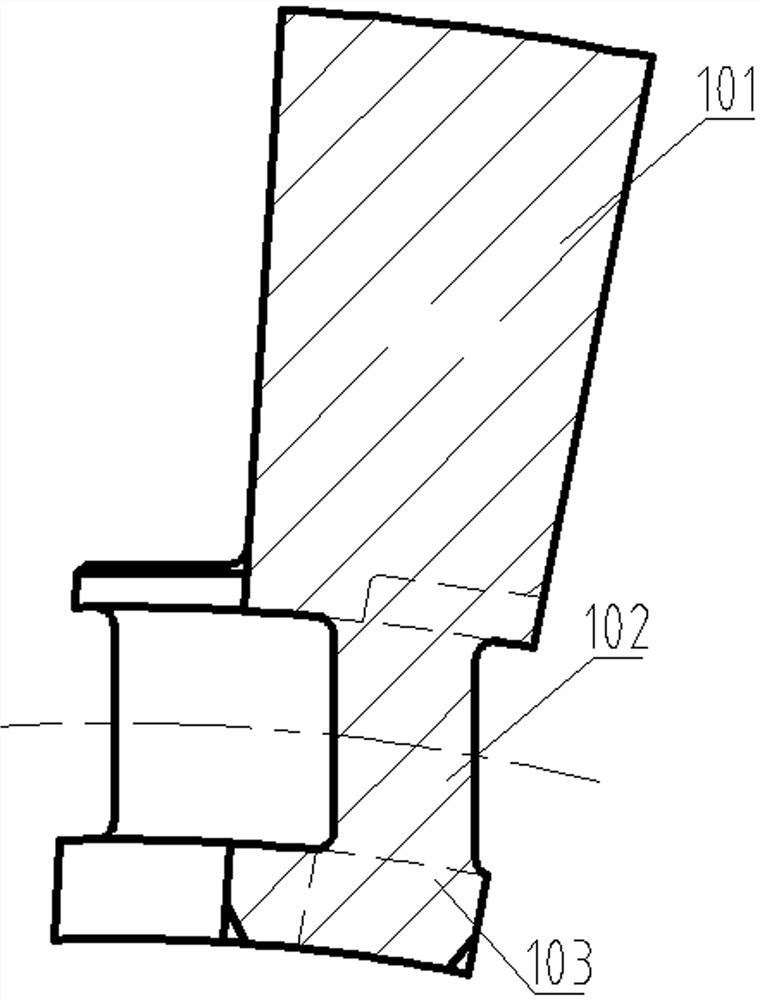

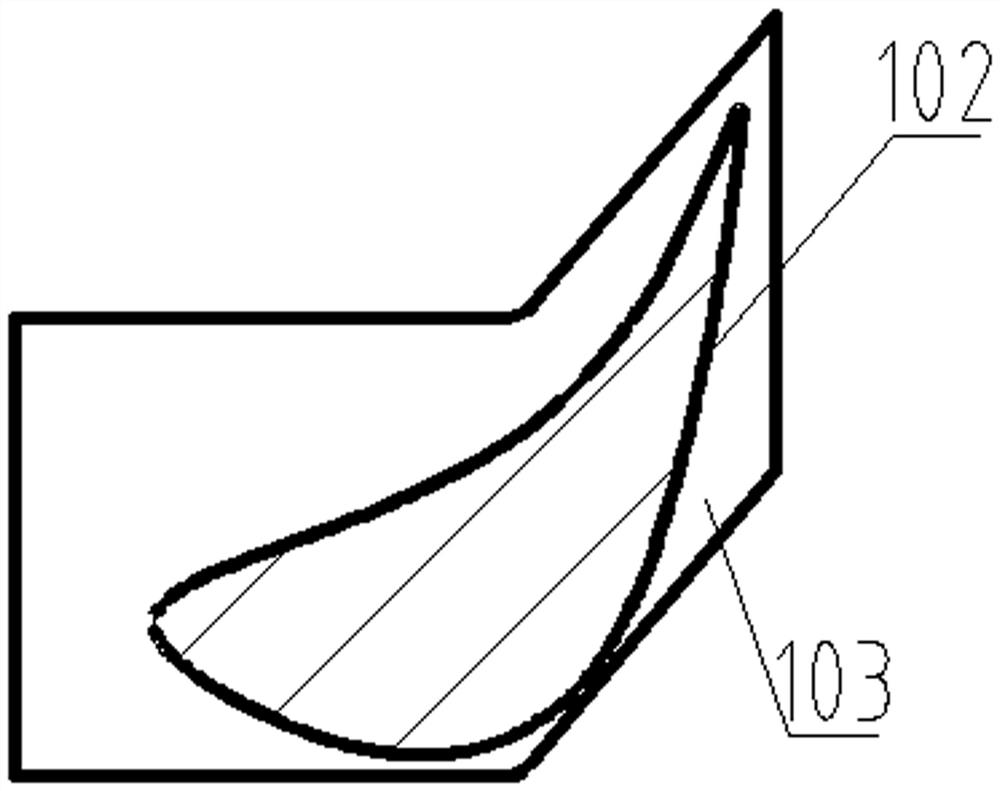

[0039] (2) Processing of stator blades: At least one end surface of the outer ring 101 of 46 stator blades 1 is provided with a positioning ring 5 corresponding to the positioning groove on the partition sleeve, and the circumferential assembly surface of each stator blade 1 is made by radiation The plane structure of the line; the air outlet side of the inner ring 103 of each stator blade 1 is provided with a machining allowance of 1mm, which is convenient for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com