Flame-retardant membrane and preparation method thereof

A technology of flame-retardant film and flame-retardant layer, which is applied in the field of flame-retardant film and its preparation, can solve problems such as limited use range, environmental pollution, and harm to human health, so as to shorten the production and manufacturing process, avoid environmental pollution, and reduce raw material costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

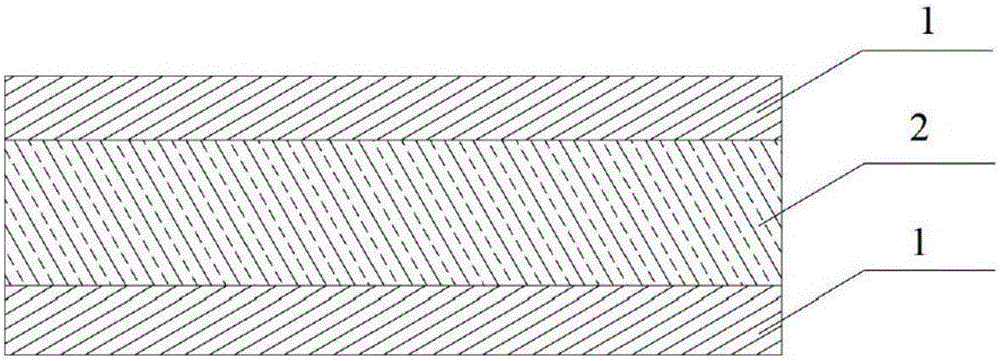

[0027] Such as figure 1 As shown, a flame retardant film includes: a PET substrate 2, a flame retardant layer 1 is provided on both sides of the PET substrate 2, the thickness of the flame retardant layer 1 is 10 μm, and the PET substrate 2 is PET Polyester film with a thickness of 20 μm.

[0028] 1) Get the following raw materials in parts by weight: 200 parts of polyester chips, 20 parts of zinc oxide, 0.2 part of decabromodiphenylethane, 4 parts of aluminum hydroxide, 3 parts of ammonium phosphate, 10 parts of polyvinyl alcohol (molecular weight 1000), 1 part of 2-carboxyethylphenylphosphinic acid, after being uniformly stirred by a mixer, pre-crystallized at 100°C for 5min, and dried in a dehumidifier at 150°C for 1h to obtain the raw material for the flame retardant layer;

[0029] 2) Take PET polyester film, pre-crystallize at 140°C for 10 minutes, and dry at 100°C for 1 hour to obtain PET polyester film raw material;

[0030] 3) 1) and 2) obtained flame-retardant laye...

Embodiment 2

[0035] Such as figure 1 As shown, a flame retardant film includes: a PET substrate 2, a flame retardant layer 1 is provided on both sides of the PET substrate 2, the thickness of the flame retardant layer 1 is 15 μm, and the PET substrate 2 is PET Polyester film with a thickness of 10 μm.

[0036] 1) Get the following raw materials in parts by weight: 150 parts of polyester chips, 20 parts of zinc oxide, 0.9 part of decabromodiphenylethane, 4 parts of aluminum hydroxide, 4 parts of ammonium phosphate, 5 parts of polyvinyl alcohol (molecular weight 10000), 5 parts of 2-carboxyethylphenylphosphinic acid, after being uniformly stirred by a mixer, pre-crystallized at 150°C for 5min, and dried in a dehumidifier at 200°C for 1h to obtain the raw material for the flame retardant layer;

[0037] 2) Take PET polyester film, pre-crystallize at 140°C for 10 minutes, and dry at 160°C for 5 hours to obtain PET polyester film raw material;

[0038] 3) 1) and 2) obtained flame-retardant la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com