Three-supporting surface prestress blocking seat mechanism of converter

A support surface, prestressing technology, applied in the direction of manufacturing converters, etc., can solve the problems of abnormal noise, stable and harmful converter operation, aggravated wear of contact support surface A, etc., to achieve enhanced stability, simple methods, and reduced maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

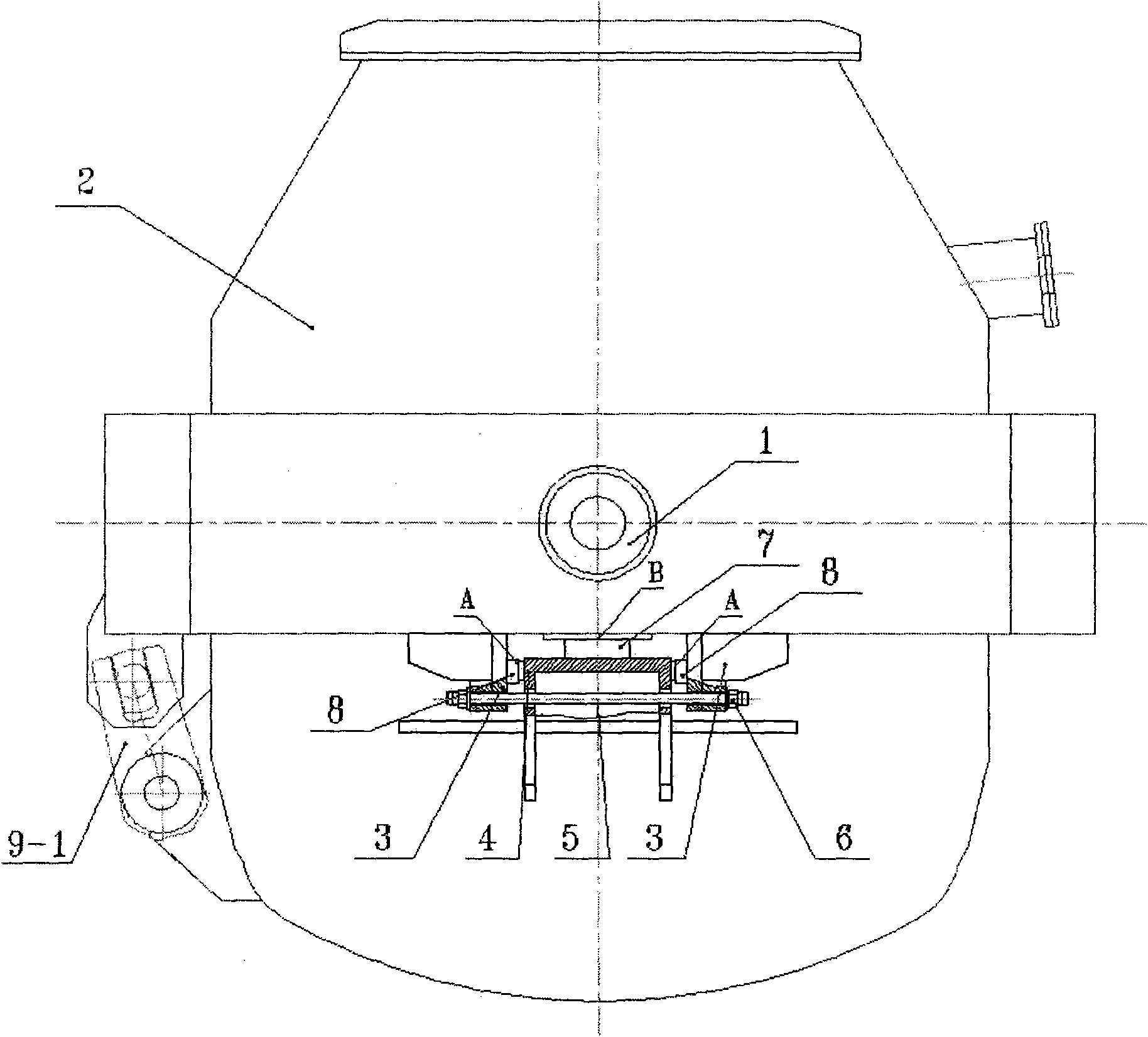

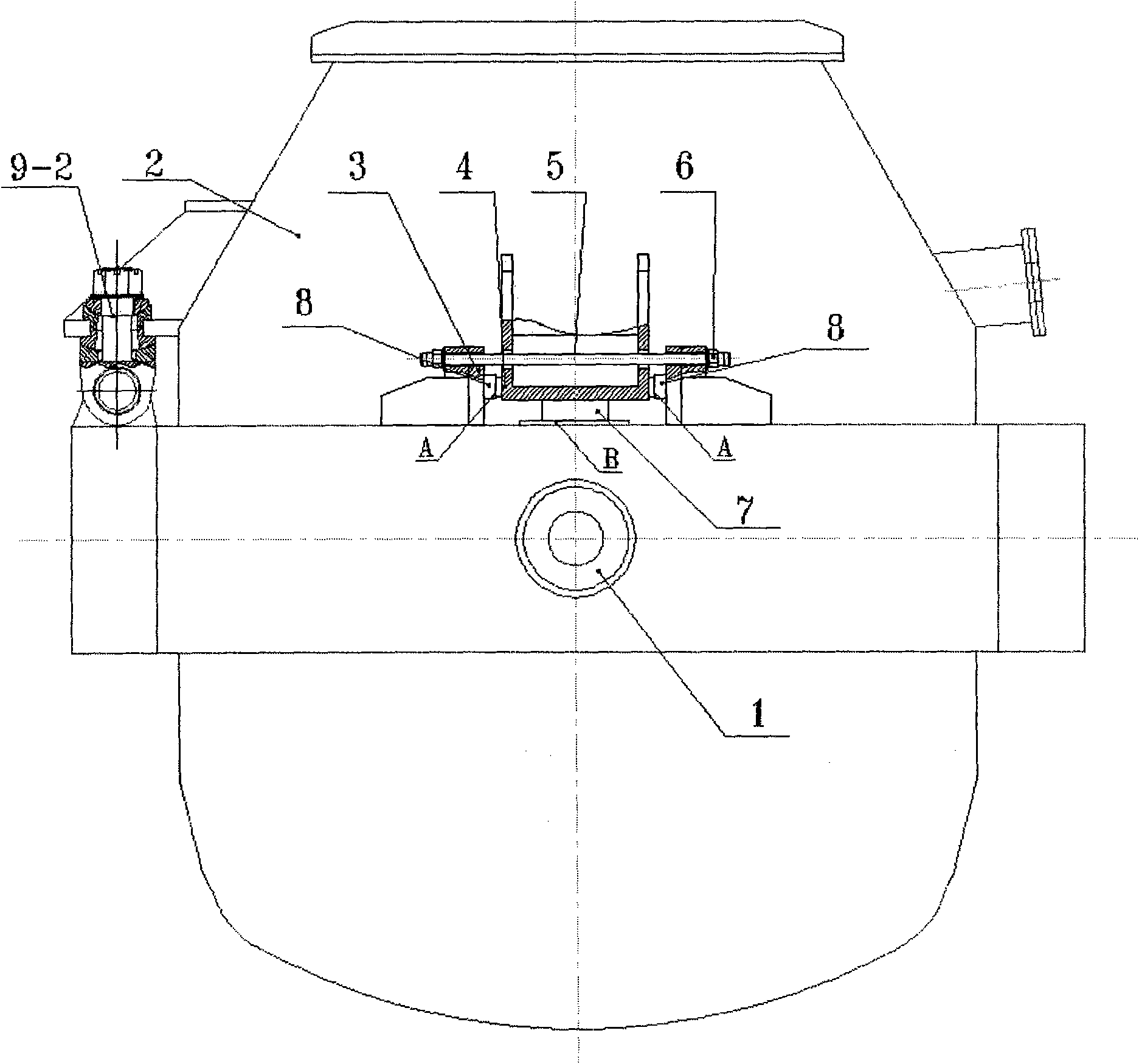

[0018] attached figure 2 It is the hanging embodiment of the present invention:

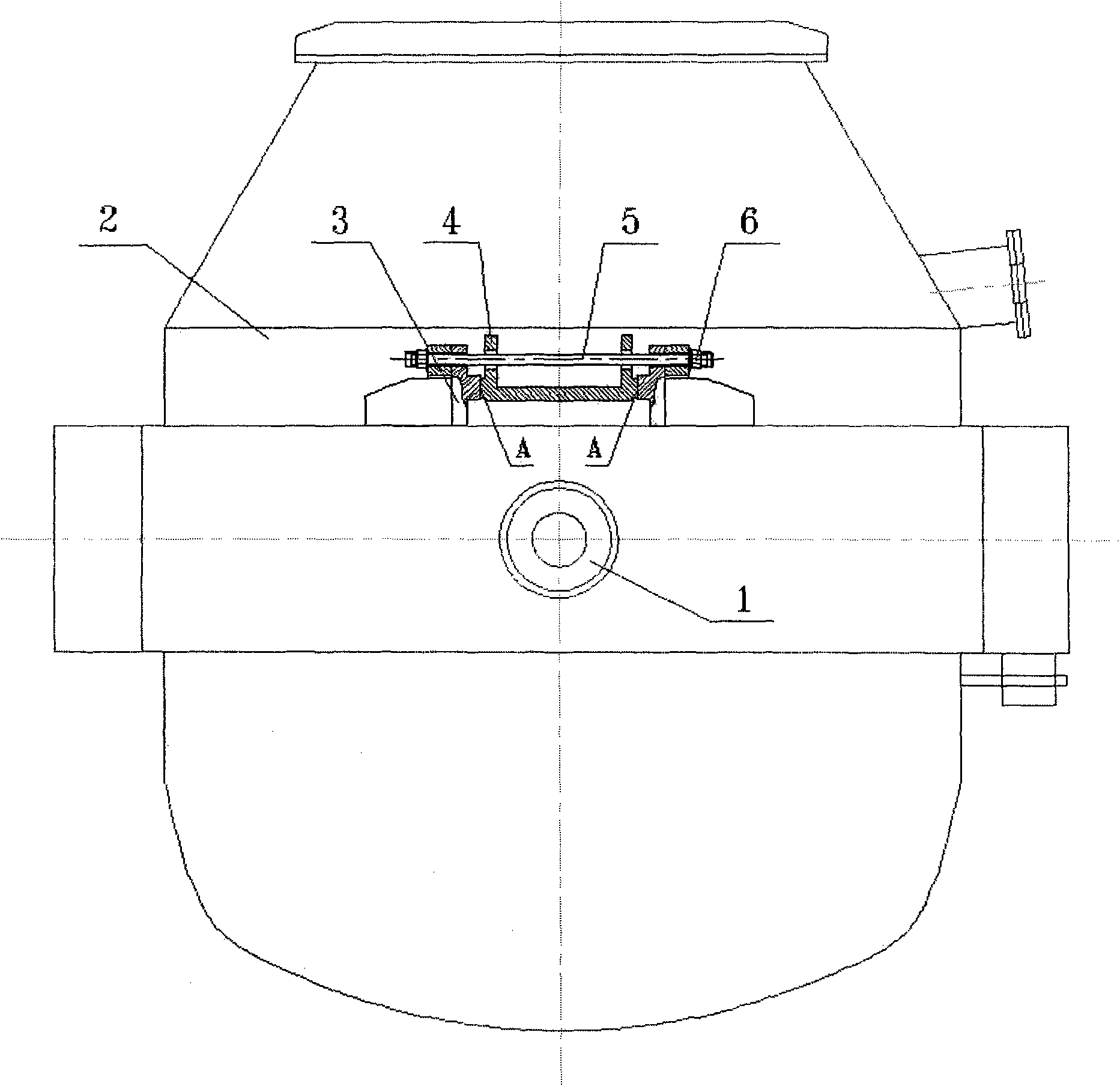

[0019] Each set of supporting ring and retaining seat mechanism: the supporting ring retaining seat 3 is welded on the supporting ring 1, the furnace shell seat 4 is welded on the furnace shell 2, and the upper part of the retaining ring retaining seat 3 on both sides is connected by a pre-tensioning rod 5 and a connecting member 6 , and tighten the nut to generate a certain pre-tightening force in the pre-tightening pull rod 5, the furnace shell seat 4 is clamped between the support ring and retaining seat 3, and there are two places between the furnace shell seat 4 and the retaining ring retaining seat 3 The side contact spacer 8, and the side contact support surface A is between the support ring block seat 3 and the furnace shell seat 4.

[0020] Between the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com