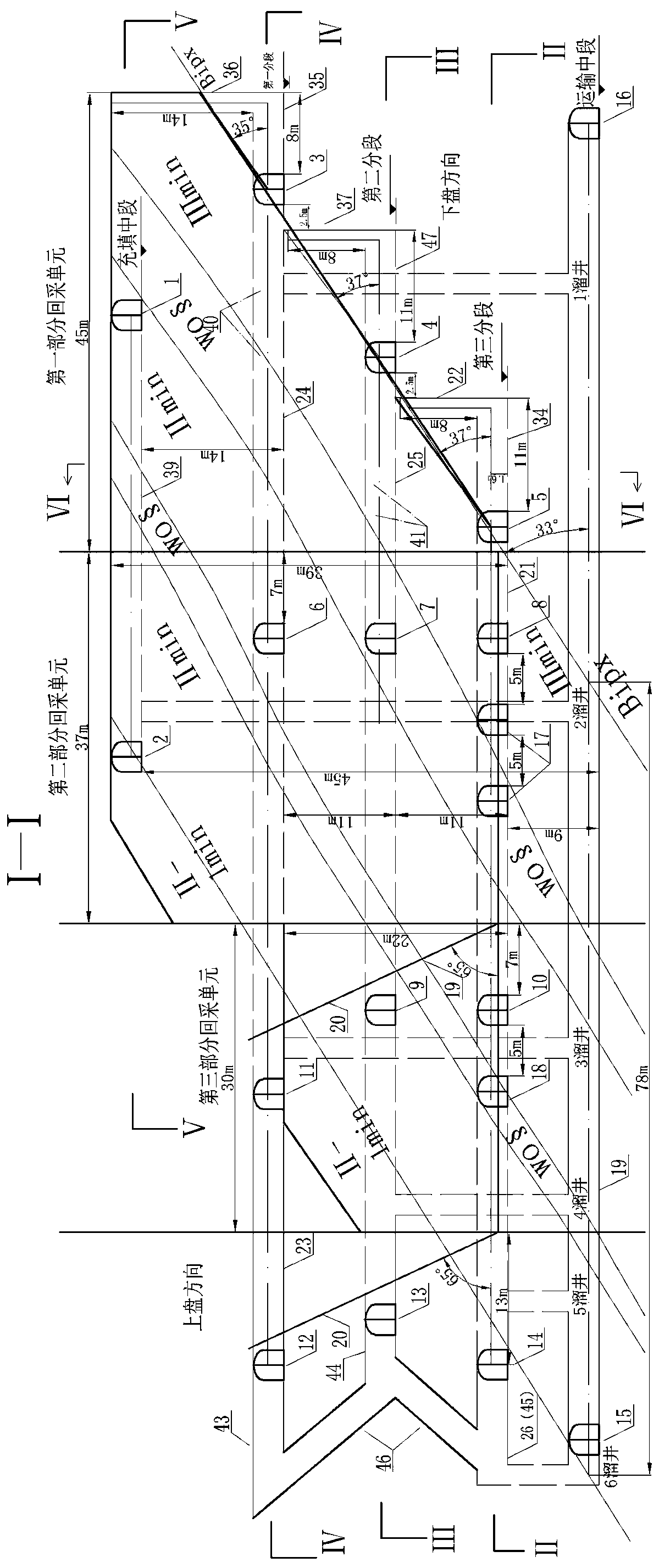

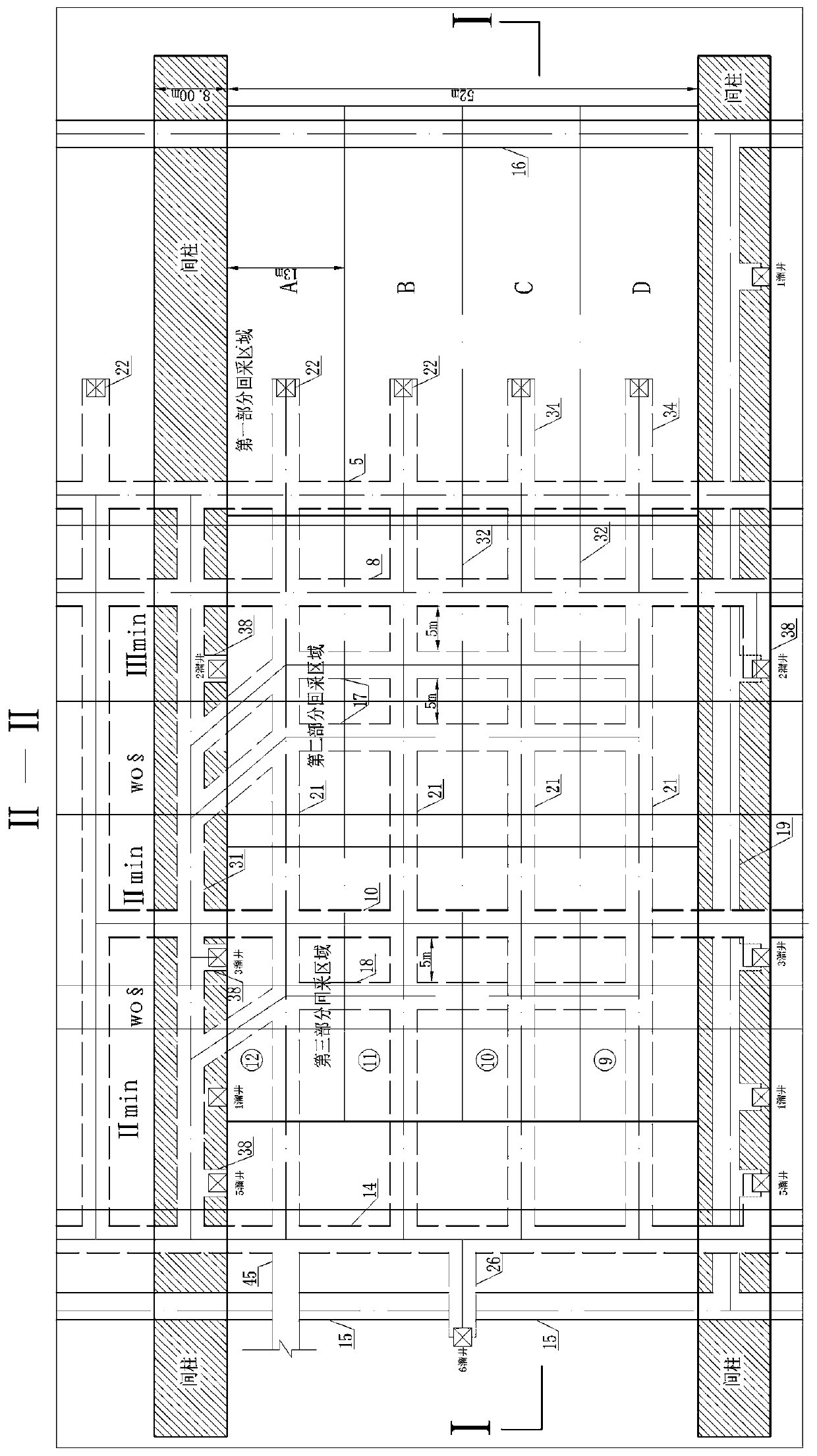

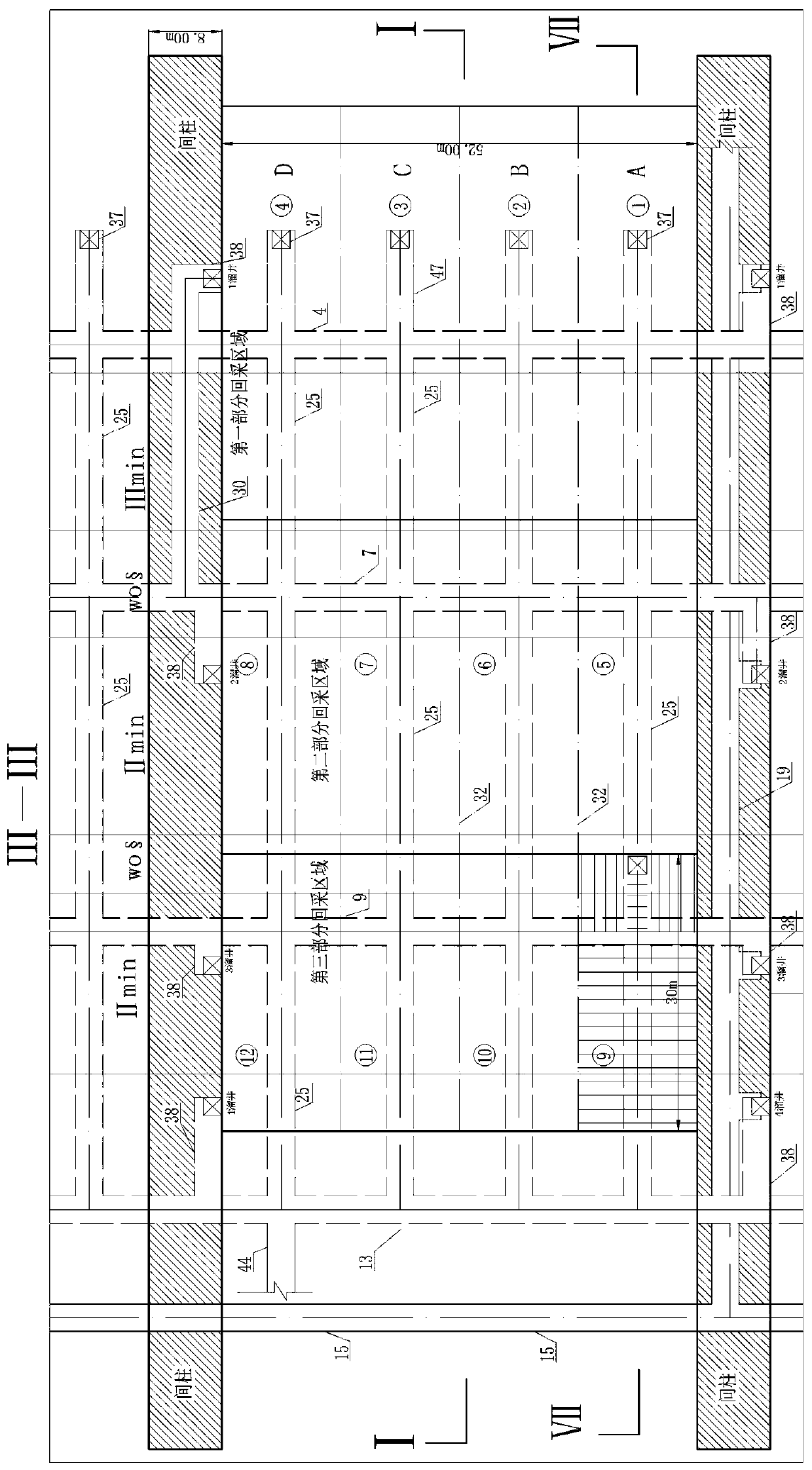

Flat bottom structure sublevel rock drilling stage ore removal subsequent cut-and-filling stoping method

A backfill mining method and segmented technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of low recovery rate, long mining and filling cycle time, and easy roof extraction in the room-and-pillar backfill mining method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] It is suitable for "three-under" mining bodies such as the overlying high-pressure aquifer of the ore body. The roof of the ore body is stable and the surrounding rock of the floor of the ore body is unstable. The ore body is moderately stable, with rocks between the ore body and the ore body. Soft and hard interbedded, with well-developed joints and fissures, with obvious layer-like structure, resulting in obvious differences in the mechanical strength of the ore body, rock inclusions and surrounding rocks of the roof and floor. It is suitable for ore bodies with a horizontal thickness greater than 40m and a long strike. The steeply inclined ore body with an inclination angle greater than 55°, and the friction force of the contact surface between the bottom wall of the ore body and the surrounding rock of the floor is relatively small, and the ore has good fluidity. The moving angle of the ore bottom wall is above 30° and the inclination angle is 30-55° Mining of metalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com