Rotary table with brake locking mechanism

A technology of locking mechanism and rotary table, which is applied in the field of rotary table, can solve the problems of difficult miniaturization, high equipment cost, and large space occupied by hydraulic equipment, and achieve the effect of equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

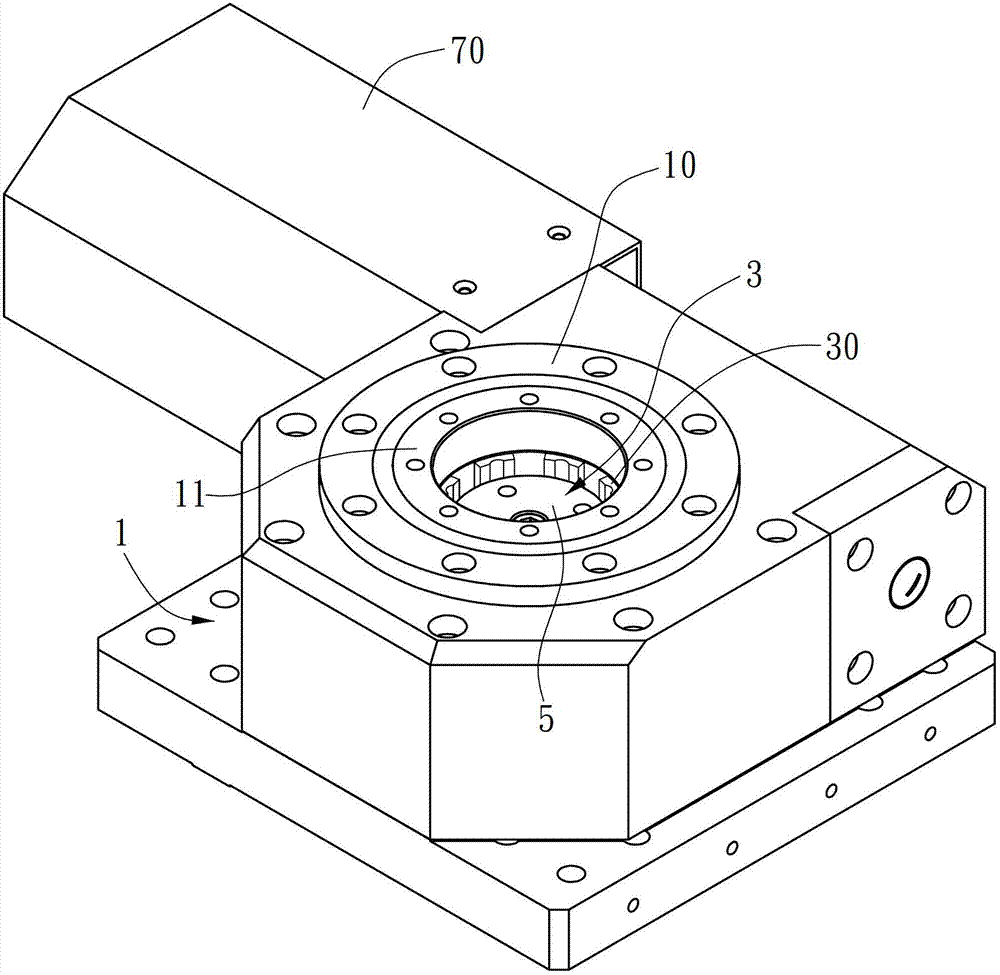

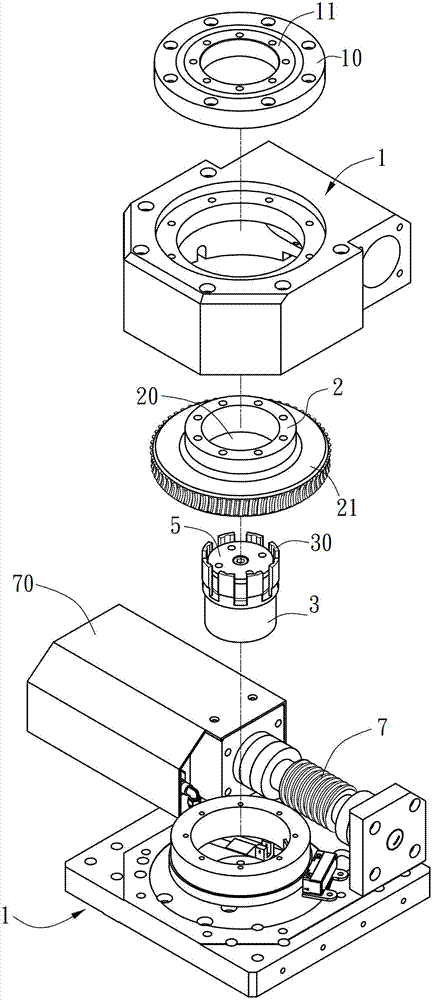

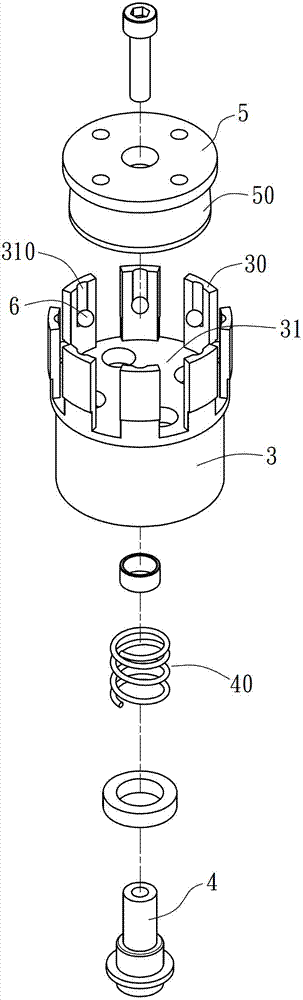

[0027] Please refer to Fig. 1 to Fig. 6, those shown in the figures are the selected embodiment structures of the present invention, which are for illustration purposes only, and are not limited by such structures in the patent application.

[0028] This embodiment provides a turntable with a brake locking mechanism. As shown in Figure 1, it is the structure of the turntable in this embodiment. It can be seen from Figure 2 and Figure 5 that the turntable in this embodiment is mainly in a body 1 A rotating shaft 2 is provided, and the rotating shaft 2 is driven to rotate in the body 1 by a driving member. The brake locking mechanism is set in the body 1 to brake the rotating shaft 2 .

[0029] The brake locking mechanism of the present invention, as shown in Fig. 1 to Fig. 5, includes a pneumatic cylinder 3, a piston rod 4, a follower 5 and several rolling parts 6, wherein:

[0030] As shown in Figures 1 to 2, in this embodiment, a positioning plate 10 is fixed on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com