Magnetic space-division oxygen-enriching device

A technology of oxygen enrichment and air separation, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve the effect of low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

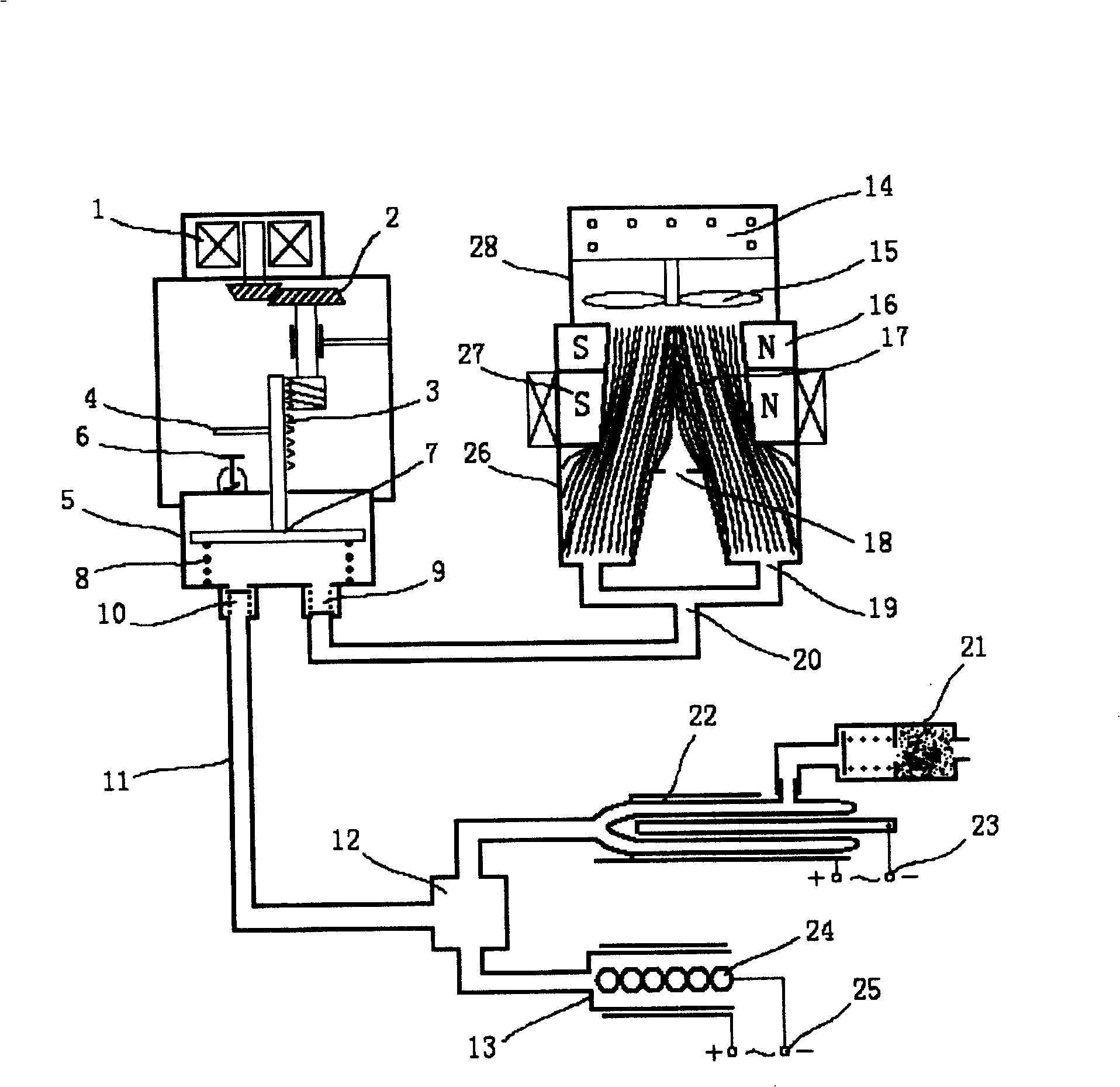

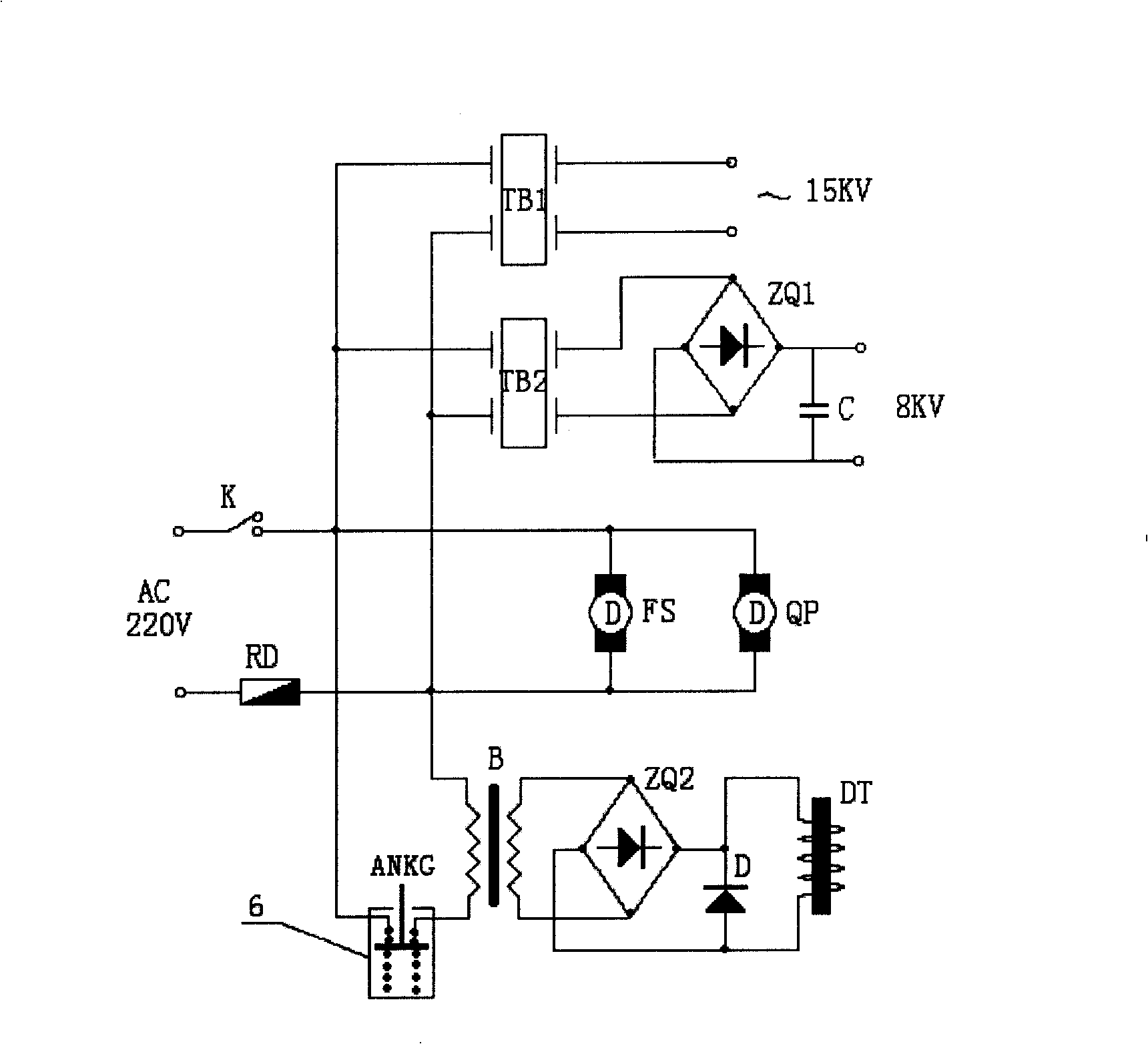

[0017] See figure 1 , the magnetic air separation and oxygen enrichment device comprises a cavity-shaped magnetic chamber 26, the magnetic chamber 26 is provided with an air inlet passage 28 and an air outlet passage 20, a fan 15 and an air filter cover 14 are set on the air inlet passage of the magnetic chamber 26, and the air outlet Passage 20 is connected with piston type air pump 5 with pipeline, and the periphery of magnetic chamber 26 is provided with electromagnet 27, and air exhaust port 18 is set at the rear section of magnetic chamber, and stainless steel wire 17 is filled in magnetic chamber 26 cavities, and electromagnet 27 is electrically connected with the magnetic control part 6, and the push-off switch of the magnetic control part 6 is located on the stroke of the piston type air pump piston 7.

[0018] figure 1 The shown device is a magnetic air separation and oxygen enrichment multifunctional device adopting the magnetic air separation and oxygen enrichment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com