Organic light emitting device

A technology of organic light-emitting devices and light-emitting layers, which is applied in lighting devices, electroluminescent light sources, organic semiconductor devices, etc., and can solve the problems of unsatisfactory connection voltage, luminous efficiency, and life properties of organic light-emitting devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

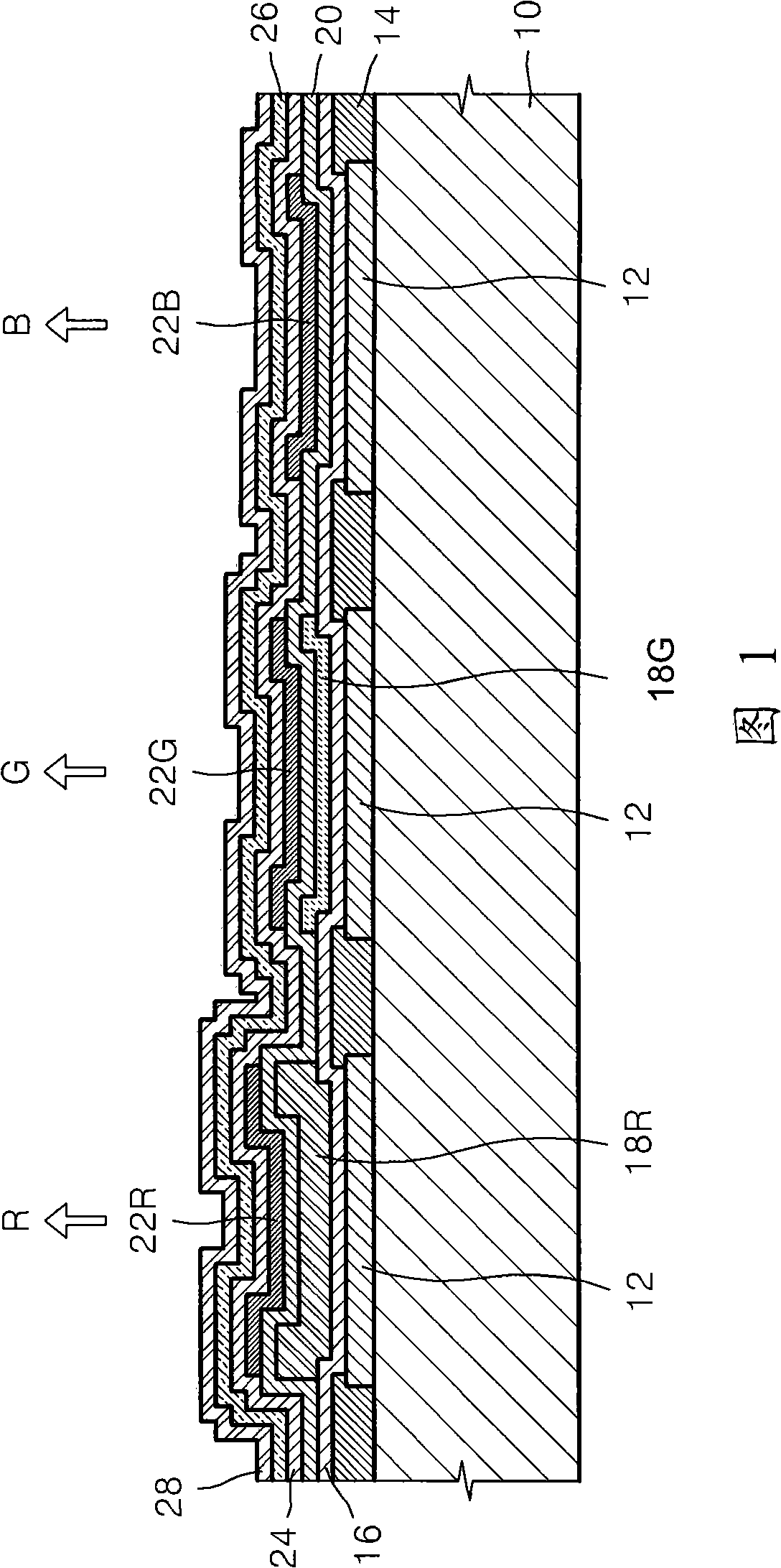

[0020] FIG. 1 is a schematic cross-sectional view of an organic light emitting device according to an embodiment of the present invention.

[0021] Referring to FIG. 1 , the organic light emitting device includes a substrate 10 , a first electrode 12 , a hole injection layer 16 and respectively patterned red light emitting layers 22R, green light emitting layers 22G and blue light emitting layers 22B. The first auxiliary layer 18R is disposed between the hole injection layer 16 and the red light emitting layer 22R to adjust the resonance period of red light. The second auxiliary layer 18G is disposed between the hole injection layer 16 and the green light emitting layer 22G to adjust the resonance period of green light. The hole transport layer 20 is arranged at the lower portion of the red light emitting layer 22R, the green light emitting layer 22G, and the blue light emitting layer 22B. The electron transport layer 24 , the electron injection layer 26 and the second electr...

Embodiment 1

[0081] 15Ω / cm 2 (1200 ) The ITO glass substrate was cut into a size of 50mm×50mm×0.7mm as an anode, and was washed with isopropanol and pure water by microwave for 5 minutes respectively. The ITO glass substrate was irradiated with ultraviolet rays for 30 minutes and washed with ozone, and then installed in a vacuum deposition apparatus.

[0082] A hole injection material (product name: LHT-001) purchased from LUDIS was vacuum deposited onto the glass substrate to form a hole injection layer with a thickness of 130 nm. Then, a hole transport material (product name: IDE-406) purchased from Idemitsu Corporation was vacuum-deposited to form a first auxiliary layer with a thickness of 80 nm. Then vacuum-deposit 4,4'-bis[N-(1-naphthyl)-N-phenylamino]biphenyl (NPB) on the first auxiliary layer to form a hole transport layer with a thickness of 20 nm.

[0083] Known red phosphorescent host material GDI1403 and known red phosphorescent dopant Ir(piq) available from Gracel 3 (dopi...

Embodiment 2

[0086] An organic light-emitting device was prepared in the same manner as in Example 1, except that HTM016 from Merck was used instead of IDE406 from Idemitsu in the process of forming the first auxiliary layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com