Electrospinning direct-writing nozzle capable of controlling starting and stopping

An electrospinning direct writing, start-stop control technology, applied in the direction of spraying device, spraying device, liquid spraying equipment, etc., can solve the problems of inability to obtain fine nanofibers, high turn-on voltage, difficult direct writing of complex patterns, etc., to achieve good Effects of positioning and spray consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

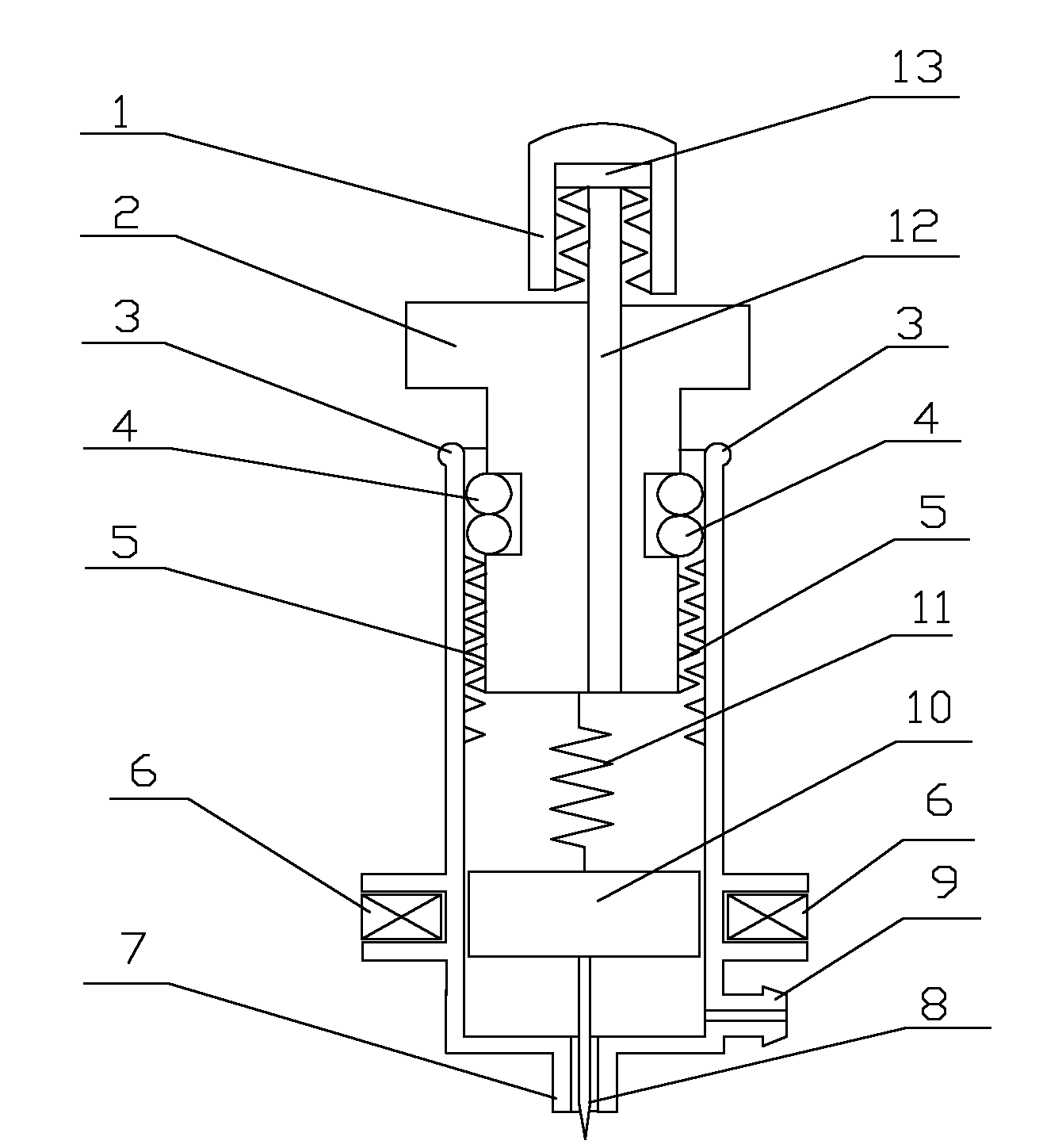

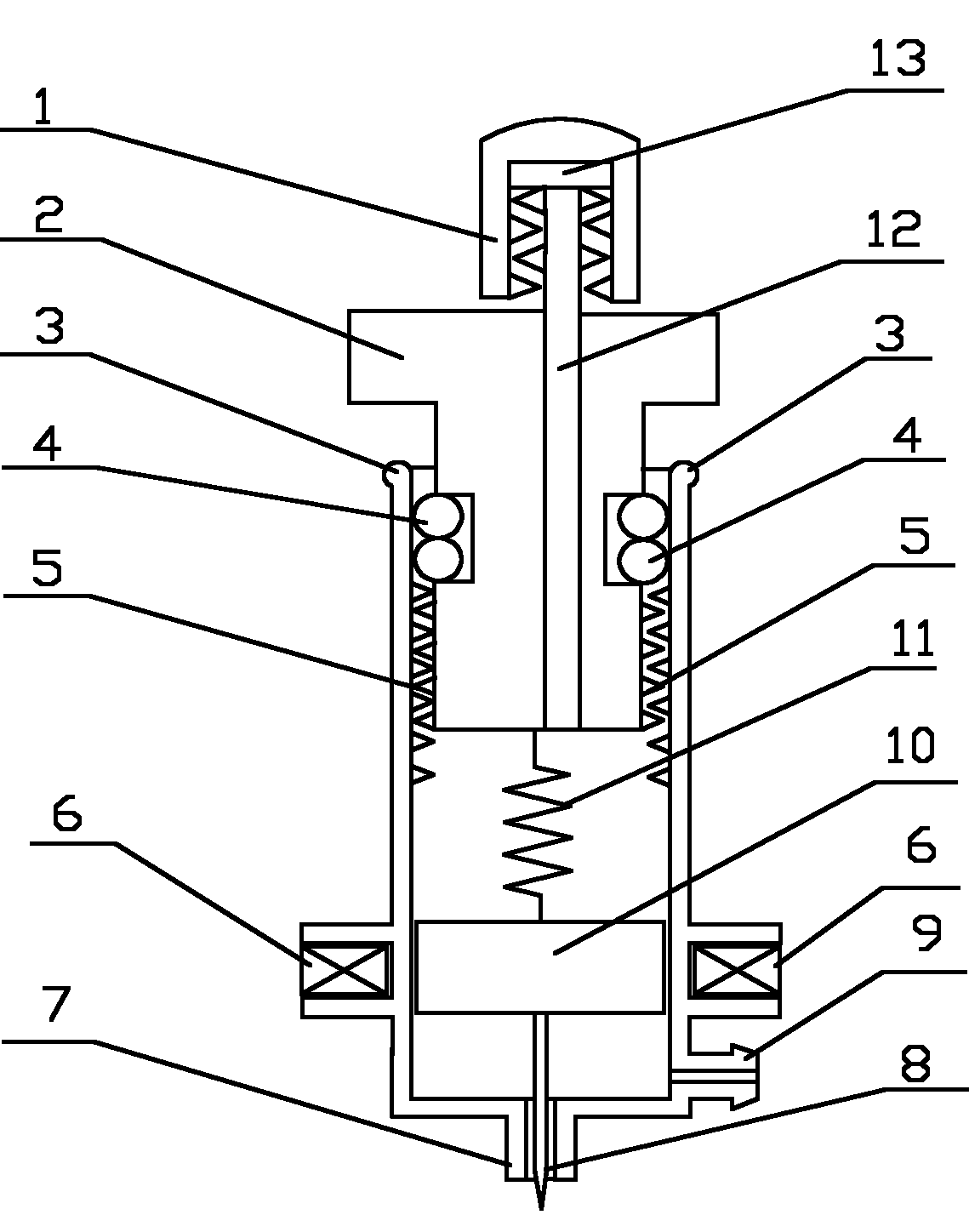

[0022] see figure 1 , The embodiment of the present invention is provided with a hollow casing with a nozzle 3, a threaded adjustment plug 2, a coil 6, an armature 10, a return spring 11, a probe 8, an exhaust pipe 12, a sealing cap 1 and a gasket 13. The front end of the hollow sleeve 3 with a nozzle is provided with a nozzle hole 7 and an injection hole 9, and the threaded adjustment plug 2 is arranged at the rear end of the hollow sleeve 3 with a nozzle, and is screwed to the hollow sleeve 3 with a nozzle through a fine thread 5 and sealed. Ring 4 is sealed. The coil 6 is set on the outer side of the hollow casing 3 with a nozzle, and the armature 10 is arranged in the hollow casing 3 with a nozzle and can move up and down. The probe 8 is fixedly connected with the armature 10, the front end of the probe 8 is located in the nozzle hole 7, the rear end of the probe 8 is fixedly connected with one end of the return spring 11, and the other end of the return spring 11 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com