Dual-layer perovskite light emitting diode and preparation method therefor

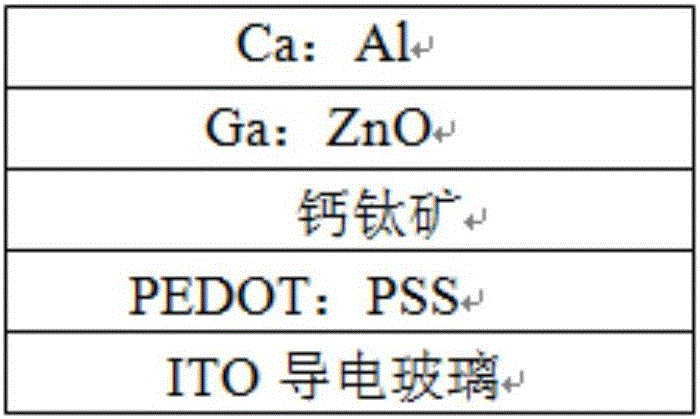

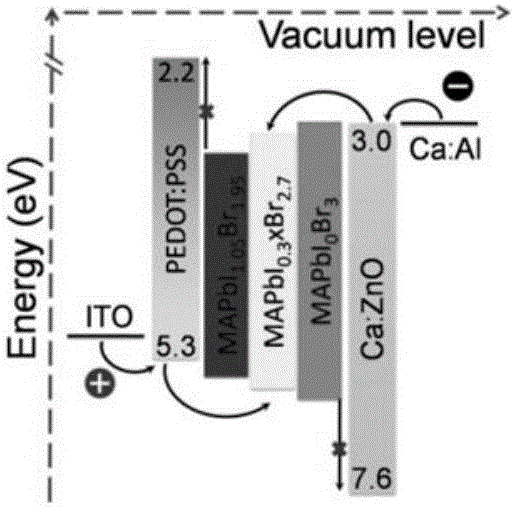

A technology of light-emitting diodes and double-layer perovskites, which is applied in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, can solve problems such as unfavorable electron transmission, energy waste, and heat loss, and achieve improved luminous efficiency and reduced Turn-on voltage and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

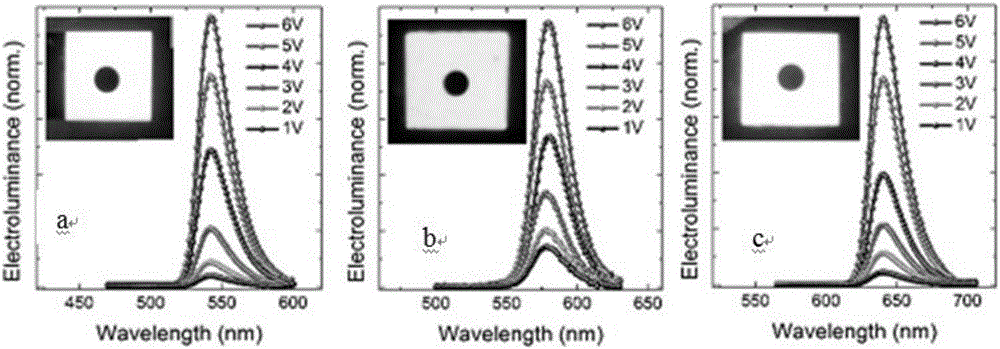

[0042] CH 3 NH 3 PbBr 3 The precursor solution was diluted to a mass ratio of 1.25% to obtain a green light-emitting perovskite solution, and the photoluminescence spectrum of the prepared light-emitting diode was as follows: image 3 as shown in a.

Embodiment 2

[0044] The CH with a mass ratio of 2.5% 3 NH 3 PB 3 and CH at a mass ratio of 1.25% 3 NH 3 PbBr 3 The perovskite precursor solutions of two different systems were mixed according to the molar ratio of 0.3:2.7 to obtain a yellow-emitting perovskite solution. The photoluminescence spectrum of the prepared light-emitting diode was as follows: image 3 As shown in b.

Embodiment 3

[0046] The CH with a mass ratio of 2.5% 3 NH 3 PB 3 and CH at a mass ratio of 1.2% 3 NH 3 PbBr 3 The perovskite precursor solutions of two different systems are mixed according to the molar ratio of 1.05:1.95 to obtain a red-emitting perovskite solution. The photoluminescence spectrum of the prepared light-emitting diode is as follows: image 3 as shown in c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com