Quantum dot light emitting diode and manufacturing method thereof

A quantum dot light-emitting and diode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor device performance, unmodified electron transport layer, unstable dopant, etc., to reduce refraction Efficiency imbalance, improving light extraction efficiency, and reducing the effect of total light reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

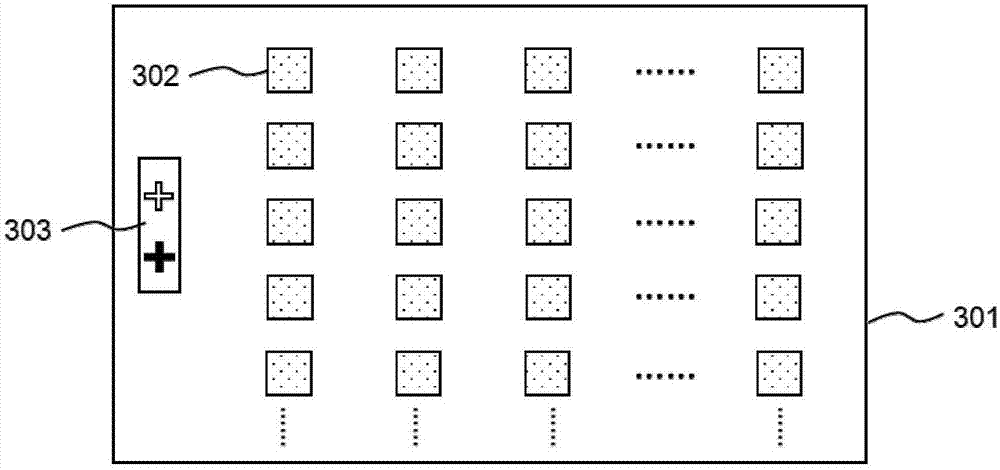

[0055] In one embodiment, the imprint template adopts soft polydimethylsilane (PDMS), and the shape of the nano-concave-convex structure is as follows: Figure 4 As shown, the period is preferably 400nm, the groove depth is 50nm, and the duty ratio is 0.6.

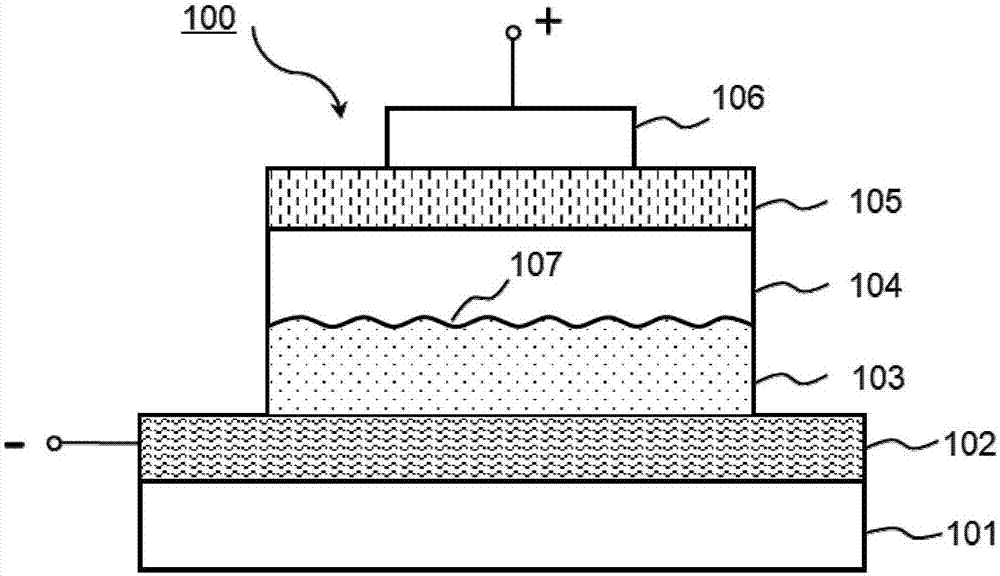

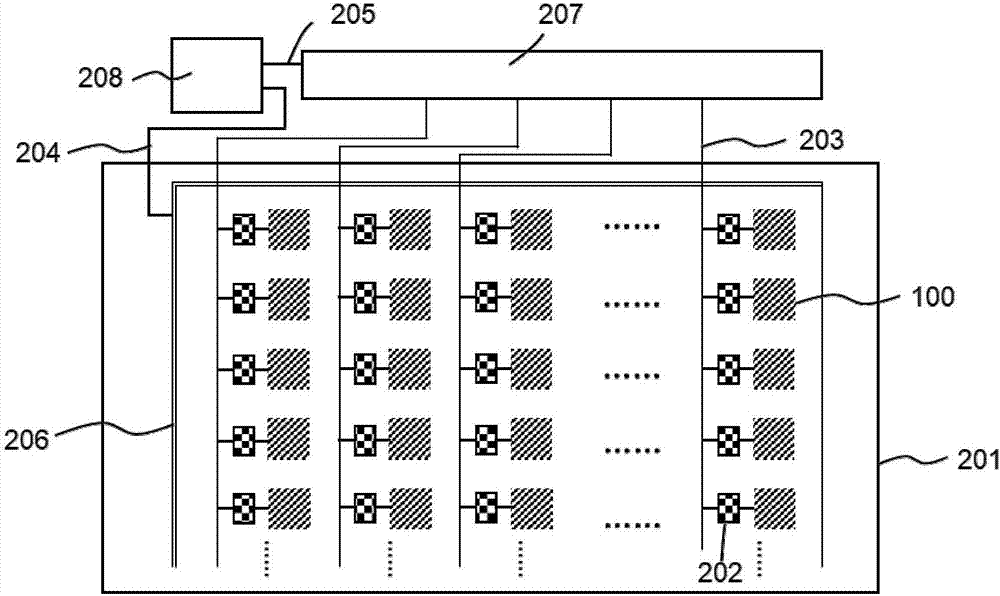

[0056] A quantum dot light-emitting diode with a nano-light extraction structure, including an ITO transparent cathode on a substrate, a ZnO electron transport layer, a CdSe / ZnS quaternary gradient alloy quantum dot light-emitting layer, and a PVK / PEDOT:PSS composite hole transport layer and Al metal anode, the specific manufacturing process of each layer structure is preferably a method such as solution method spin coating, vacuum thermal evaporation, or other known methods. Preferably, in this embodiment, the specific process of device manufacturing is as follows:

[0057] (1) Substrate and cathode cleaning: After the ordinary float glass substrate substrate is cleaned with detergent, a patterned ITO film is sputtered on...

Embodiment 2

[0064] A quantum dot light-emitting diode with an electron transport layer modification layer, including an ITO transparent cathode on a substrate, a ZnO electron transport layer, a PEI modification layer, a CdSe / ZnS quaternary gradient alloy quantum dot light-emitting layer, PVK / PEDOT:PSS Composite hole transport layer and Al metal anode, the specific manufacturing process of each layer structure is preferably solution method spin coating, vacuum thermal evaporation and other methods, or other known methods. Preferably, in this embodiment, the specific process of making quantum dot light-emitting diodes as follows:

[0065] (1) Substrate and cathode cleaning: same as in Embodiment 1.

[0066] (2) Preparation of ZnO precursor solution: same as Example 1.

[0067] (3) Fabrication and modification of the electron transport layer: Spin-coat a layer of ZnO precursor solution on the substrate treated in step (1) in air. The control speed is 4000rpm, the time is 60s, and annealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com