Hydrophilic polyvinyl chloride alloy ultrafiltration membrane and production method thereof

A polyvinyl chloride and ultrafiltration membrane technology, applied in the field of membrane separation, can solve the problems of decreased separation performance, loss of hydrophilicity, unstable structure, etc., to achieve improved hydrophilicity, increased surface self-assembly, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

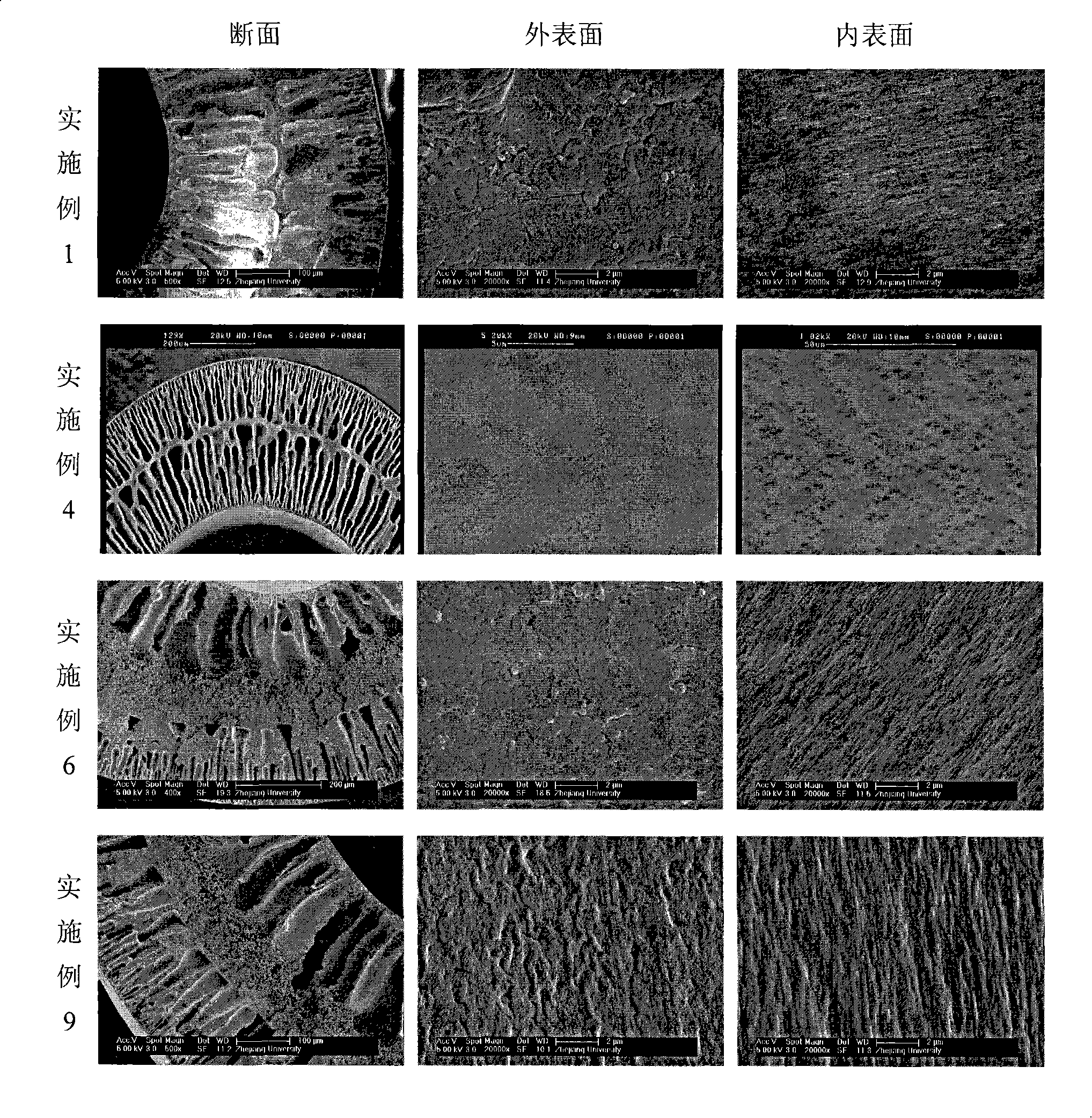

Examples

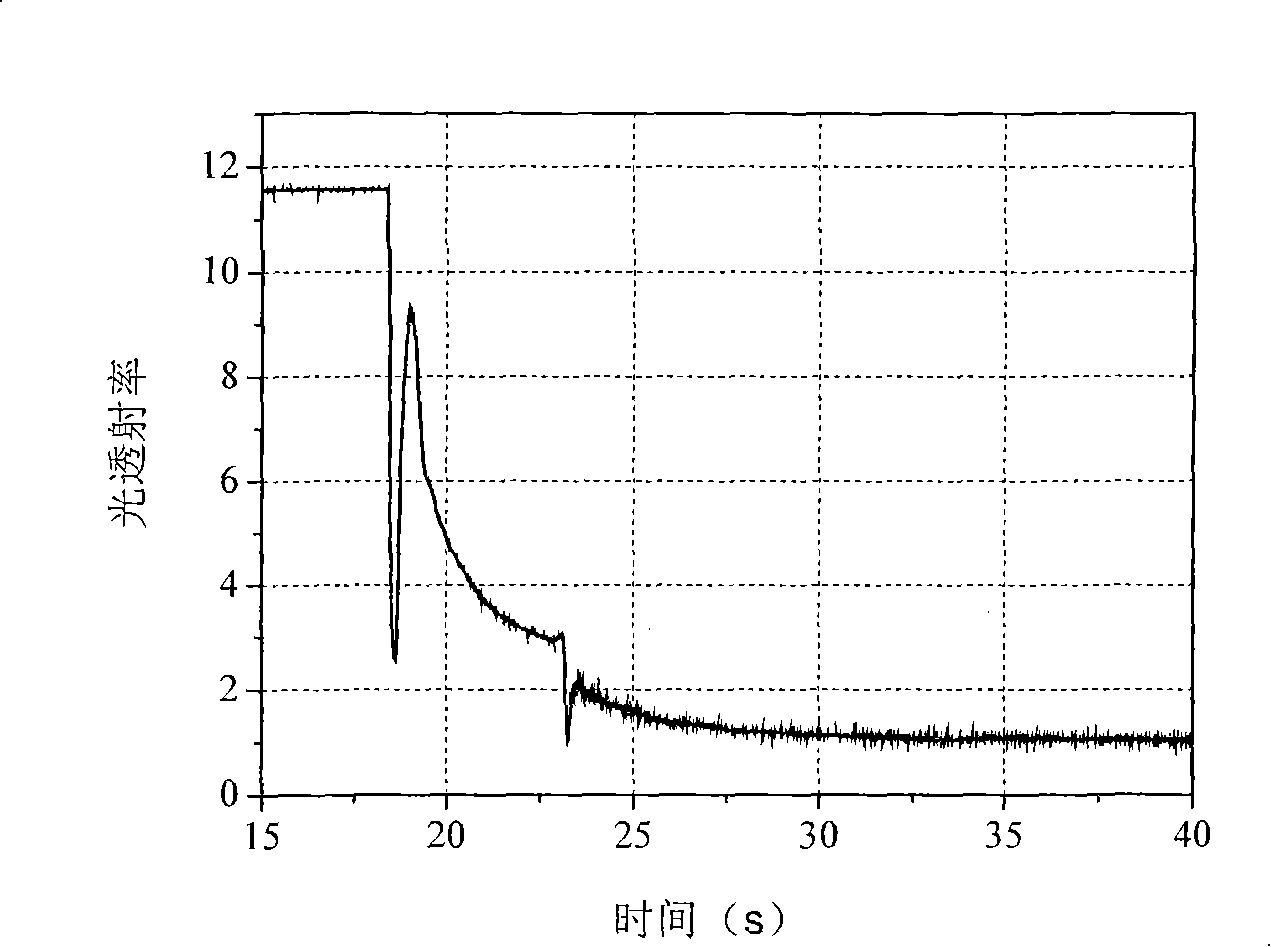

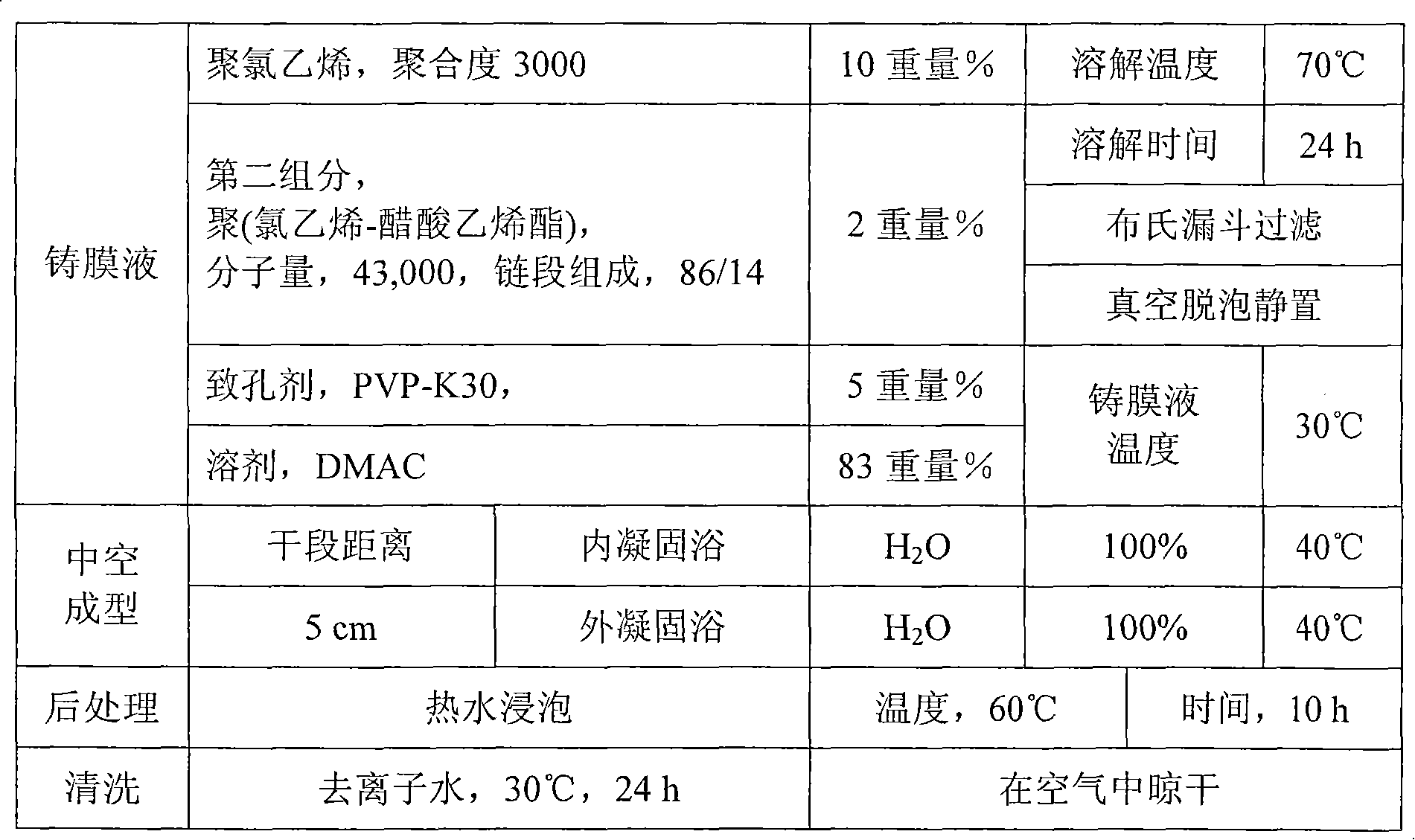

Embodiment 1

[0047] Polyvinyl chloride / poly(vinyl chloride-vinyl acetate) / PVP / H with a weight ratio of 10 / 2 / 5 / 0.5 / 82.5 2 O / DMAc was fully stirred in the flask at 70°C for 24 hours until the polymer was completely dissolved and a uniform and transparent solution was obtained. The above-mentioned casting solution was filtered with a Buchner funnel, then subjected to vacuum degassing, and left to stand for use. After the casting solution is sprayed from the spinneret of the spinning machine, it stays in the air at room temperature with a humidity of 80% for 10 seconds, and then immersed in a pure water coagulation bath at 60°C at a constant speed, and the film after gel solidification is taken out and immersed in 30°C NaOH solution for 24h, followed by deionized cleaning at 40°C for 10h, and finally air-dried to obtain a hydrophilized PVC alloy ultrafiltration membrane.

[0048]

[0049] The contact angle, porosity, water flux and BSA rejection rate of the prepared PVC alloy ultrafiltrati...

Embodiment 2

[0051] The preparation steps are the same as in Example 1.

[0052]

Embodiment 3

[0054] The preparation steps are the same as in Example 1.

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com