Developing degradable polymer stent and preparation method thereof

A technology for degrading polymers and developers, which is applied in the field of medical devices, can solve the problems of easy peeling of coatings, low grafting rate of iodine atoms, and disappearance, so as to improve surface hydrophilicity, reduce material surface energy, and improve binding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

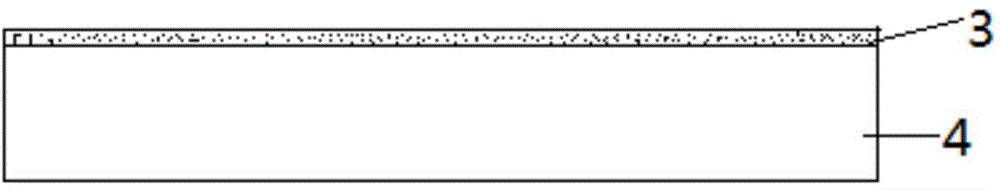

[0040] Refer to attached figure 1 As shown, raw materials: PLLA degradable cardiovascular stent (BVS), developing coating (PLGA9%wt, iopromide1%wt, 90%wt alcohol)

[0041] Production process: First, use a plasma cleaning machine to treat the surface of the bracket with oxygen plasma (plasma treatment requirements: at 25°C, the power is 70KHz, the pressure in the working cabin is 0.01atm-0.3atm during cleaning, and the processing time Then put it into the plasma coating equipment, the temperature in the plasma coating cabin must be controlled at 20°C (process requirements: the power is 40KHz, nitrogen is used as the carrier gas, and the pressure in the working cabin is 0.01atm- 0.3atm, the processing time is 20min), and the developing coating (thickness is 0.5μm) is prepared.

[0042] After oxygen plasma treatment on the surface 4 of the stent substrate, the hydrophilic ability is greatly improved, and the affinity with the developing coating achieves a good effect.

Embodiment 2

[0044] Refer to attached figure 1 As shown, production raw materials: PLLA degradable cardiovascular stent (BVS), developing coating (collagen 9% wt, diatrizoate meglumine 1% wt, 75% wt alcohol)

[0045] Production process: First, use anodic pulse equipment to anodize the surface of the BVS stent (hydrochloric acid solution with an electrolyte mass fraction of 35%, time 10min, current 0.05A, frequency 1000Hz); then put it into the plasma coating equipment, The temperature in the plasma coating cabin must be controlled at 50°C (process requirements: the power is 40KHz, nitrogen is used as the carrier gas, the pressure in the working cabin is 0.01atm -0.3atm during cleaning, and the processing time is 20min), and the developing coating is prepared. (thickness is 2 μm).

[0046] After the surface 4 of the stent substrate is anodized, the hydrophilic ability is greatly improved, and the affinity with the developing coating is better. The prepared developing coating 3 has good af...

Embodiment 3

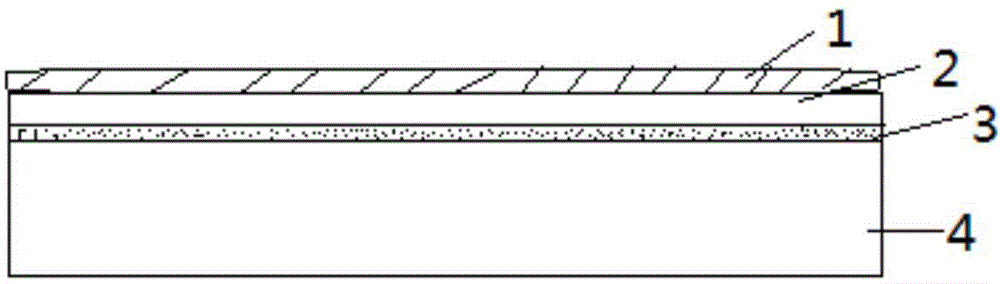

[0048] Refer to attached figure 2 As shown, production raw materials: PLLA degradable cardiovascular stent (BVS), developing coating (PLLA9%wt, iohexol 1%wt, 50%wt alcohol), protective coating (PDLA0.5%wt, dichloromethane 99.5%), drug coating (PLGA 1%, rapamycin 1%, dichloromethane 98%)

[0049] Production process: First, use a plasma cleaning machine to treat the surface of the bracket with oxygen plasma (plasma treatment requirements: at 45°C, the power is 30KHz, the pressure in the working cabin is 0.01atm -0.3atm during cleaning, and the processing time Then put it into the plasma coating equipment, the temperature inside the plasma coating chamber must be controlled at 30°C (process requirements: the power is 40KHz, argon is used as the carrier gas, and the pressure in the working chamber is 0.01atm during cleaning -0.3atm, treatment time is 20min), prepare developing coating (thickness is 0.5μm); after the developing coating is dry, use coating machine to apply protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com