Fabricating method of fiber powder modified polymer microporous film

A powder modification and polymer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of easy agglomeration of inorganic nanoparticles, and achieve low preparation cost, less addition, and variety many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

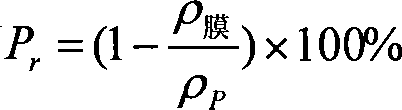

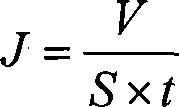

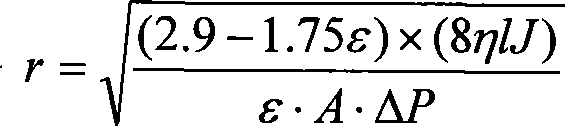

[0043] Take 0.5g of the washed hydrophobic polyester and acrylic fiber, the average particle diameters of the two fiber powders are 72.82 μm and 91.98 μm respectively), put them into two round bottom flasks respectively, and add 79.7g of solvent DMAc. Mix them thoroughly in the flask, and disperse them in an ultrasonic oscillator for 5 hours at a temperature of 25°C. Then add 9.3g of polyvinylidene fluoride, 3.0g of polyvinylpyrrolidone, 4.5g of deionized water and 3.0g of 1,2-propanediol to the two solutions, seal and stir at a constant temperature under an electric stirrer at a temperature of 70°C , the time is 24h. Then scrape the four casting solutions, scrape the casting solution on the glass plate with a scraper to form a solution film with a thickness of 300 μm, let it stand in the air for 5 seconds, and then immerse it in a deionized water coagulation bath at 25°C for 10 minutes Finally, the membrane was removed from the coagulation bath and immersed in deionized wate...

specific Embodiment 2

[0046] Take 0.5g each of the cleaned hydrophobic vinylon and viscose fiber powders. The average particle diameters of the two fiber powders are 92.04μm and 81.93μm respectively, and put them into two round bottom flasks respectively, and add 79.7g of solvent DMAc . Mix them thoroughly in the flask, and disperse them in an ultrasonic oscillator for 5 hours at a temperature of 25°C. Then add 9.3g of polyvinylidene fluoride, 3.0g of polyvinylpyrrolidone, 4.5g of deionized water and 3.0g of 1,2-propanediol to the two solutions, seal and stir at a constant temperature under an electric stirrer at a temperature of 70°C , the time is 24h. Then scrape the four casting solutions, scrape the casting solution on the glass plate with a scraper to form a solution film with a thickness of 300 μm, let it stand in the air for 5 seconds, and then immerse it in a deionized water coagulation bath at 25°C for 10 minutes Finally, the membrane was removed from the coagulation bath and immersed in...

specific Embodiment 3

[0049]Take 0.5g of washed natural protein fiber wool and down, with average particle sizes of 53.45μm and 61.16μm, respectively, and put them into two round bottom flasks, and add 79.5g of solvent DMF. Mix them thoroughly in the flask, and disperse them in an ultrasonic vibration dish for 4 hours at a temperature of 25°C. Add 15.0g polyvinylidene fluoride (PVDF, Shanghai 3F New Material Co., Ltd., model is FR904), 5.0g polyethylene glycol 6000 to four kinds of solutions afterwards, seal, carry out constant temperature stirring under electric stirrer, temperature control At 40° C. for 48 hours, filter and vacuum defoam the membrane-forming solution prepared above. Then scrape the four kinds of casting solutions, and use a scraper to scrape the casting solution on the glass plate to form a solution film with a thickness of 300 μm. After standing in the air for 5 seconds, immerse in a deionized water coagulation bath at 25 ° C for 10 minutes. Finally, the membrane was removed fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com