Total tanshinone composite preparation

A technology of compound preparation and total tanshinone, which is applied in the directions of antidote, pill delivery, drug combination, etc., can solve the problems of not comprehensively considering the effective components of tanshinone, low oral bioavailability of tanshinone, unsatisfactory absorption of tanshinone, etc., and achieves a control method. Convenience, improved bioavailability, enhanced metabolic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

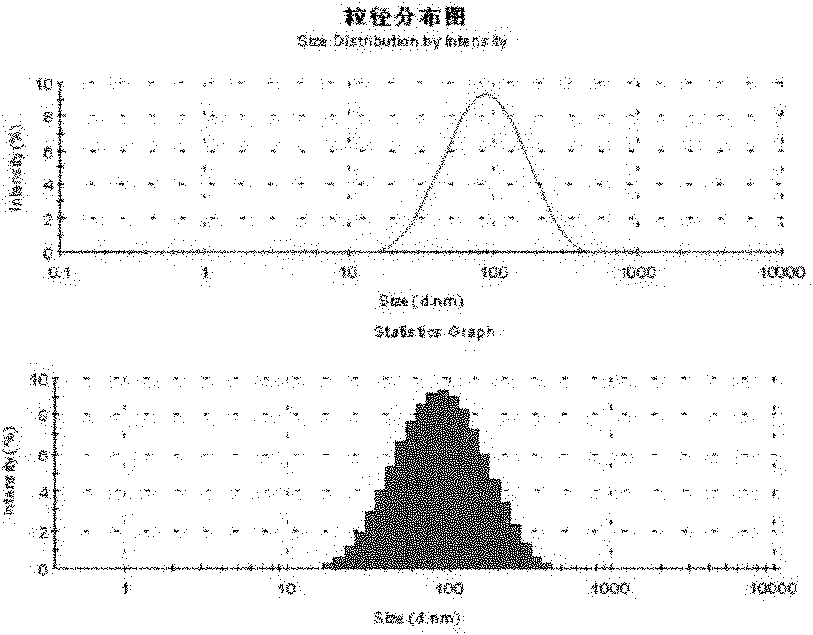

[0032] Embodiment 1 Tanshinone self-microemulsion preparation and particle size determination

[0033] Weigh 4g of medium-chain triglyceride, 4g of polyoxyethylene (40) hydrogenated castor oil, and 2g of 1,2-propylene glycol, and mix the three evenly in a water bath at 60°C to obtain a clear blank self-microemulsion, and then add Salvia miltiorrhiza 100mg of total ketone powder, in a water bath at 60°C to 80°C, shake vigorously with a rapid mixer to fully dissolve tanshinone, and obtain a dark red clear tanshinone self-microemulsion.

[0034] Tanshinone is added 100 times of water dilutions from microemulsion, Malvern laser particle size analyzer (Malvern Zetasizer nano zs 90) measures particle size, the particle size distribution of formed microemulsion is as follows: figure 1 , The average particle size is 79.54nm, the dispersion is uniform, and the polydispersity index PDI is 0.219.

Embodiment 2

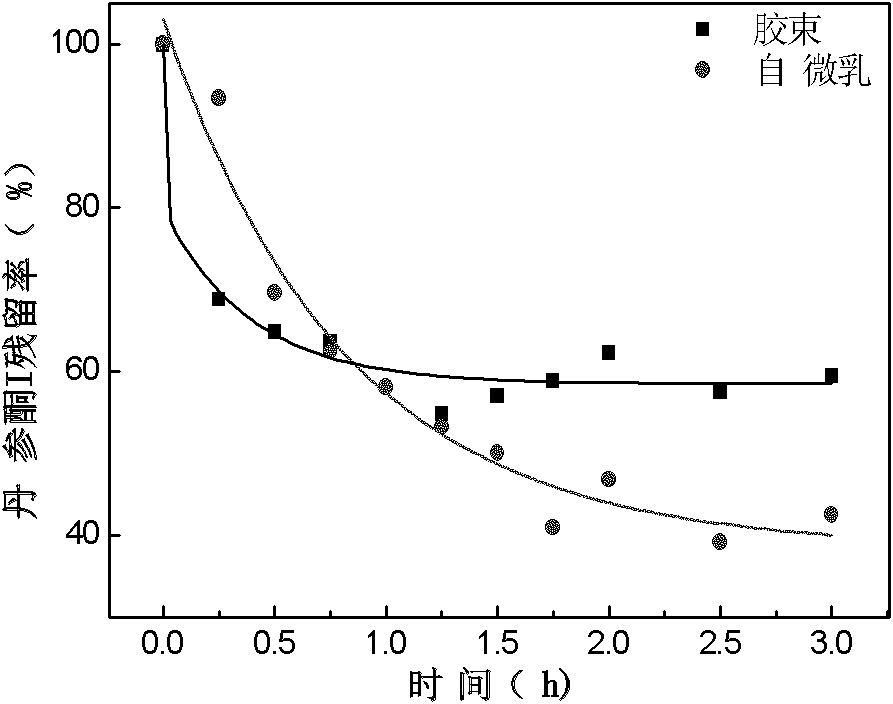

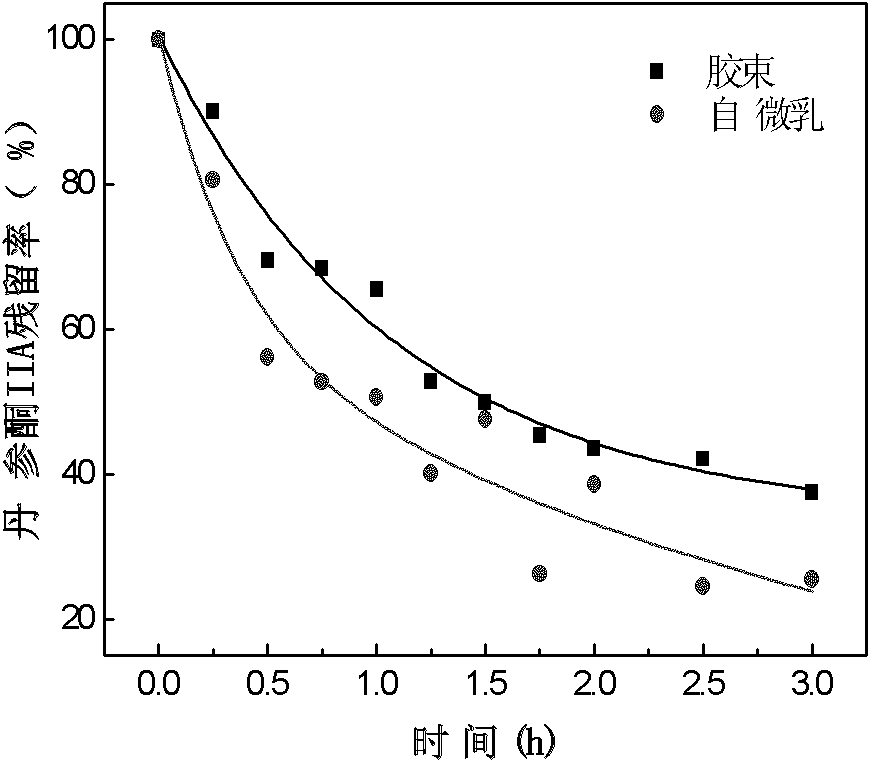

[0035] Embodiment 2 Tanshinone self-microemulsion preparation and absorption evaluation

[0036] Weigh 3 g of medium chain triglyceride, 4.7 g of polyoxyethylene (40) hydrogenated castor oil, and 2.3 g of 1,2-propanediol, and mix the three evenly in a water bath at 60° C. to obtain a clear blank self-microemulsion, and then Add 100 mg of total tanshinone powder, place in a water bath at 60°C to 80°C, and shake vigorously with a rapid mixer to fully dissolve tanshinone to obtain a dark red clear tanshinone self-microemulsion.

[0037]Add tanshinone from the microemulsion to 100 times of water to dilute to obtain the microemulsion for use, and simultaneously prepare 10 g of mixed surfactant according to the ratio of polyoxyethylene (40) hydrogenated castor oil: 1,2-propylene glycol 2:1 (w / w), Add 100 mg of tanshinone powder, shake vigorously in a water bath at 60°C to 80°C to fully dissolve tanshinone, add 100 times of water to dilute to obtain the corresponding tanshinone micel...

Embodiment 3

[0039] Embodiment 3 Preparation of tanshinone self-microemulsion-sodium alginate microspheres

[0040] Weigh 4g of medium-chain triglyceride, 4g of polyoxyethylene (40) hydrogenated castor oil, and 2g of 1,2-propylene glycol, and mix the three evenly in a water bath at 60°C to obtain a clear blank self-microemulsion, and then add Salvia miltiorrhiza 200 mg of total ketone powder, under a water bath at 60°C to 80°C, shake vigorously with a rapid mixer to fully dissolve tanshinone, and obtain a dark red clear tanshinone self-microemulsion.

[0041] Add the above-mentioned tanshinone self-microemulsion to 100 times of 0.75% ~ 2% 100cp sodium alginate solution, 100r min at 37°C -1 Shake at constant temperature for 10 minutes to emulsify completely, and drop 1.1% CaCl into the solution with an electrostatic droplet microcapsule preparation instrument 2 In the gel bath, tanshinone microspheres are formed, which look like Figure 5 , Tanshinone microcapsules are orange-red, smooth,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com