SAN resin composite material and preparation method thereof

A kind of resin composite material, resin technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

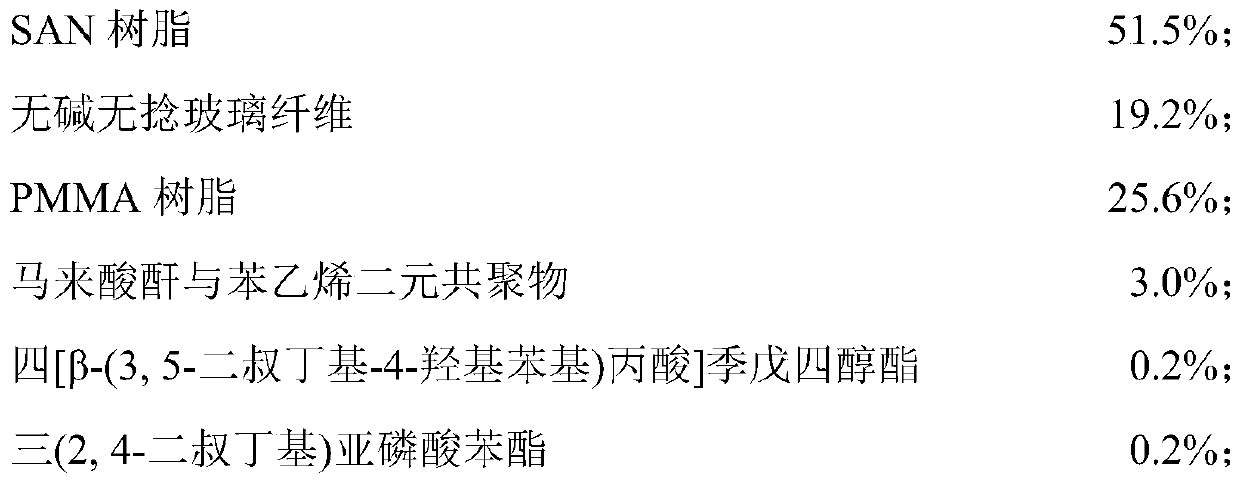

[0038] A kind of SAN resin composite material, comprises following component based on its gross weight:

[0039]

[0040]

[0041] The preparation method of this SAN resin composite material is as follows:

[0042] S1. SAN resin, PMMA resin, maleic anhydride-styrene binary copolymer, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tri(2, 4-di-tert-butyl) phenyl phosphite and zinc stearate are poured into a medium-speed mixer and mixed uniformly to obtain a blend;

[0043] S2. Pour the blend into the storage hopper and extrude it through the twin-screw extruder. At the same time, the glass fiber is added from the natural exhaust port of the extruder, and the weight of the glass fiber entering the extruder per minute and the output per minute are tested. Calculate the weight of the finished product, calculate and control the glass fiber content, mix and extrude to obtain the SAN resin composite material.

Embodiment 2

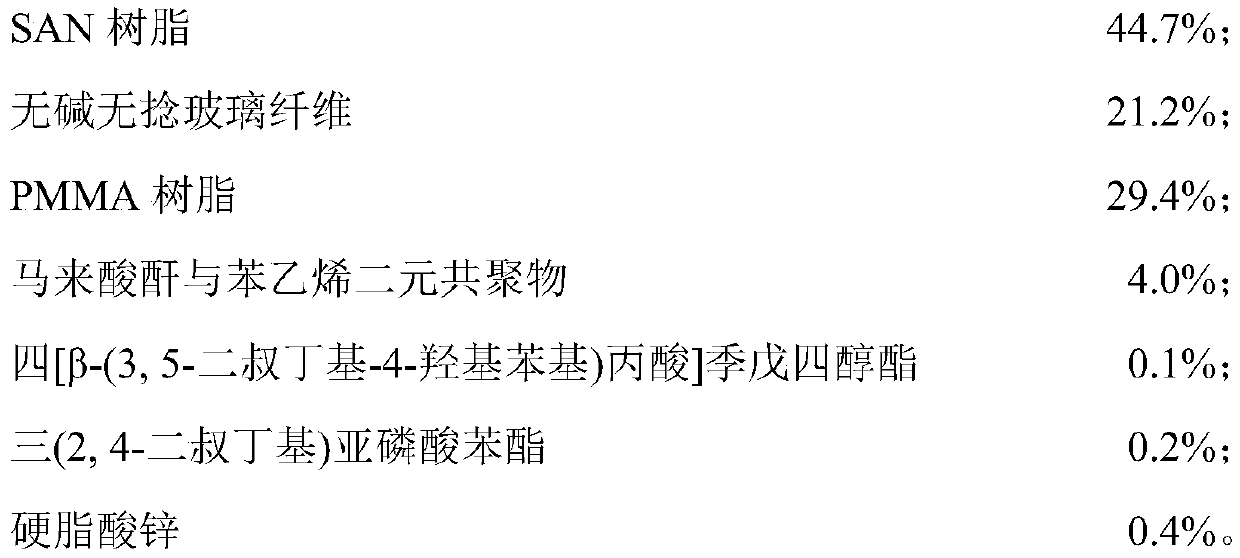

[0045] A kind of SAN resin composite material, comprises following component based on its gross weight:

[0046]

[0047] The preparation method of this SAN resin composite material is as follows:

[0048] S1. SAN resin, PMMA resin, maleic anhydride-styrene binary copolymer, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tri(2, 4-di-tert-butyl) phenyl phosphite and zinc stearate are poured into a medium-speed mixer and mixed uniformly to obtain a blend;

[0049] S2. Pour the blend into the storage hopper and extrude it through the twin-screw extruder. At the same time, the glass fiber is added from the natural exhaust port of the extruder, and the weight of the glass fiber entering the extruder per minute and the output per minute are tested. Calculate the weight of the finished product, calculate and control the glass fiber content, mix and extrude to obtain the SAN resin composite material.

Embodiment 3

[0051] A kind of SAN resin composite material, comprises following component based on its gross weight:

[0052]

[0053]

[0054] The preparation method of this SAN resin composite material is as follows:

[0055] S1. SAN resin, PMMA resin, maleic anhydride-styrene binary copolymer, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tri(2, 4-di-tert-butyl) phenyl phosphite and zinc stearate are poured into a medium-speed mixer and mixed uniformly to obtain a blend;

[0056]S2. Pour the blend into the storage hopper and extrude it through the twin-screw extruder. At the same time, the glass fiber is added from the natural exhaust port of the extruder, and the weight of the glass fiber entering the extruder per minute and the output per minute are tested. Calculate the weight of the finished product, calculate and control the glass fiber content, mix and extrude to obtain the SAN resin composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com