Photochromic double-shell microcapsule and preparation method and application thereof

A photochromic and photochromic material technology, applied in the field of functional polymer material preparation, can solve problems such as poor coating effect and poor stability of single-layer coating layer, and achieve narrow gaps, improved heat resistance, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

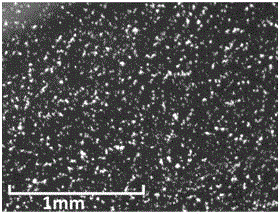

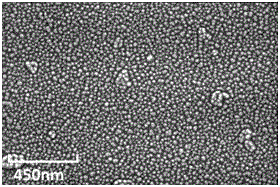

Image

Examples

Embodiment 1

[0048] (1) Weigh 0.5 g of single-shell microcapsules containing bacteriorhodopsin, dissolve them in a mixed solution of 10 mL of absolute ethanol and 1 mL of water, and stir for 0.5 hours to prepare a single-shell capsule dispersion for use;

[0049] (2) Measure 10mL of absolute ethanol and 0.50mL of tetrabutyl titanate, add glacial acetic acid to adjust the pH of the solution to 5, mix them in a beaker and stir for 0.5 hours to prepare a precursor dispersion for later use;

[0050] (3) Add the precursor dispersion prepared in step (2) dropwise to the dispersion of single-shell microcapsules prepared in step (1), control the temperature of the water bath to 40°C, and react for 2 hours, Vacuum suction filtration obtains desired reaction product;

[0051] (4) After washing and filtering the obtained product, put it in an oven and dry it at 60°C for 3 hours to obtain the outer shell of TiO 2 Coated rhodopsin double-shell microcapsules.

Embodiment 2

[0053] (1) Dissolve 5 g of single-shell microcapsules containing bacteriorhodopsin in a mixed solution of 60 mL of absolute ethanol and 1 mL of water, add ammonia water to adjust the pH to 9, and make the single-shell microcapsules of bacteriorhodopsin under nitrogen protection The microcapsules are uniformly dispersed in the solution to obtain the required single-shell microcapsule dispersion of bacteriorhodopsin;

[0054] (2) Mix 3mL vinyltriethoxysilane (VTES), 2mL tetraethyl orthosilicate (TEOS) and 10mL absolute ethanol to obtain a precursor dispersion for later use;

[0055] (3) At 60°C, add the precursor dispersion dropwise to the single-shell microcapsule dispersion of bacteriorhodopsin, keep it warm for 6 hours after the addition, and finally cool to room temperature and settle for 24 hours. Filtration to obtain the desired precipitate;

[0056] (4) After washing and filtering the precipitate obtained in step (5), vacuum-dry it at 60°C to obtain an outer shell of SiO...

Embodiment 3

[0058] (1) Add 5 g of single-shell microcapsules containing bacteriorhodopsin into 10 mL of deionized water, stir and mix evenly to obtain a single-shell microcapsule dispersion of bacteriorhodopsin;

[0059] (2) Prepare an aqueous solution of silane coupling agent KH-560 with a volume concentration of 6.0% according to the conventional method as the first precursor dispersion;

[0060] (3) Prepare 4g / L sodium silicate aqueous solution as the second precursor dispersion according to the conventional method;

[0061] (4) Evenly mix the microcapsule dispersion with 50ml of the first precursor dispersion, turn on the water bath to heat and control the reaction temperature to 60°C, slowly add 4g / L sodium silicate aqueous solution to it, and control the pH of the reaction system The value is around 9.3, and the stirring speed is continuously increased with the increase of the volume of the reaction system. When the pH of the system is 9, stop adding the sodium silicate aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com