UV curable offset color changing ink as well as preparation method and application thereof

A color-changing ink and offset printing technology, which is applied in the field of printing ink, can solve the problems of poor color-changing effect and poor dispersion of color-changing substances, and achieve the effects of improving spreading performance, improving dispersion and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

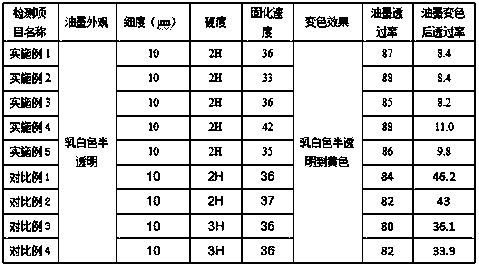

Examples

Embodiment 1

[0098] This example provides a UV curable offset color-changing ink, its formula (mass fraction) is as follows: photochromic powder (spiropyran) 2%, optical microcapsule toner (naphthopyran) 15%, epoxy Acrylate oligomer (polyester modified acrylate) 30%, polyester acrylate oligomer (polyester acrylate) 25%, flexible resin (polyester) 3%, reactive diluent (TPGDA) 4.1% , photoinitiator (1173) 7%, amine co-initiator (6417-TF) 4%, filler (calcium carbonate) 4%, wax powder (polyethylene wax) 1%, spherical micropowder (PMMA) 0.5%, dispersant (SOLSPERSE 39000UV) 4%, defoamer (Tego Airex900) 0.1%, leveling agent (Tego432) 0.3%.

[0099] The preparation method is as follows:

[0100] 1) According to the total formula, 2% of photochromic powder, 15% of photochromic microcapsule toner, 15% of epoxy acrylate oligomer, 15% of polyester acrylate oligomer, and 4.1% of reactive diluent , 4% filler, 1% wax powder, 0.5% spherical micropowder, 4% dispersant, and 0.1% defoamer are sequentially ...

Embodiment 2

[0103] This example provides a UV curable offset color-changing ink, its formula (mass fraction) is as follows: photochromic powder (naphthopyrans) 1%, light-variable microcapsule toner (spiropyran) 7%, light-variable Microcapsule toner (naphthopyran) 9%, epoxy acrylate oligomer (polyester modified epoxy acrylate) 17%, polyester acrylate oligomer (rosin modified polyester acrylate) 26% %, flexible resin (polyether) 2%, reactive diluent (DPGDA) 10.9%, photoinitiator (1173) 4%, photoinitiator (TPO) 4.4%, amine co-initiator (6417-TF) 3%, Filler (calcium carbonate) 5.6%, wax powder (polyethylene wax) 1.2%, spherical micropowder (PMMA) 2%, dispersant (SOLSPERSE 39000UV) 6%, defoamer (Tego Airex900) 0.3%, leveling agent (Tego 432) 0.2%.

[0104] The preparation method is as follows:

[0105] 1) According to the total amount of the formula, 1% of photochromic powder, 7% of photochromic microcapsule toner (spiropyran), 9% of photochromic microcapsule toner (naphthopyran), low epoxy ...

Embodiment 3

[0108] This example provides a UV curable offset color-changing ink, its formula (mass fraction) is as follows: photochromic powder (naphthopyrans) 3%, optical microcapsule toner (naphthopyrans) 12%, Epoxy acrylate oligomer (polyester modified epoxy acrylate) 15%, polyester acrylate oligomer (polyester acrylate) 30%, flexible resin (polyester) 2%, reactive diluent (TMPTMA ) 10%, reactive diluent (TPGDA) 9.8%, photoinitiator (1173) 3%, photoinitiator (TPO) 3%, amine co-initiator (EBECRYL P115) 5%, filler (calcium carbonate) 2%, Wax powder (polyethylene wax) 0.8%, spherical micropowder (PMMA) 1%, dispersant (SOLSPERSE 32000) 3%, defoamer (AX820) 0.1%, leveling agent (Tego 2100) 0.3%.

[0109] The preparation method is as follows:

[0110] 1) According to the total formula, 3% of photochromic powder, 12% of photochromic microcapsule toner, 10% of epoxy acrylate oligomer, 20% of polyester acrylate oligomer, reactive diluent (TMPTMA ) 10%, reactive diluent (TPGDA) 9.8%, filler 2%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com