Preparation and application of novel environmental-friendly cyanuric acid compound stabilizer special for PVC profile

A composite stabilizer and special-shaped material technology, which is applied in the field of organic compound synthesis, can solve problems such as application restrictions and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

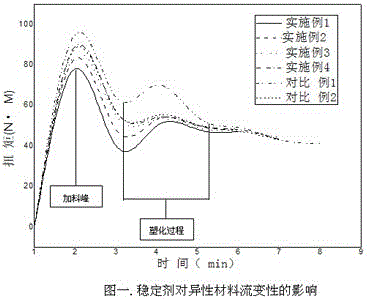

Image

Examples

Embodiment 1

[0030] Step 1, the preparation of zinc cyanurate;

[0031] Take the quality of total reactant as benchmark, prepare zinc cyanurate stabilizer according to following formula:

[0032] Cyanuric acid 62-67 parts

[0034] Silane coupling agent 0.1-0.3 parts

[0035] 3-5 parts of acetic acid

[0036] Add cyanuric acid, zinc oxide, and silane coupling agent into a mechanical cyclone mill according to the above ratio, and grind and blend for 60 minutes under the specific conditions of microwave radiation and acetic acid as a catalyst to obtain a zinc cyanurate stabilizer.

[0037] Step two, compounding;

[0038] Taking the quality of the total reactant as a benchmark, compound the cyanuric acid stabilizer according to the following formula:

[0039] Zinc cyanurate 20 parts

[0040] Auxiliary stabilizer 5 parts

[0041] Lubricant 20 parts

[0042] Antioxidant 5 parts

[0043] Zinc stearate 20 parts

[0044] Calcium stearate 10 parts

[0045] ...

Embodiment 2

[0056] Step 1, the preparation of zinc cyanurate;

[0057] Take the quality of total reactant as benchmark, prepare zinc cyanurate stabilizer according to following formula:

[0058] Cyanuric acid 62-67 parts

[0059] Zinc oxide 60-65 parts

[0060] Silane coupling agent 0.1-0.3 parts

[0061] 3-5 parts of acetic acid

[0062] Add cyanuric acid, zinc oxide, and silane coupling agent into a mechanical cyclone mill according to the above ratio, and grind and blend for 60 minutes under the specific conditions of microwave radiation and acetic acid as a catalyst to obtain a zinc cyanurate stabilizer.

[0063] Step two, compounding;

[0064] Taking the quality of the total reactant as a benchmark, compound the cyanuric acid stabilizer according to the following formula:

[0065] Zinc cyanurate 19 parts

[0066] Auxiliary stabilizer 4.5 parts

[0067] Lubricant 16 parts

[0068] Antioxidant 4.5 parts

[0069] Zinc stearate 16 parts

[0070] 7 parts calcium stearate

[007...

Embodiment 3

[0082] Step 1, the preparation of zinc cyanurate;

[0083] Take the quality of total reactant as benchmark, prepare zinc cyanurate stabilizer according to following formula:

[0084] Cyanuric acid 62-67 parts

[0085] Zinc oxide 60-65 parts

[0086] Silane coupling agent 0.1-0.3 parts

[0087] 3-5 parts of acetic acid

[0088] Add cyanuric acid, zinc oxide, and silane coupling agent into a mechanical cyclone mill according to the above ratio, and grind and blend for 60 minutes under the specific conditions of microwave radiation and acetic acid as a catalyst to obtain a zinc cyanurate stabilizer.

[0089] Step two, compounding;

[0090] Taking the quality of the total reactant as a benchmark, compound the cyanuric acid stabilizer according to the following formula:

[0091] Zinc cyanurate 17 parts

[0092] Auxiliary stabilizer 3.5 parts

[0093] Lubricant 13 parts

[0094] Antioxidant 4 parts

[0095] Zinc stearate 14 parts

[0096] 4 parts calcium stearate

[0097]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com