Preparation method of color-changing plastic cup

A technology of color-changing plastics and pigments, which is applied in the field of plastic cup preparation, can solve the problems of being unable to meet the needs of fashionable people, restricting the appearance and performance of plastic cups, and the single form of plastic cups, so as to achieve rich appearance and fun, design and Reasonable material selection, long-lasting discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

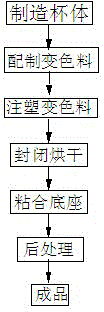

[0018] The specific preparation process of the luminous plastic cup mentioned in the present invention is as follows:

[0019] a) Manufacture the cup body. The material of the cup body is PC, which is prepared by extrusion molding process; the prepared cup body is divided into an outer layer and an inner layer, and the middle layer between the two layers is a cavity structure; the thickness of the outer layer is about The thickness of the inner layer is about 0.6mm, the thickness of the inner layer is about 1mm, and the thickness of the middle layer is about 0.7mm; the upper end surface of the cup body is closed, and the lower end surface is provided with injection holes and vent holes, and the hole diameters are 0.7mm and 0.5mm respectively. The injection molding process of the middle layer is more stable, and it is conducive to the adhesive connection between the cup body and the base;

[0020] b) Prepare the color-changing material. The main components of the color-changing...

Embodiment 2

[0027] The specific preparation process of the luminous plastic cup mentioned in the present invention is as follows:

[0028] a) Manufacture the cup body. The material of the cup body is PC, which is prepared by extrusion molding process; the prepared cup body is divided into an outer layer and an inner layer, and the middle layer between the two layers is a cavity structure; the thickness of the outer layer is about 0.65mm, the thickness of the inner layer is about 1.1mm, and the thickness of the middle layer is about 0.75mm; the upper end surface of the cup body is closed, and the injection hole and the exhaust hole are opened on the lower end surface, and the hole diameters are 0.7mm and 0.5mm respectively. Make the injection molding process of the middle layer more stable, and facilitate the bonding connection between the cup body and the base;

[0029] b) Prepare the color-changing material. The main components of the color-changing material and their percentage ratio ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com