Electrically heated hollow glass and manufacturing method thereof

An electric heating and electric heating film technology, applied in parallel glass structures, lighting and heating equipment, building structures, etc., can solve the problems of reducing the insulation effect of insulating glass, single decorative effect, no decorative effect, etc., and achieve the appearance effect. Diversification, improving aesthetics, and improving the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

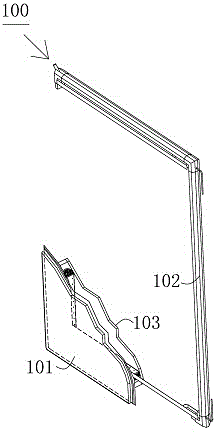

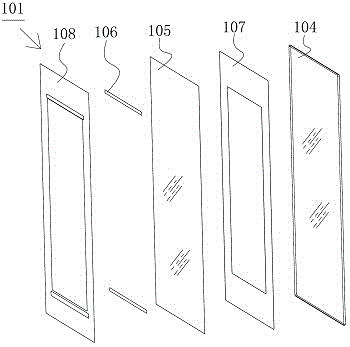

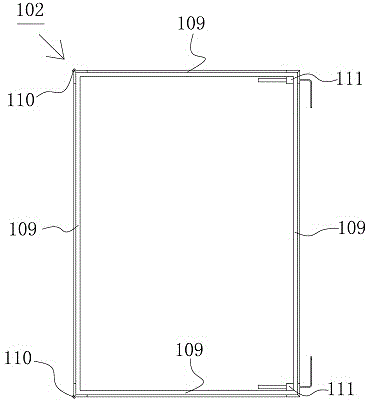

[0040] like figure 1 , figure 2 As shown, an electrically heated insulating glass 100 with decorative effect of the present invention includes an outer glass 101 , a spacer assembly 102 and an inner glass 103 , and the outer glass 101 and the inner glass 103 are respectively provided on the front and rear of the spacer assembly 102 Both sides. The outer glass 101 includes a glass body 104, an electric heating film 105 and a conductive silver paste strip 106 in sequence from front to back. A decorative film 107 is arranged between the glass body 104 and the electric heating film 105, so that the appearance of the product is varied. It can improve the aesthetics of the product without adding decorative glass, reduce the number and weight of parts, and reduce the cost of the product.

[0041] In this embodiment, the decorative film 107...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com